Waste gas filtering equipment

A waste gas filtration and equipment technology, which is applied in the direction of dispersed particle separation, chemical instruments and methods, combined devices, etc., can solve the problems of untreated, reduced filtering effect, and low service life, so as to reduce waste and pollution of water resources, equipment, etc. The effect of low investment cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

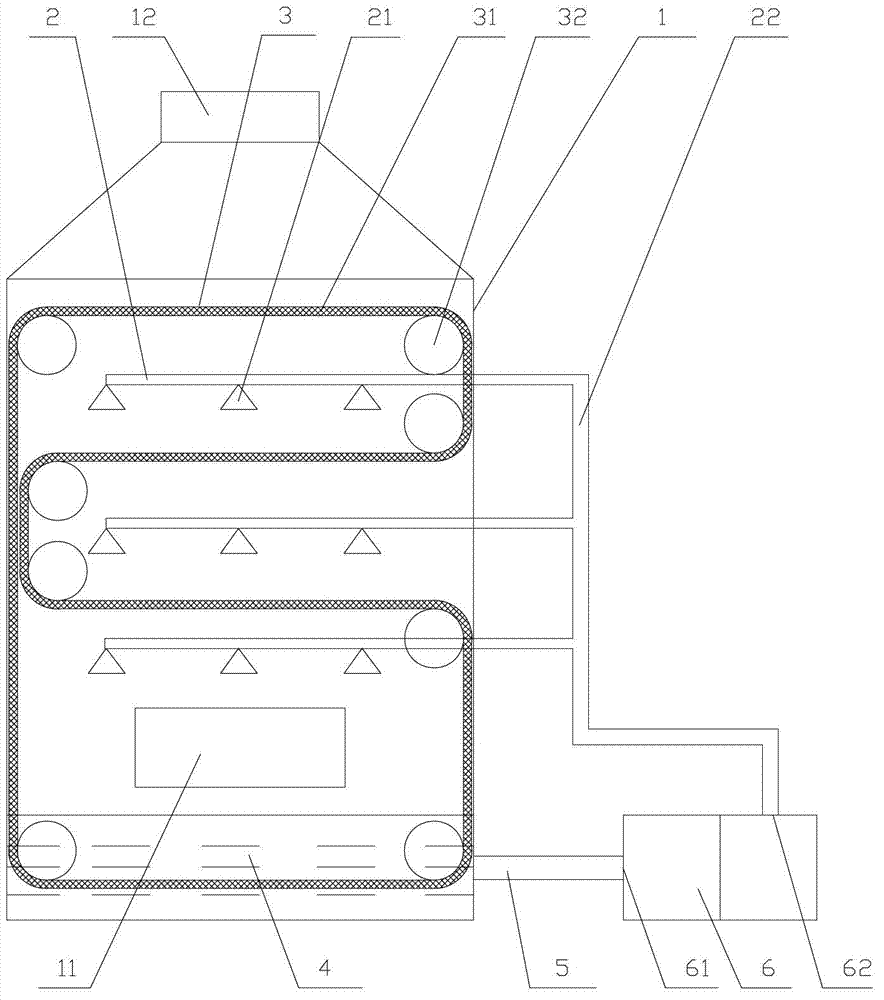

[0013] Implementation Option 1: Reference figure 1 , The filter equipment includes a main box 1, a spray cooling system 2, a three-stage filter system 3, a scrubbing water tank 4, and an oil-water separation treatment circulating water tank 6. The main box contains an air inlet 11 and an air outlet 12 . The spray cooling system 2, the three-stage filter system 3 and the scrubbing water tank 4 are all located in the main box body 1, and the scrubbing water tank 4 is located below the main box body 1; the spray cooling system includes a spray rack 21 and a water supply pipe 22, The filter system includes a drum 32 and a filter cloth curtain 31. The spray frame of the spray cooling system is located under each layer of filter cloth curtain 31 in the filter system. The drum 32 is distributed on the two side walls of the main box 1, and the filter cloth curtain 31 is wound back and forth. Set on the drum 32, the two drums 32 located at the bottom of the two side walls are connecte...

Embodiment approach 2

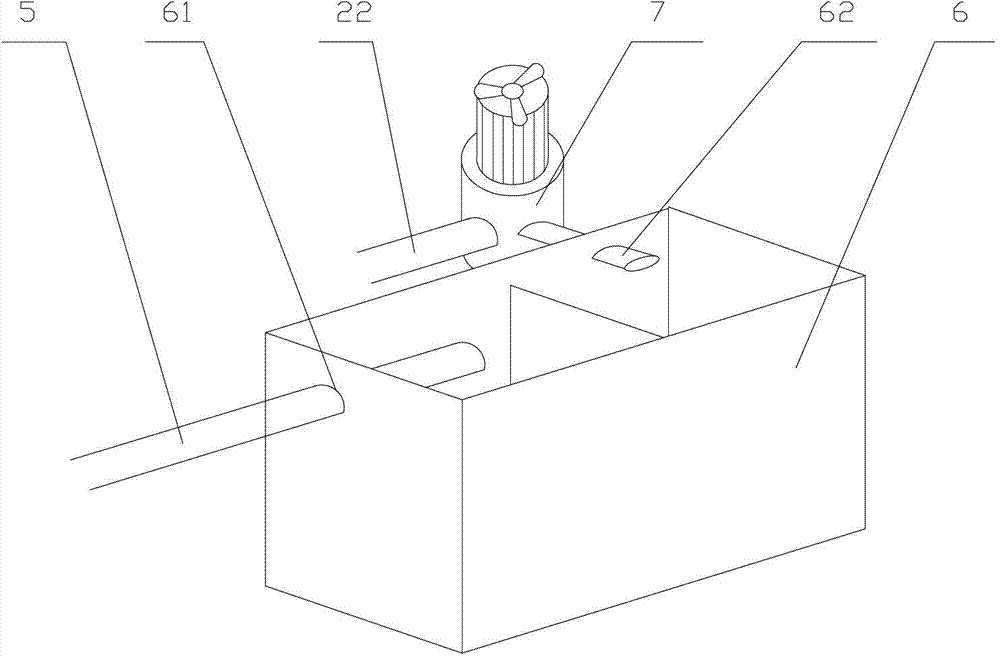

[0015] Implementation Option 2: Reference figure 1 , figure 2 , The filter equipment includes a main box 1, a spray cooling system 2, a three-stage filter system 3, a scrubbing water tank 4, and an oil-water separation treatment circulating water tank 6. The main box contains an air inlet 11 and an air outlet 12 . The spray cooling system 2, the three-stage filter system 3 and the scrubbing water tank 4 are all located in the main box body 1, and the scrubbing water tank 4 is located below the main box body 1; the spray cooling system includes a spray rack 21 and a water supply pipe 22, The filter system includes a drum 32 and a filter cloth curtain 31. The spray frame of the spray cooling system is located under each layer of filter cloth curtain 31 in the filter system. The drum 32 is distributed on the two side walls of the main box 1, and the filter cloth curtain 31 is wound back and forth. Set on the drum 32, the two drums 32 located at the bottom of the two side walls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com