Detachable pay-off special tool

A special tool and detachable technology, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of inconvenient operation, easy damage and easy damage of threading rods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The following will be described in conjunction with the accompanying drawings and specific embodiments.

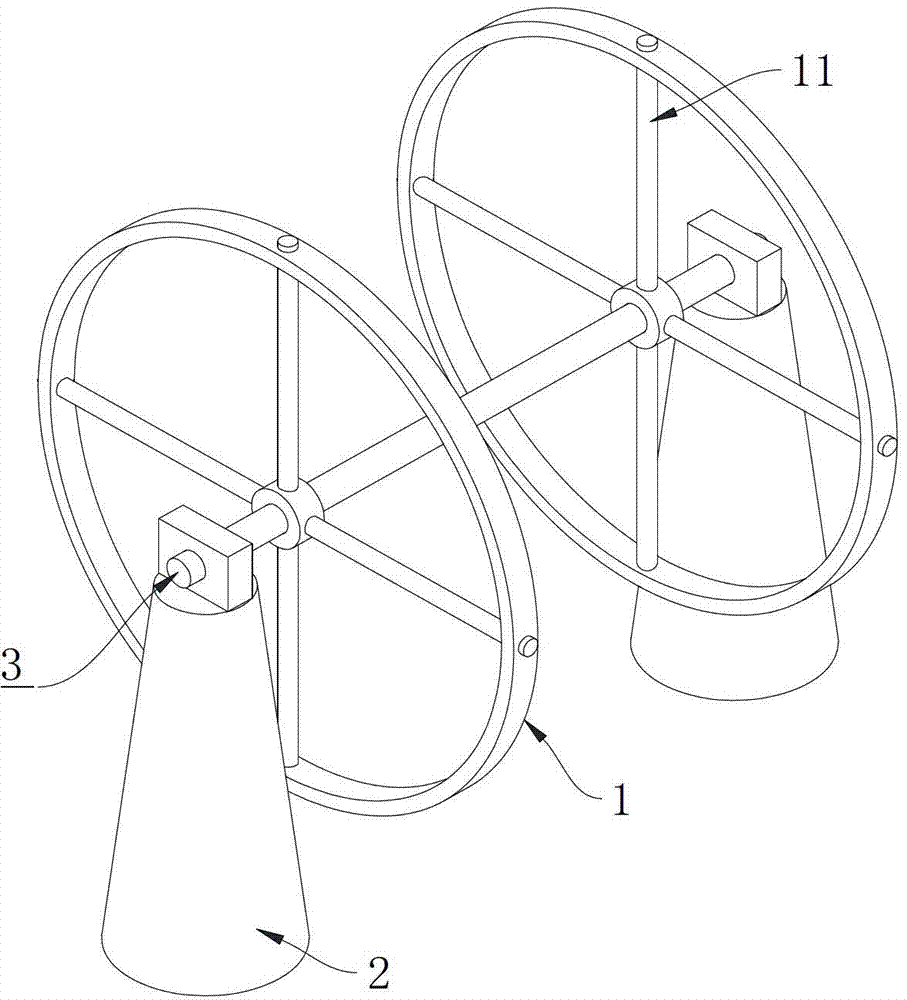

[0010] see figure 1 . The detachable wire-laying special tool described in this embodiment includes two brackets 3 , a load-bearing shaft 2 and two wire reels 1 . They are respectively installed at the two ends of the load-bearing shaft 2, and two wire reels 1 are installed on the load-bearing shaft 2 between the two brackets 3. The structure of the reel 1 is as follows: a plurality of connecting rods 11 are connected to the bearing and the outer ring, and the bearing is sleeved on the bearing shaft 2 . The connection method may be a fixed connection, or may be connected by assembling. The outer surface of the bearing is uniformly provided with 4 blind holes for the insertion of the connecting rods, and the outer ring is evenly provided with 4 through holes for the insertion of the connecting rods. After the connecting rod is inserted into the through hole and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com