All-terrain vehicle stepless speed change cooling system device

A technology of infinitely variable speed and cooling device, applied in the direction of gear lubrication/cooling, etc., can solve the problems of lack of heat dissipation and cooling in the transmission system, not considering belt slippage and wear and heating, inconvenient assembly and maintenance, etc. Disassembly and maintenance, small footprint, and the effect of reducing components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

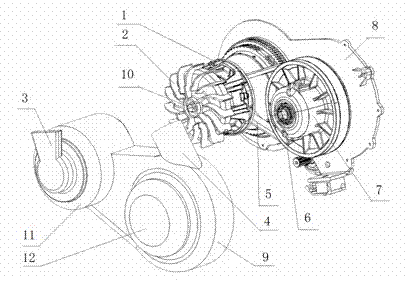

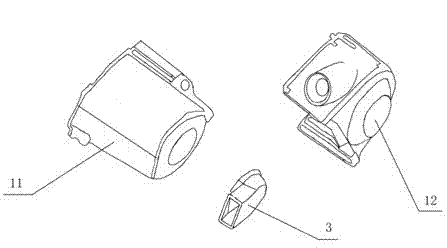

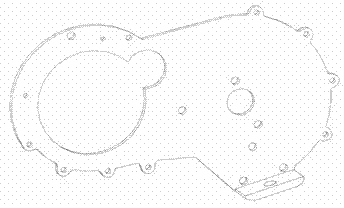

[0012] Such as figure 1 As shown, the cooling device of the continuously variable transmission system of an all-terrain vehicle includes a driving wheel 1, a cooling fan 2, an air inlet pipe joint 3, an exhaust port 4, a transmission belt 5, a hexagonal bolt 6, a driven wheel 7, an outer cover installation sealing plate 8, Outer cover 9, hexagonal flange bolts 10; cooling fan 2 is connected with continuously variable speed driving wheel 1 through hexagonal flange bolts 10, continuously variable speed driving wheel 1 is connected with driven wheel 7 through transmission belt 5, continuously variable speed driving The wheel 1 is fixed on the outer cover installation sealing plate 8 through the hexagonal flange bolt 10, the driven wheel 7 is fixed on the outer cover installation sealing plate 8 through the hexagonal bolt 6, and the outer cover 9 is provided with an air inlet pipe joint 3 and an exhaust port 4. The outer cover 9 is fixed on the outer cover mounting plate seal 8 by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com