Water membrane activated carbon filter tank

A technology of activated carbon filter plate and filter cabinet, applied in the field of filter cabinet, can solve the problem of inability to process multiple wastes at the same time, and achieve the effect of improving speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

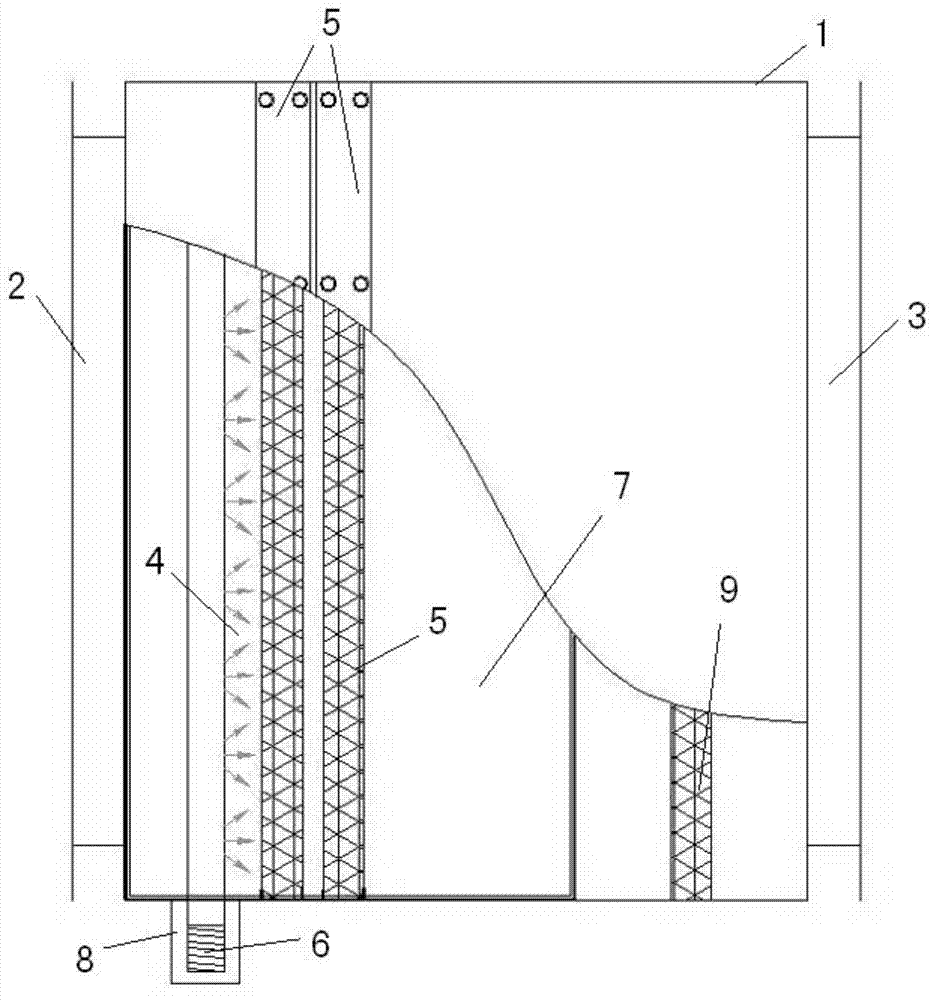

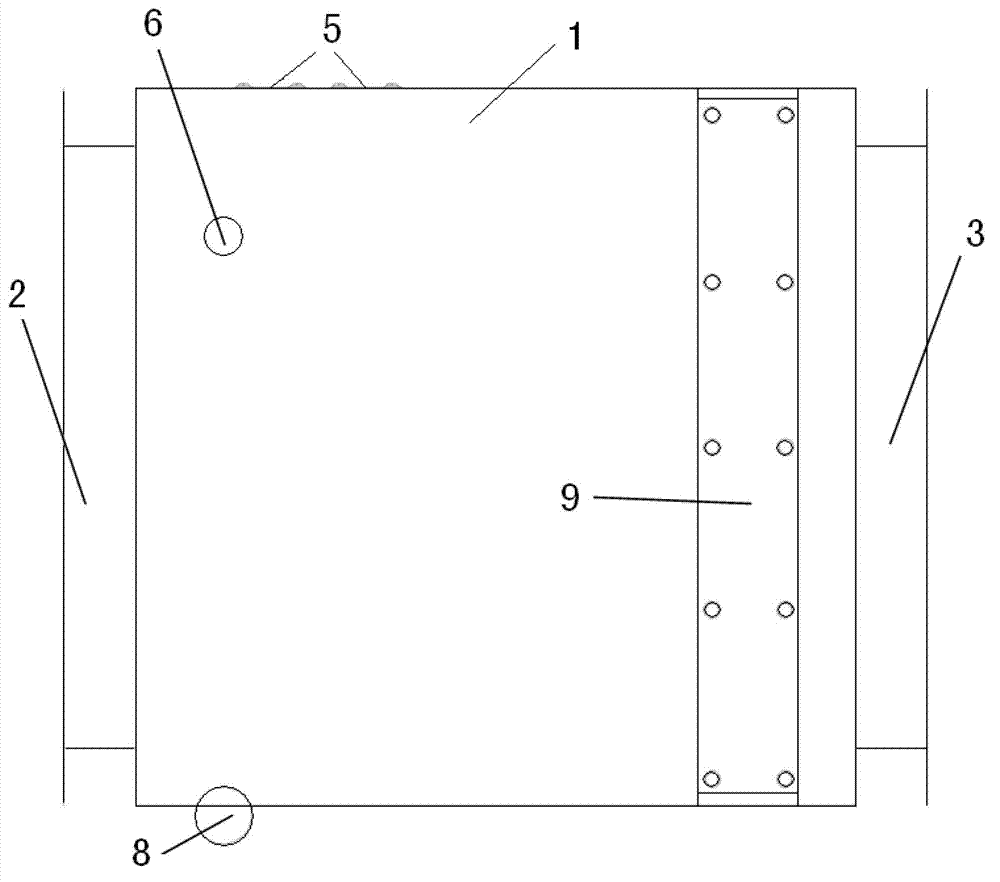

[0010] Such as figure 1 , figure 2 As shown, a water film activated carbon filter cabinet provided by the present invention adopts a cabinet structure and is installed on the exhaust duct of the clothing flame retardant performance testing laboratory. It includes a housing 1, an air inlet 2, an air outlet 3, a spray pipe 4, a water film filter plate 5, a water inlet 6, a sump 7, a water outlet 8 and an activated carbon filter plate 9. The housing 1 is used to accommodate Spray pipe 4, water film filter plate 5, sump 7 and active carbon filter plate 9.

[0011] One end of the housing 1 is provided with an air inlet 2, and the other end is provided with an air outlet 3, through which the water film activated carbon filter cabinet of the present invention is installed on the exhaust duct. Near the side of the air inlet 2, a spray pipe 4 and two layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com