Composite interior trim plate of passenger automobile and production method of composite interior trim plate

A technology for interior panels and passenger cars, which is applied to vehicle parts, transportation and packaging, etc. It can solve the problems of inconvenient welding of PVC leather and inability to realize high-frequency heat sealing, and achieve clear and uniform characteristic lines and firm welding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

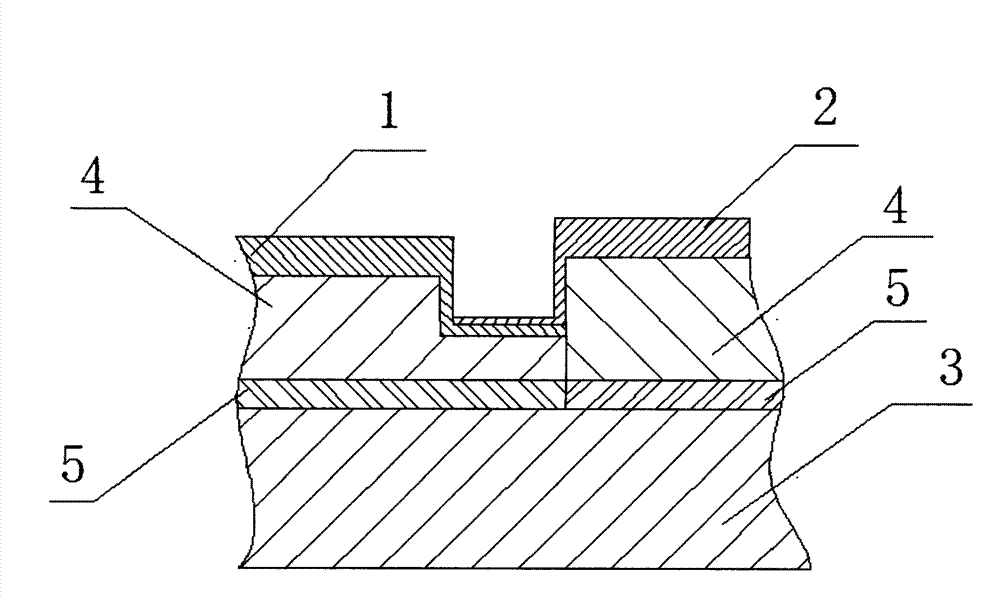

[0010] A composite interior panel for a passenger car, comprising a polyester fabric 1 covered with polyurethane soft foam 4 and non-woven fabric 5, polyvinyl chloride leather 2 covered with polyurethane soft foam 4 and non-woven fabric 5, and a hemp fiber material substrate 3 , which is characterized in that the overlap between the polyester fabric 1 covered with polyurethane soft foam 4 and non-woven fabric 5 and the polyvinyl chloride leather 2 covered with polyurethane soft foam 4 and non-woven fabric 5 adopts a high-frequency heat sealing method A layered structure welded together. The production method of the passenger car composite interior panel includes blanking molding of polyester fabric 1 and polyvinyl chloride leather 2, welding of polyester fabric 1 and polyvinyl chloride leather 2, molding of hemp fiber material substrate 3, and spraying of adhesive The technological process of activation, positioning and compounding, flanging modification, and accessory assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com