Humic acid synergia compound fertilizer and preparation method thereof

A technology of humic acid and compound fertilizer, which is applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of difficult popularization and application, high production cost, complicated process, etc., and achieves the effect of simple process, low cost and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

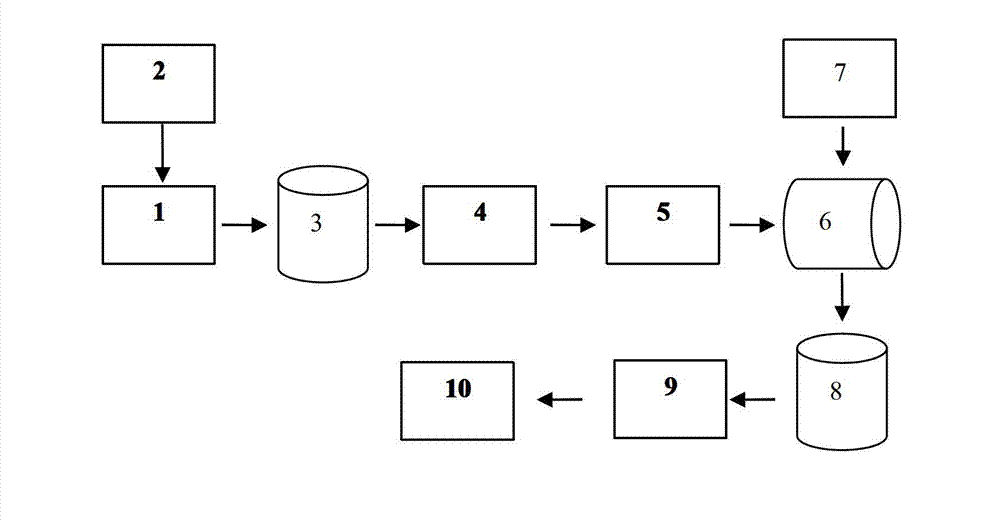

Method used

Image

Examples

Embodiment 1

[0072] Embodiment 1: produce humic acid synergistic compound fertilizer of the present invention

[0073] Crush the weathered coal to 80 mesh, add 0.3% by weight sodium hydroxide solution with a concentration 10 times its weight, heat and continue to boil for 20 minutes, then carry out centrifugation to obtain a supernatant, and concentrate the supernatant to the solid The content of humic acid is 8% by weight to obtain humic acid synergist liquid A.

[0074] Put the humic acid synergist liquid A and urea into the urea melting tank at a weight ratio of 6:62, and fully melt at 120°C to obtain a humic acid-urea molten liquid.

[0075] The granulation materials monoammonium phosphate, potassium sulfate, bentonite and monocalcium phosphate are mixed according to the weight ratio of 18.2:24:10:8.6 and put into the drum granulator.

[0076] Then, adjust the pressure of the pressure pump to 15 atmospheres, spray the previously prepared co-melt on the granulated material at a flow ra...

Embodiment 2

[0077] Embodiment 2: produce humic acid synergistic compound fertilizer of the present invention

[0078] Pulverize lignite to 100 mesh, add 0.5% by weight potassium hydroxide solution with a concentration 12 times its weight, heat and continue to boil for 25 minutes, then carry out centrifugation to obtain a supernatant, and concentrate the supernatant to the solid When the content is 0.5%, humic acid synergist liquid A is obtained.

[0079] Put the humic acid synergist liquid A and urea into the urea melting tank at a ratio of 1:32, and fully melt it under the condition of 110°C to obtain the humic acid urea molten liquid.

[0080] The granulation materials monoammonium phosphate, potassium sulfate, bentonite and calcium dihydrogen phosphate are mixed according to the weight ratio of 32.6:30:6.5, and then put into the drum granulator.

[0081] Then, adjust the pressure of the pressure pump to 12 atmospheres, spray the previously prepared co-melt on the granulated material a...

Embodiment 3

[0082] Embodiment 3: produce humic acid synergistic compound fertilizer of the present invention

[0083] Mix the sulfuric acid aqueous solution with a concentration of 0.1% by weight and sodium humate at a weight ratio of 3:1, stir thoroughly for 15 minutes, and then perform centrifugation to obtain a supernatant, and concentrate the supernatant to a solid content of 0.5% by weight , to obtain humic acid synergist solution B.

[0084] Put the humic acid synergist liquid B and urea into the urea melting tank at a ratio of 4:40, and fully melt at 125°C to obtain a humic acid-urea melt.

[0085] The granulation materials monoammonium phosphate, potassium sulfate, bentonite, calcium magnesium phosphate fertilizer are mixed according to the ratio of 21.7:20:8:12 and put into the drum granulator.

[0086] Then, adjust the pressure of the pressure pump to 18 atmospheres, spray the previously prepared co-melt on the granulated material at a flow rate of 1200kg / h, and rotate with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com