Humic acid synergistic ammonium bicarbonate fertilizer and production method thereof

A technology of ammonium bicarbonate and production method, applied in fertilizer mixture, fertilization device, application, etc., can solve problems such as difficult operation, strong alkalinity, and nitrogen volatilization loss, so as to improve product quality, enhance the ability to absorb nutrients, reduce Effect of ammonia volatilization loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

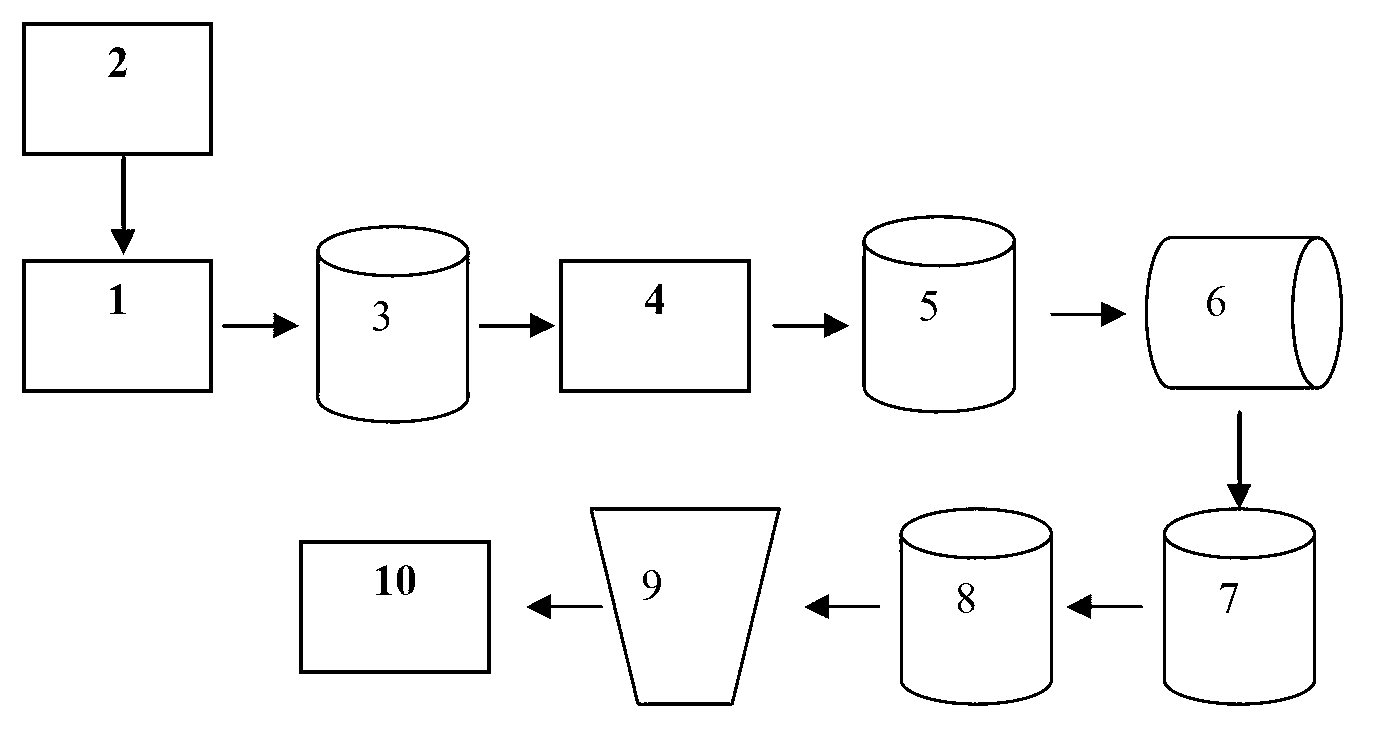

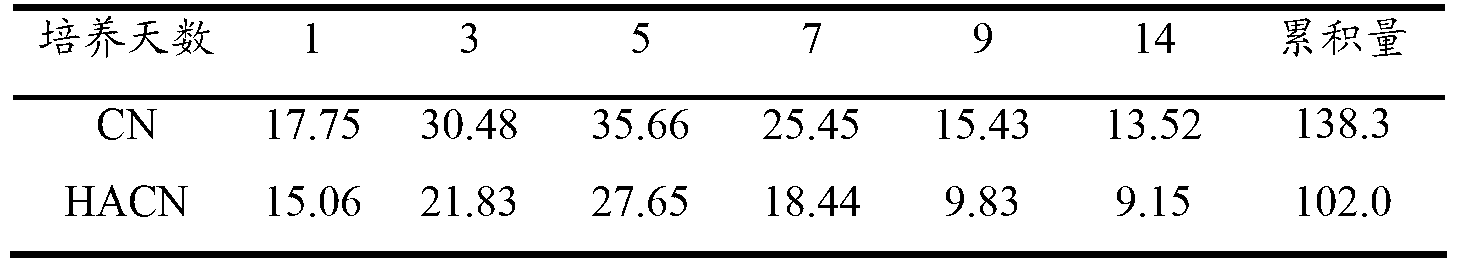

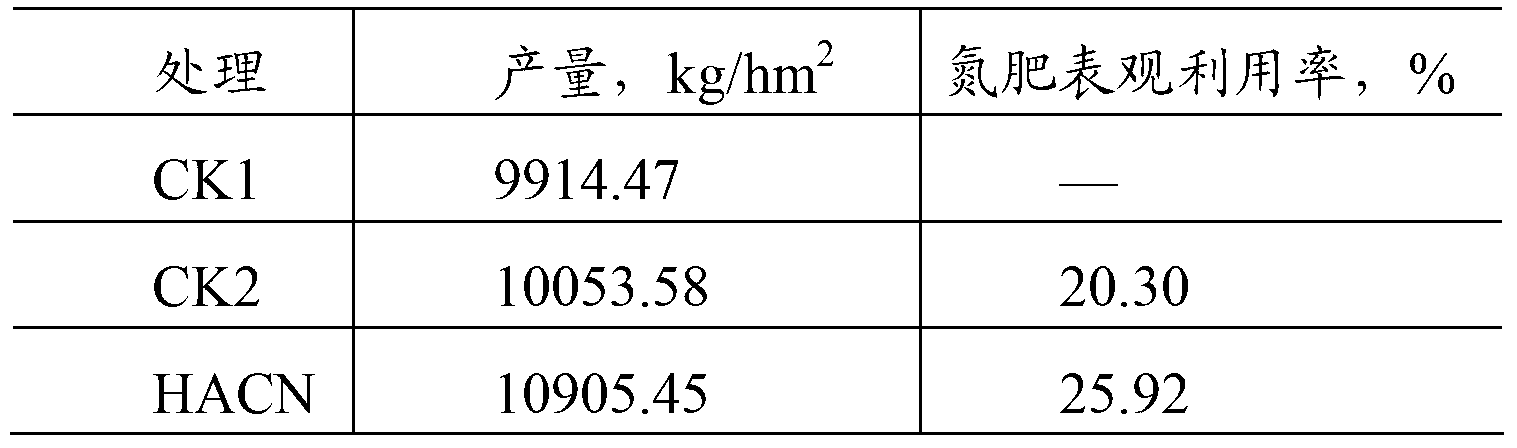

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1: the production of humic acid synergistic ammonium bicarbonate fertilizer of the present invention

[0071] The implementation steps of this embodiment are as follows:

[0072] A. Preparation of humic acid synergist:

[0073] Use a pulverizer sold by Weifang Zhengyuan Powder Engineering Equipment Co., Ltd. under the trade name LHB self-distributing micro-powder machine, pulverize the raw material weathered coal to 80 mesh, and then add 0.1% sodium hydroxide with a concentration of 0.1% by weight, which is 10 times its weight Aqueous solution, heated and continued to boil for 20 minutes, then centrifuged using a centrifuge sold by Jiangsu Mudan Centrifuge Manufacturing Co., Ltd. under the trade name SGZ type scraper discharge centrifuge, and the supernatant obtained was used by Shanghai Dingtai Evaporator Co., Ltd. The concentrator sold by the company under the trade name vacuum decompression concentration tank is heated and concentrated at a temperature of...

Embodiment 2

[0078] Embodiment 2: the production of humic acid synergistic ammonium bicarbonate fertilizer of the present invention

[0079] The implementation steps of this embodiment are as follows:

[0080] A. Preparation of humic acid synergist:

[0081] Use the pulverizer sold by Qingdao Jimo Superfine Pulverizer Factory under the trade name Turbine Pulverizer, pulverize the raw material weathered coal to 100 mesh, add 12 times its weight, and the concentration is 0.5% sodium hydroxide aqueous solution by weight, and the heating continues Boil for 30 minutes, then use a centrifuge sold by Shanghai Chemical Machinery Factory Co., Ltd. under the trade name of horizontal screw discharge sedimentation centrifuge, and the obtained clear liquid is concentrated by Wenzhou Benuo Machinery Co., Ltd. under the trade name SN series double-effect energy-saving The vacuum concentrator sold by the company is heated and concentrated at a temperature of 50-80°C and a pressure of 100-120kpa until the...

Embodiment 3

[0086] Embodiment 3: the production of humic acid synergistic ammonium bicarbonate fertilizer of the present invention

[0087] The implementation steps of this embodiment are as follows:

[0088] A. Preparation of humic acid synergist:

[0089] Use the pulverizer sold by Qingdao Jimo Superfine Pulverizer Factory under the trade name Turbine Pulverizer, pulverize the raw material weathered coal to 90 mesh, add 12 times its weight, and the concentration is 0.2% sodium hydroxide aqueous solution by weight, and the heating continues Boil for 25 minutes, and then centrifuge using a centrifuge sold by Suzhou Batuo Centrifuge Manufacturing Co., Ltd. as an SB three-legged closed centrifuge. The supernatant obtained is commercialized by Changzhou Shenghang Pharmaceutical Equipment Co., Ltd. The vacuum concentrator sold by the famous ZN series vacuum decompression concentrator is heated and concentrated at a temperature of 50-80°C and a pressure of 100-150kpa until the solid content i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com