Algae synergistic high-tower compound fertilizer and production method thereof

A technology of seaweed synergist and compound fertilizer, applied in fertilization device, fertilizer mixture, application and other directions, can solve the problems of low production capacity, high production cost, complex process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

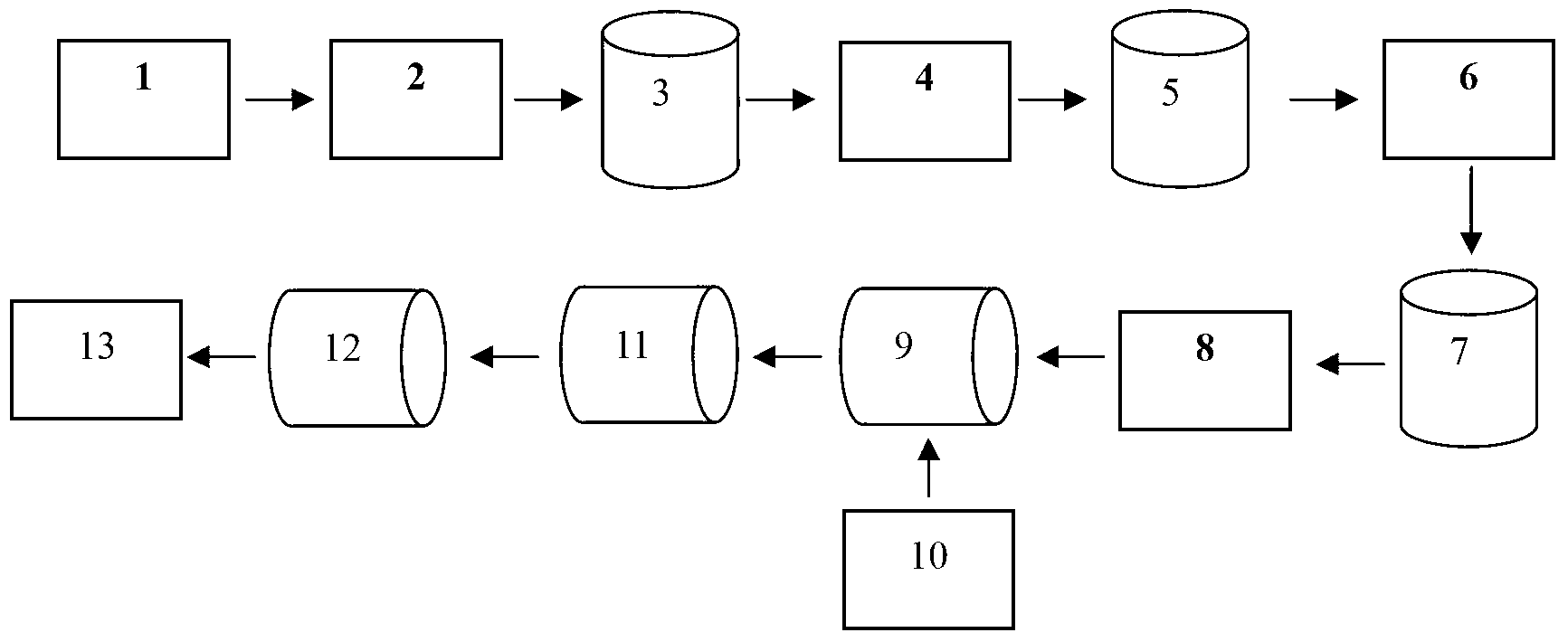

Method used

Image

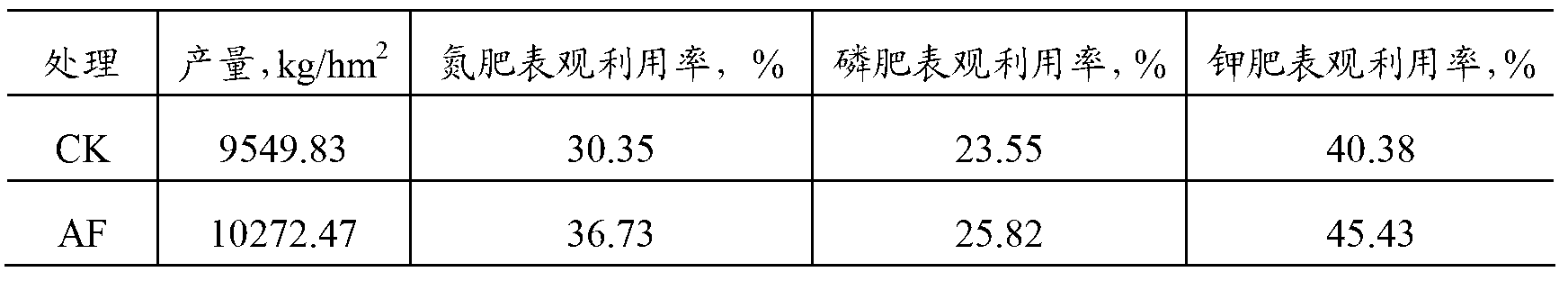

Examples

Embodiment 1

[0125] Embodiment 1: the production of seaweed synergistic ammonium bicarbonate fertilizer of the present invention

[0126] The implementation steps of this embodiment are as follows:

[0127] A. Preparation of seaweed synergistic liquid:

[0128] (1) Add 125 parts by weight of cornmeal and 30 parts by weight of sucrose to 1010 parts by weight of 20 mesh kelp natural seaweed raw material powder, stir the mixture evenly, adjust the water content of the mixture to 30% by weight with water, and then oxidize the mixture with hydrochloric acid or hydrogen Sodium aqueous solution adjusts its pH to 7.5, so that a kind of natural seaweed fermentation material is obtained;

[0129] (2) Add 0.8 parts by weight of the EM flora fermentation liquid sold by Jilin Great Wall Agricultural Machinery Biotechnology Co., Ltd. and 0.5 parts by weight of sucrose to 8 parts by weight of water, mix well and store in an airtight container for 26 hours, thus obtaining an EM fermented flora stock sol...

Embodiment 2

[0140] Embodiment 2: the production of seaweed synergistic ammonium bicarbonate fertilizer of the present invention

[0141] The implementation steps of this embodiment are as follows:

[0142] A. Preparation of seaweed synergistic liquid:

[0143] (1) Add 140 parts by weight of cornmeal and 80 parts by weight of glucose to 900 parts by weight of 100 mesh kelp natural seaweed raw material powder, stir the mixture evenly, adjust the water content of the mixture to 38% by weight with water, and then oxidize it with sulfuric acid or hydrogen Potassium aqueous solution is adjusted its pH to 7.0, obtains a kind of natural seaweed fermentation material like this;

[0144] (2) Add 1.2 parts by weight of EM flora fermentation broth sold by Jilin Great Wall Agricultural Machinery Biotechnology Co., Ltd. or Anhui Guangyu Biotechnology Co., Ltd. and 0.8 parts by weight of glucose to 12 parts by weight of water, mix well and store in an airtight container for 28 Hour, so obtain a kind of ...

Embodiment 3

[0155] Embodiment 3: the production of seaweed synergistic ammonium bicarbonate fertilizer of the present invention

[0156] The implementation steps of this embodiment are as follows:

[0157] A. Preparation of seaweed synergistic liquid:

[0158] (1) Add 162 parts by weight of cornmeal and 42 parts by weight of fructose to 1150 parts by weight of 60 orders of Hijiki natural seaweed raw material powder, and after the mixture is stirred evenly, adjust the water content of the mixture to 42% by weight with water, and then use nitric acid or Sodium carbonate aqueous solution is adjusted to its pH to 8, obtains a kind of natural seaweed fermentation material like this;

[0159] (2) Add 0.1 parts by weight of EM flora fermentation liquid sold by Anhui Guangyu Biotechnology Co., Ltd. and 1.2 parts by weight of fructose to 0.5 parts by weight of water, mix well and store in an airtight container for 20 hours, thus obtaining a kind of EM fermentation bacteria group stock solution; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com