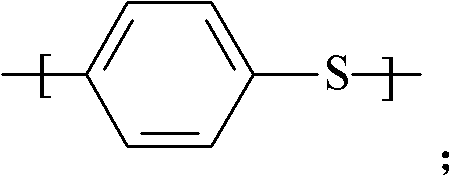

Polyphenylene sulfide composition and fibers thereof

A technology of polyphenylene sulfide and composition, applied in the field of polyphenylene sulfide composition and its fibers, can solve the problems of hyperbranched PPS without commercial products, broken ends, and difficult to realize industrialization and commercialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation of the composition of the present invention adopts a conventional method in the industry, that is, directly mixing polyester and polyphenylene sulfide with a linear structure according to the required ratio.

[0029] The spinning of the fiber of the present invention adopts conventional methods and devices for spinning polyphenylene sulfide fibers in the industry. The spinning process includes in sequence: pre-drying of the spinning raw material (the polyphenylene sulfide composition of the present invention), spinning, and stretching.

[0030] The pre-drying equipment can adopt a drum oven (such as ZG-type dynamic vacuum dryer). The spinning equipment can adopt the melt spinning machine ABEΦ25 of ABE Company of Japan, and the drawing equipment can adopt the drawing machine Barmag 30B of Barmag Spinzwirn Company of Germany.

[0031] Performance Testing

[0032] Spinnability: Measured by the maximum draw ratio and the number of broken ends.

[0033] Th...

Embodiment 1

[0039] raw material

[0040] PPS: purchased from Japan Polyplastics Corporation, the product name is 0316C.

[0041] PET: intrinsic viscosity 0.64

[0042] PBT: intrinsic viscosity 1.0

[0043] spinning equipment

[0044] ZG-type dynamic vacuum dryer (drum oven)

[0045] Melt spinning machine ABE Φ25, purchased from Japan ABE Company

[0046] Stretching machine Barmag 30B, purchased from Germany Barmag Spinzwirn company

[0047] Instruments for testing fiber breaking strength and elongation at break: Shimadzu AGS500 fiber strength machine, purchased from Japan Shimadzu Corporation

[0048] Preparation of the composition: 1 weight part of the above-mentioned PET and 99 weight parts of the above-mentioned PPS were uniformly mixed in a mixer.

[0049] Fiber preparation

[0050] Pre-drying: Put the PET and PPS composition obtained by mixing above in a ZG-type dynamic vacuum dryer, and pre-dry at 150° C. for 72 hours.

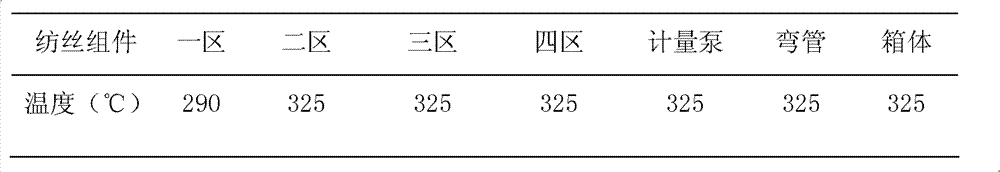

[0051] Spinning and drawing:

[0052] Spinning is car...

Embodiment 2

[0066] The raw materials and steps are the same as in Example 1, except that: 3 parts by weight of PET and 97 parts by weight of PPS are used to prepare the composition and perform spinning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com