Dispersion optical-fiber type photo-bioreactor with inserted spiral band

A photobioreactor and helical tie technology, applied in the field of dispersive optical fiber photobioreactors, can solve the problems of increased bubble polymerization, splitting, uneven light distribution, low carbon fixation efficiency, etc., so as to prolong residence time and improve transmission. quality efficiency and the effect of improving carbon sequestration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

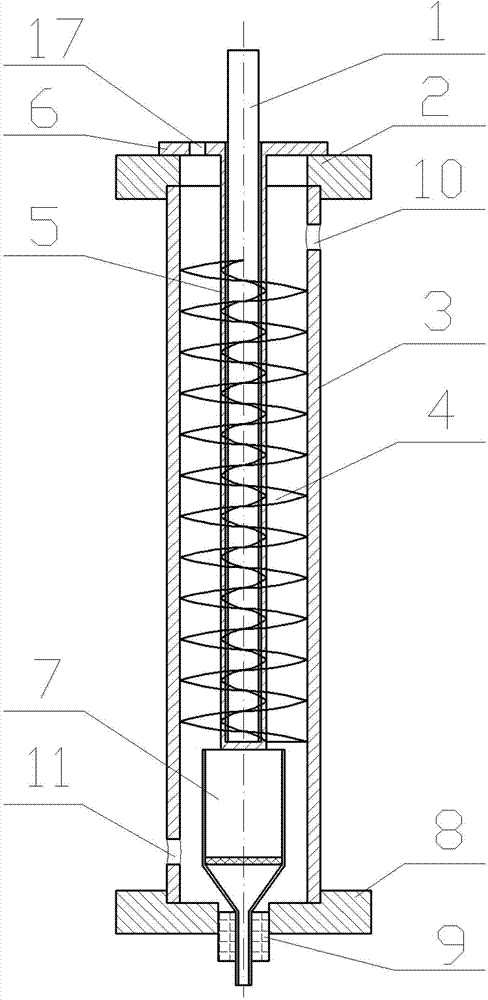

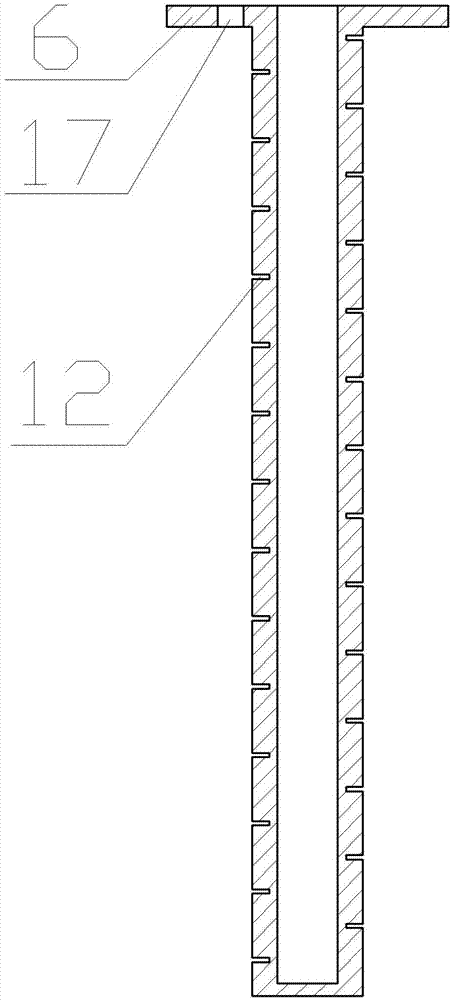

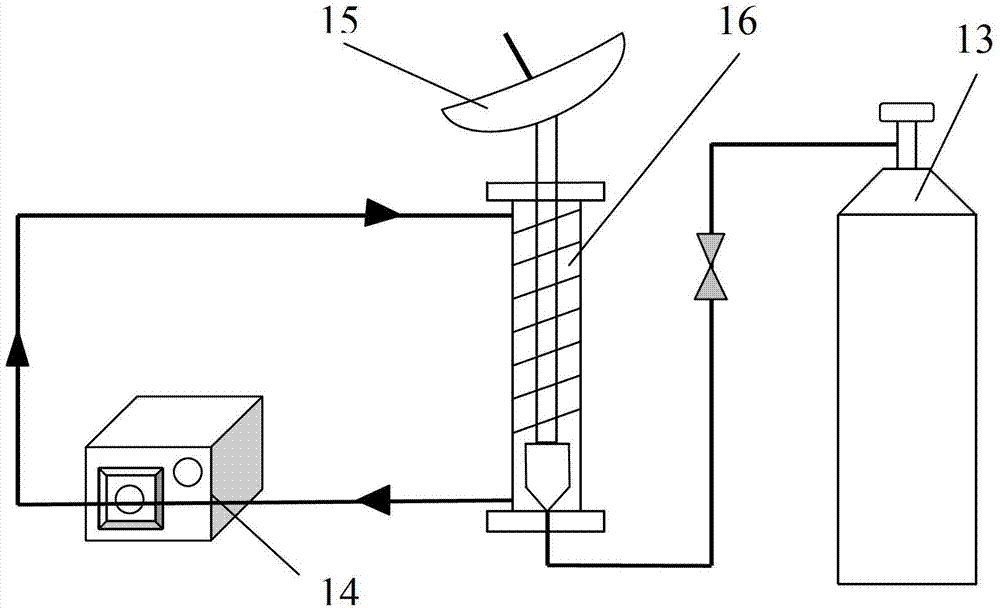

[0019] see figure 1 and figure 2 , the diffuse optical fiber photobioreactor inserted into the spiral bond is composed of an optical fiber core 1, a top cover 2, an outer tube 3, a spiral bond 4, an inner tube 5, a sand core funnel 7, a bottom cover 8 and a sealing plug 9. The outer tube 3, the top cover 2 and the bottom cover 8 are all provided with through holes, and the tube wall of the outer tube 3 is provided with a liquid inlet 10 and a liquid outlet 11; the top cover 2 is arranged on the top of the outer tube 3 , the bottom cover 8 is arranged on the bottom of the outer tube 3; the top of the inner tube 5 is provided with a step 6, and the step 6 is provided with an exhaust hole 17, and the inner tube 5 passes through the through hole of the top cover 2 and inserted into the through hole of the outer tube 3, and is limited by the step 6 arranged on the top of the inner tube 5; a spiral tie 4 is arranged between the outer tube 3 and the inner tube 5, and the spiral tie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com