Drill rod joint

A technology for drill pipe joints and female joints, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problem that the torsional strength and sealing performance cannot meet the requirements of the geological environment, the stress of the drill pipe joints cannot be well dispersed, and the threads are easy to Fatigue fracture and other problems, to achieve the effect of improving the salvage ability, reducing the chance of deposition in the joint, and improving the hydraulic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

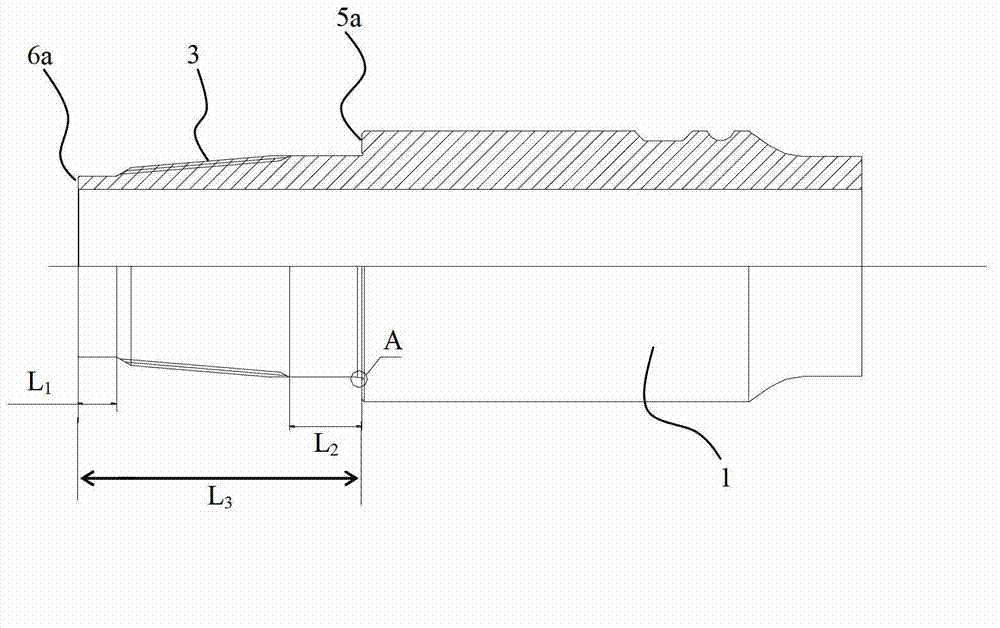

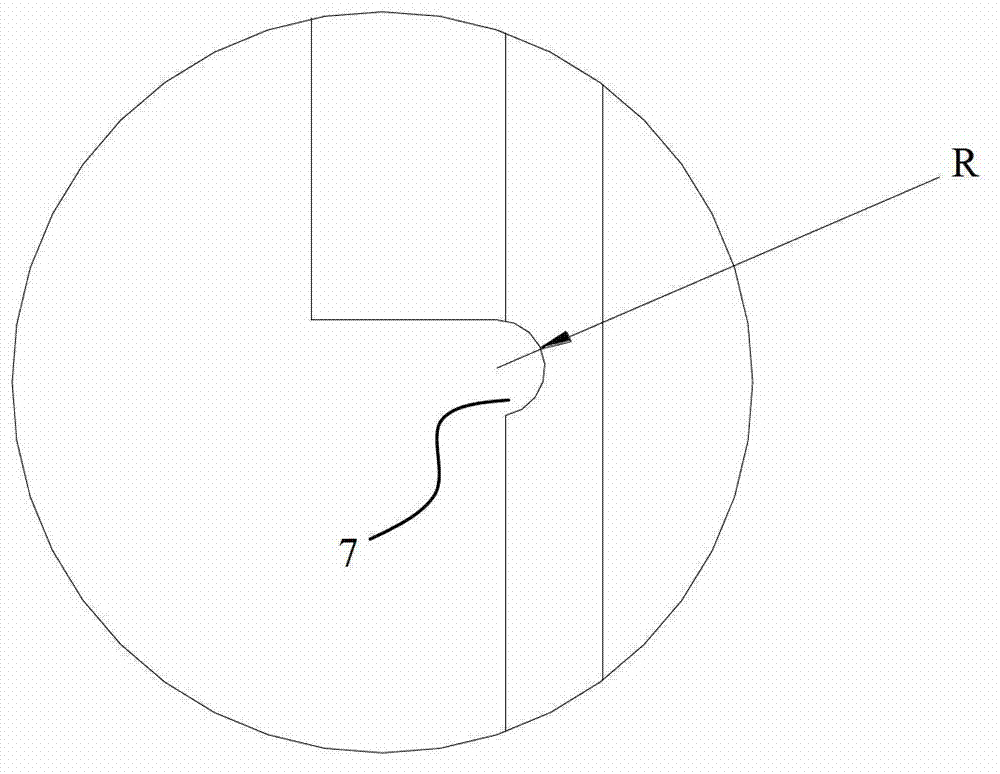

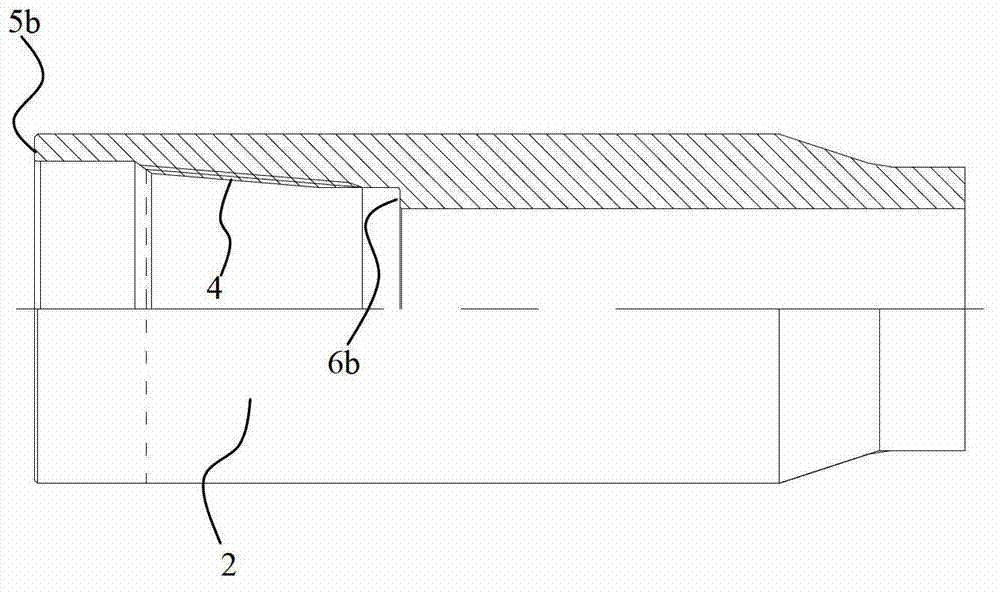

[0023] Such as Figures 1 to 4 As shown, the drill pipe joint of the present invention includes a male joint 1 and a female joint 2, and the male and female joints 1, 2 are connected to each other through the outer and female joint threads 3, 4; the two sides of the male joint thread 3 are respectively arranged There is a main shoulder 5a of a male joint and a secondary shoulder 6a of a male joint. The two sides of the female joint thread 4 are respectively provided with a main shoulder 5b of a female joint and a secondary shoulder 6b of a female joint. The main shoulder is used for sealing and Anti-torsion effect, the secondary shoulder plays an anti-torsion effect; the taper of the male and female joint threads 3 and 4 is 1:6. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com