Core three-dimensional multi-parameter measuring instrument based on visual observation of crack

A multi-parameter, measuring instrument technology, applied in the direction of measuring devices, scientific instruments, suspension and porous material analysis, etc., can solve the problems of inability to complete rock anisotropy, inability to complete rock physical parameters at the same time, single function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

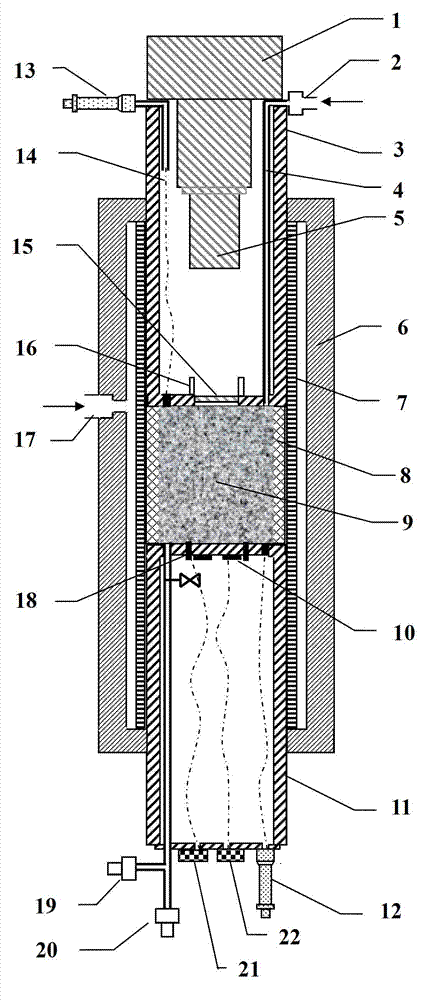

[0024] Example 1: Such as figure 1 As shown, the core holder includes a kettle body 6. The lower end of the kettle body 6 is equipped with a common lower plunger 11, and a rubber sleeve 8 is arranged above the common lower plunger. The upper end of the core 9 corresponds to the upper end of the square core 9 and the upper end of the rubber sleeve 8 with a visualization plunger 3 installed. In this embodiment, the visualization plunger 3 includes a camera 1 installed on the upper end of the visualization plunger cylindrical barrel and extending into the visualization plunger barrel. The camera 1 is equipped with a zoom lens 5, and the zoom lens 5 is There is a glass observation window 15 for observation on the lower end surface of the corresponding visualization plunger 3, and the two sides of the glass observation window 15 correspond to the inner surface of the bottom end of the visualization plunger cylinder with visible light sources 16 for supplying visible light. The outer...

Embodiment 2

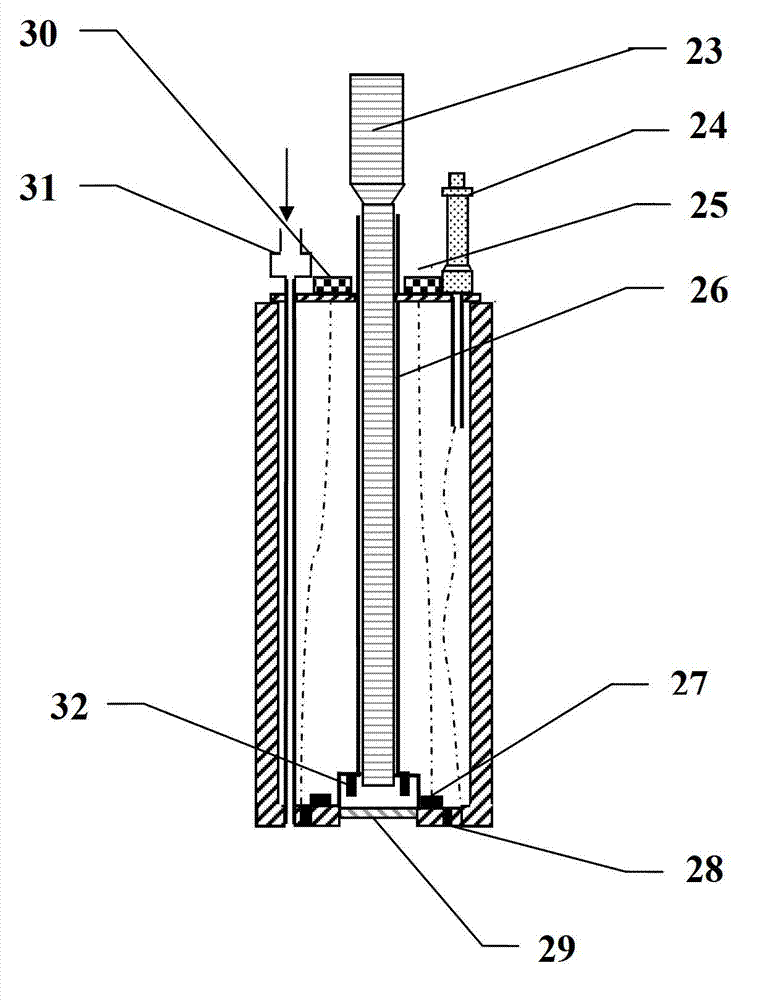

[0029] Example 2: figure 2 Shown is the schematic diagram of the electroacoustic plunger section, which is needed when measuring the electroacoustic parameters of the rock by the instrument figure 2 Electroacoustic plunger replacement shown in figure 1 The visualization plunger 3, the kettle body and the lower plunger part and figure 1 The same as shown in. In this embodiment, the electroacoustic plunger includes an electroacoustic plunger endoscope 23 for observing changes in the end face of the core, and the exterior of the electroacoustic plunger endoscope 23 is used to fix the position of the endoscope The hollow annular electroacoustic plunger connecting rod 26 is equipped with a visible light source 32 for providing visible light at the lower end of the electroacoustic plunger connecting rod. A glass observation window 29 is directly below the visible light source 32. The glass observation Outside the window 29 is an electrode ring 28 embedded in the bottom end surface o...

Embodiment 3

[0034] Example 3: image 3 Shown is a schematic diagram of the porosity and permeability plunger profile. The porosity and permeability plunger is used to measure the porosity and permeability parameters of the rock sample. image 3 Porosity plunger replacement shown in figure 1 In the visualization plunger, the rest remains unchanged. In this embodiment, there is an endoscope 33 in the middle of the porosity plunger for observing the change of the end face of the core, and outside the endoscope is a ring-shaped porosity plunger connecting rod 35 for fixing the endoscope. The lower end of the permeable plunger rod 35 is equipped with a visible light source 36 for providing light, and a transparent glass observation window 37 is installed directly below the visible light source 36 and the endoscope 33. The glass observation The window 37 is inlaid in the center of the lower end surface of the porosity plunger. The outer side of the endoscope 33 corresponds to the outer edge of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com