Standard capacitor installed by separated type coaxial structure

A standard capacitor and coaxial structure technology, applied in the direction of capacitors, tubular capacitors, fixed capacitor electrodes, etc., can solve problems affecting performance, capacitor voltage coefficient, temperature coefficient, pressure coefficient, and complicated installation, etc., to reduce the temperature coefficient and Effect of pressure coefficient, avoiding capacitance change, and reducing voltage coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples. Those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms are also within the scope of the claims listed in this application.

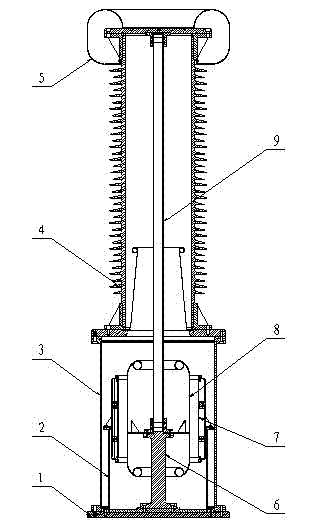

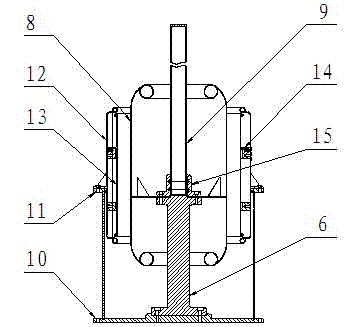

[0014] Marking description in the figure: 1-base plate, 2-electrode fixing platform, 3-housing assembly, 4-high voltage bushing, 5-voltage equalizing ring, 6-pillar insulator, 7-low voltage electrode and shielding assembly, 8-high voltage Electrode, 9-conducting rod, 10-bottom plate of electrode fixing platform, 11-flange of electrode fixing platform, 12-shielding part, 13-low voltage electrode, 14-insulating part, 15-spring contact finger seat.

[0015] figure 1 It is the overall structure diagram of the present invention, and the present invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com