Small-capacity epoxy resin poured dry type transformer

A dry-type transformer and epoxy resin technology, applied in the direction of transformer/inductor magnetic core, transformer/inductor parts, transformer/inductor coil/winding/connection, etc., can solve the problem of complex insulation process and insulation structure. Phase short circuit, single-phase grounding and other problems, to achieve the effect of improving safe use performance, improving electrical insulation strength, and increasing insulation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable the public to fully understand the technical essence and beneficial effects of the present invention, the applicant will describe in detail the specific implementation of the present invention below in conjunction with the accompanying drawings, but the applicant's description of the embodiments is not a limitation to the technical solution. Changes in the form of the inventive concept rather than in substance should be regarded as the protection scope of the present invention.

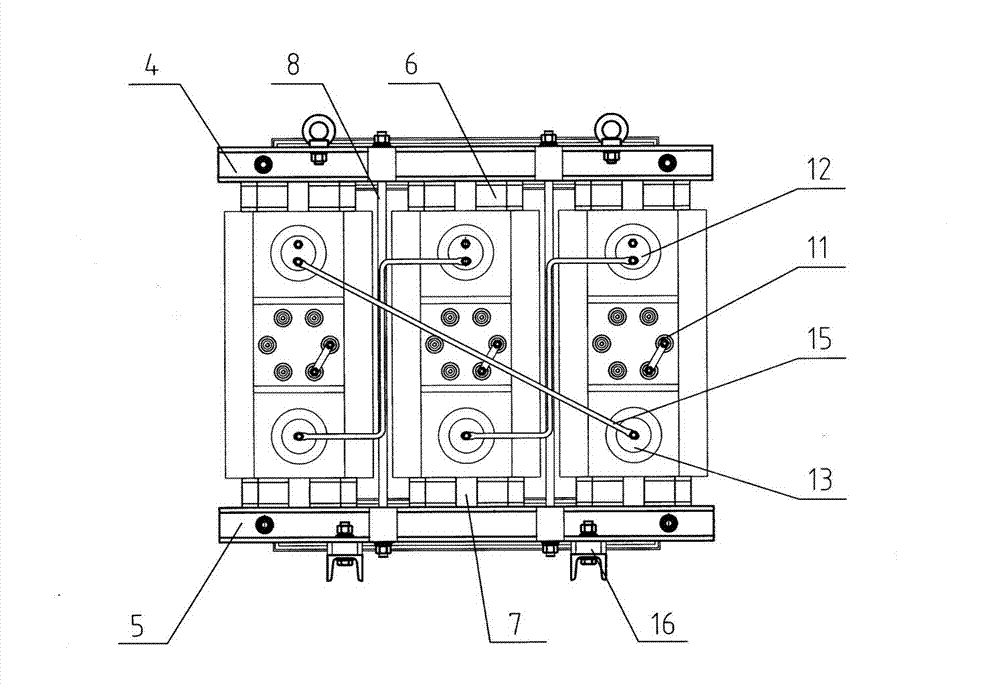

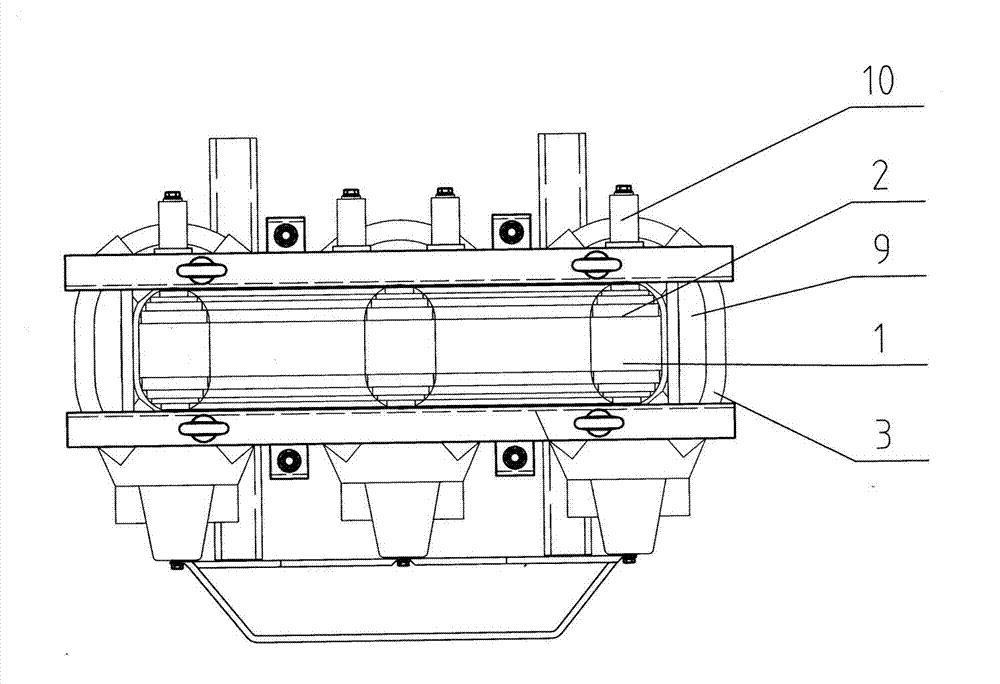

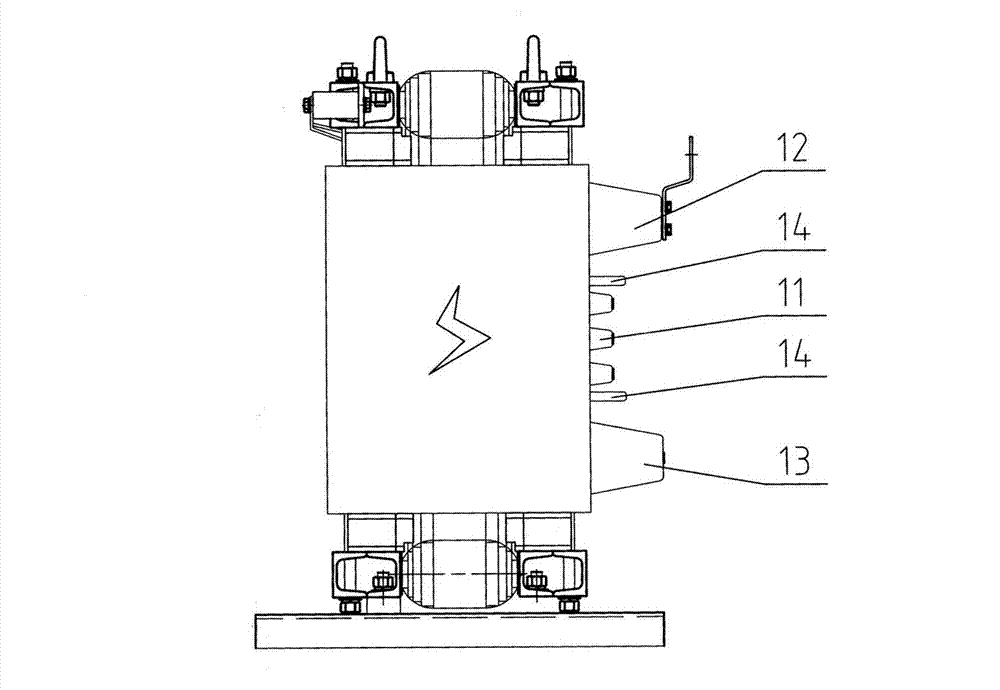

[0023] see figure 1 and combine figure 2 , image 3 and Figure 4 , a small-capacity epoxy resin cast dry-type transformer, including an iron core 1, a low-voltage coil 2 wound on the iron core 1, a high-voltage coil 3 wound on the outer periphery of the low-voltage coil 2, an upper clamp 4, and a lower clamp 5. Upper block 6, lower block 7 and pull screw 8. The iron core 1 is formed by stacking cold-rolled grain-oriented silicon steel sheets in a 45° full oblique joint....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com