Conductor overlap welding end socket

A technology of lap welding and wire, which is applied in the direction of connection, coil manufacturing, contact manufacturing, etc., can solve the problems of partial discharge at the wire welding place, achieve stable welding quality, improve short-circuit resistance, and reduce partial discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

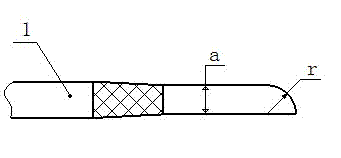

[0011] figure 1 Shown is a schematic front view of the structure of the present invention.

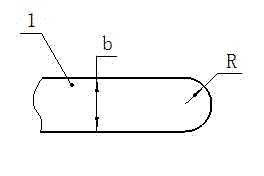

[0012] figure 2 Shown is a schematic top view of the structure of the present invention.

[0013] The present invention includes a wire 1, and the specification of the wire is a×b, wherein a is the thickness of the wire; b is the width of the wire.

[0014] The thickness direction of the wire end point is a single arc with radius r, and the width direction is a double arc with radius R, where r=a, R=b / 2.

[0015] The present invention is realized through the following steps: wire welding end stripping insulation: 40 ~ 60mm; wire end repairing file r=a one-way arc (such as figure 1 as shown); use a special tool to cut the end of the wire into R=b / 2 (such as figure 2 shown).

[0016] Adopt welding technique of the present invention:

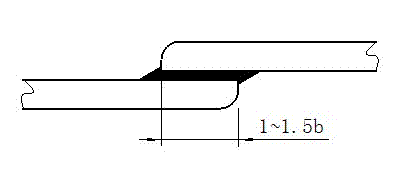

[0017] Wire lap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com