Reflecting plate based on frequency selection surface units

A frequency selective surface, frequency selective technology, applied in electrical components, antennas and other directions, can solve the problems of inability to achieve multi-angle antenna radar cross section reduction, large size, inability to use antennas, etc., achieve good angular stability, extend the total length, The effect of increasing the effective arm length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

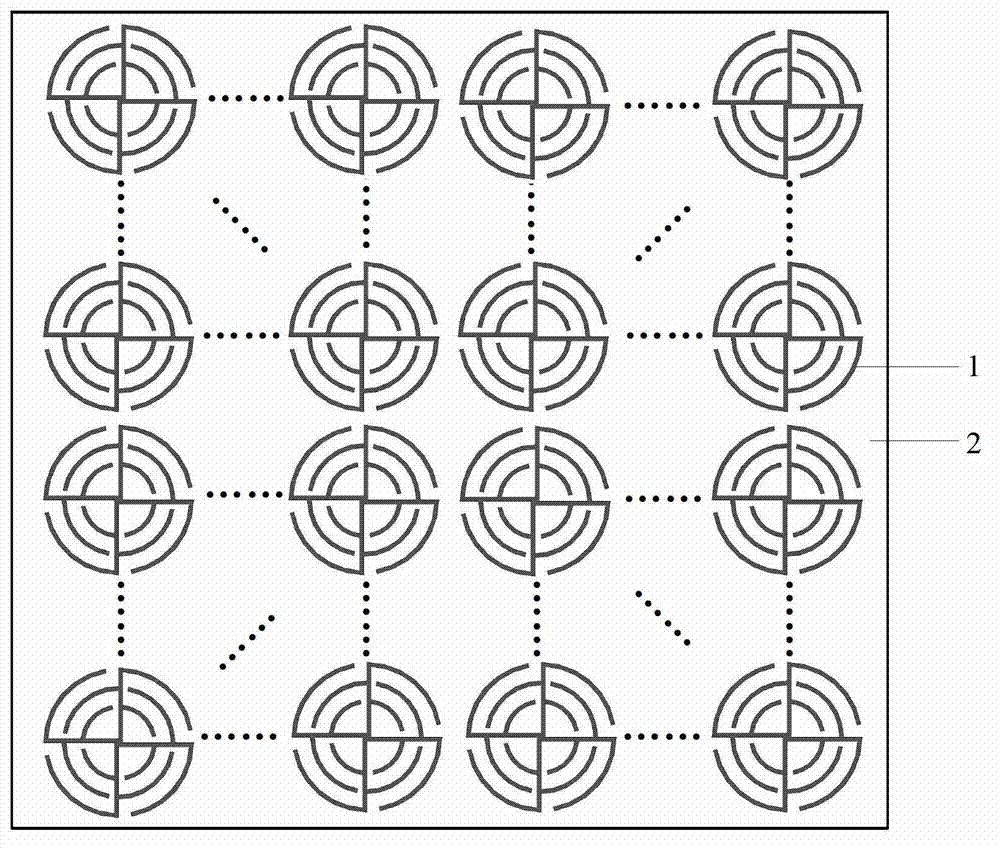

[0032] Embodiment 1: the resonant frequency that is made up of 240 frequency selective surface units is the reflecting plate of 3.8GHz

[0033] The substrate of the frequency selective surface reflector is FR4 dielectric board with a length of 264mm, a width of 110mm, a thickness of 1.6mm, and a dielectric constant of 4.4.

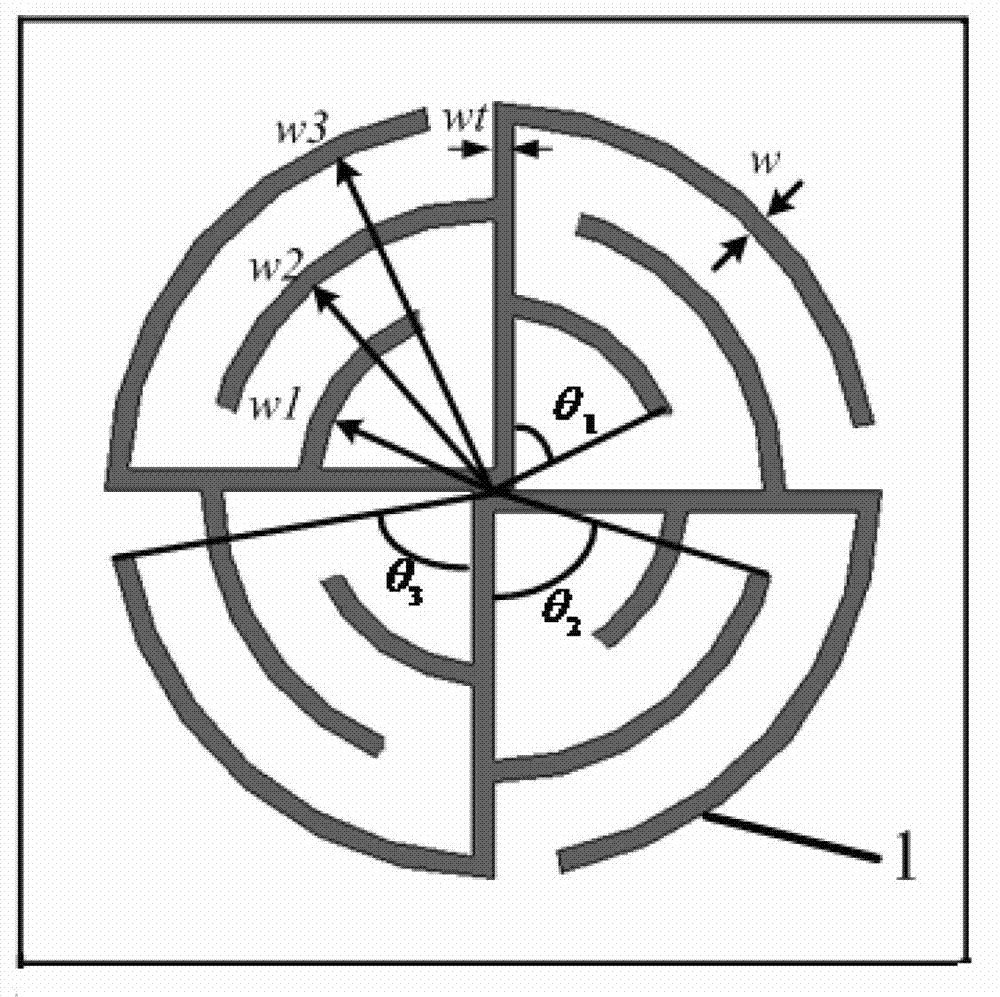

[0034] The length w of the rectangular trunk of the patch l=4.5mm, width w t =0.25mm, three arc branches are alternately distributed on the rectangular trunk, the width of the arc branches is w=0.2mm, and the radii of the three arc branches are respectively w from the inside to the outside 1 =2.28mm, w 2 =3.39mm, w 3 =4.5mm, the coverage angles are θ 1 = θ 2 = θ 3 =80°.

[0035] On the surface of a 264mm×110mm rectangular substrate, the grid is evenly divided according to a square with a side length of 11mm. The center of the square grid is the center of the frequency selective surface unit. The 240 frequency selective surface units are uniformly ar...

Embodiment 2

[0036] Embodiment 2: the resonant frequency that is made up of 120 frequency selective surface units is the reflecting plate of 3.9GHz

[0037] The substrate of the frequency selective surface reflector is an FR4 dielectric board with a length of 264 mm, a width of 65 mm, a thickness of 1.6 mm, and a dielectric constant of 4.4.

[0038] The length w of the rectangular trunk of the patch l =4.4mm, width w t =0.25mm, two arc branches are alternately distributed on the rectangular trunk, the width of the arc branches is w=0.19mm, and the radii of the two arc branches are respectively w from the inside to the outside 1 =3.39mm, w 2 =4.6mm, the coverage angles are θ 1 =75°, θ 2 =80°.

[0039] On the surface of a 264mm×65mm rectangular substrate, the grid is evenly divided into rectangles with a side length of 11mm and a width of 13mm. The center of the rectangular grid is the center of the frequency selective surface unit. The 120 frequency selective surface units are arranged...

Embodiment 3

[0040] Embodiment 3: the resonant frequency that is made up of 100 frequency selective surface units is the reflector of 4GHz

[0041] The base plate of the frequency selective surface reflector is an FR4 dielectric board with a length of 120 mm, a width of 120 mm, a thickness of 1.6 mm, and a dielectric constant of 4.4.

[0042] The length w of the rectangular trunk of the patch l =4.3mm, width w t =0.24mm, two arc branches are alternately distributed on the rectangular trunk, the width of the arc branches is w=0.2mm, and the radii of the two arc branches are respectively w from the inside to the outside 1 =3.37mm, w 2 =4.5mm, the coverage angles are θ 1 =75°, θ 2 =80°.

[0043] On the surface of a 120mm×120mm square substrate, the grid is evenly divided according to a square with a side length of 12mm. The center of the square grid is the center of the frequency selective surface unit. The 100 frequency selective surface units are uniformly arranged in a rectangular sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com