Reactive compensation discharge device

A discharge device and compensation capacitor technology, applied in reactive power compensation, circuit devices, reactive power adjustment/elimination/compensation, etc., can solve problems that are difficult to implement, have little effect on re-ignition rate, and are difficult to apply in practice. The effect of eliminating reignition, omitting aging experiments, and improving reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

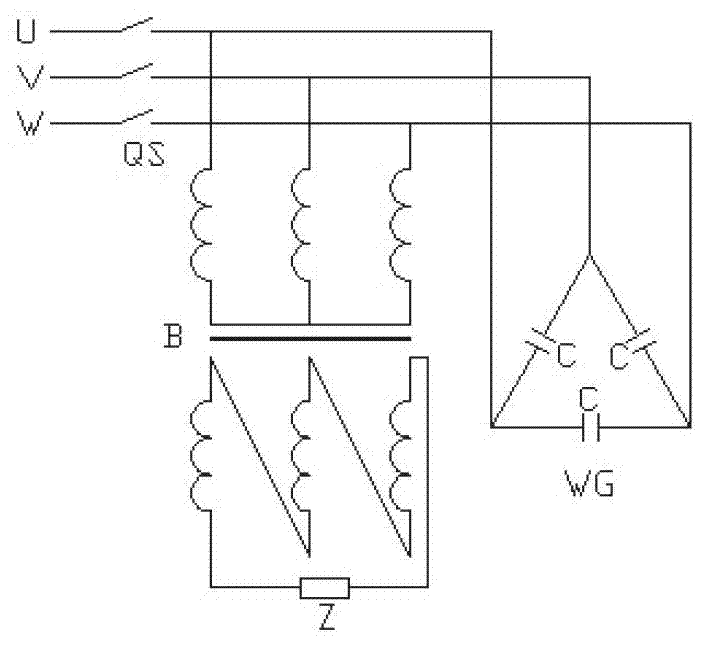

[0026] Such as Figure 4 In figure a, the 35kV reactive power compensation device is 12000kVar, the capacitor bank △ connection mode, the reactive power compensation discharge device transformer primary winding △ connection mode, the reactive power compensation discharge device transformer capacity is 6kVA, and the reactive power compensation discharge device transformer ratio is 150 : 1. The impedance of the secondary winding of the secondary winding of the reactive power compensation discharge device connected in parallel with the delta is a resistance, and its value is 1 ohm.

Embodiment 2

[0028] Such as Figure 4 In figure d, the 35kV reactive power compensation device is 9000kVar, the capacitor bank is Y connection mode, the primary winding of the transformer of the reactive power compensation discharge device is Y connection mode, the transformer capacity of the reactive power compensation discharge device is 3kVA, and the transformer ratio of the reactive power compensation discharge device is 90:1, the impedance of the secondary winding of the reactive power compensation discharge device connected in triangular parallel connection is resistance, and its value is 1.5 ohms.

Embodiment 3

[0030] Such as Figure 4 In the diagram e, the 10kV reactive power compensation device is 3000kVar, the capacitor bank is Y connection, the primary winding of the transformer of the reactive power compensation discharge device is Y connection, the neutral point of the transformer primary winding of the reactive power compensation discharge device is connected to the neutral point of the reactive power compensation capacitor bank The point-to-phase connection, the transformer capacity of the reactive power compensation discharge device is 3kVA, the transformer transformation ratio of the reactive power compensation discharge device transformer is 25:1, and the impedance of the secondary winding of the reactive power compensation discharge device connected in triangular parallel connection is resistance, and its value is 0.5 ohms .

[0031] Principle analysis:

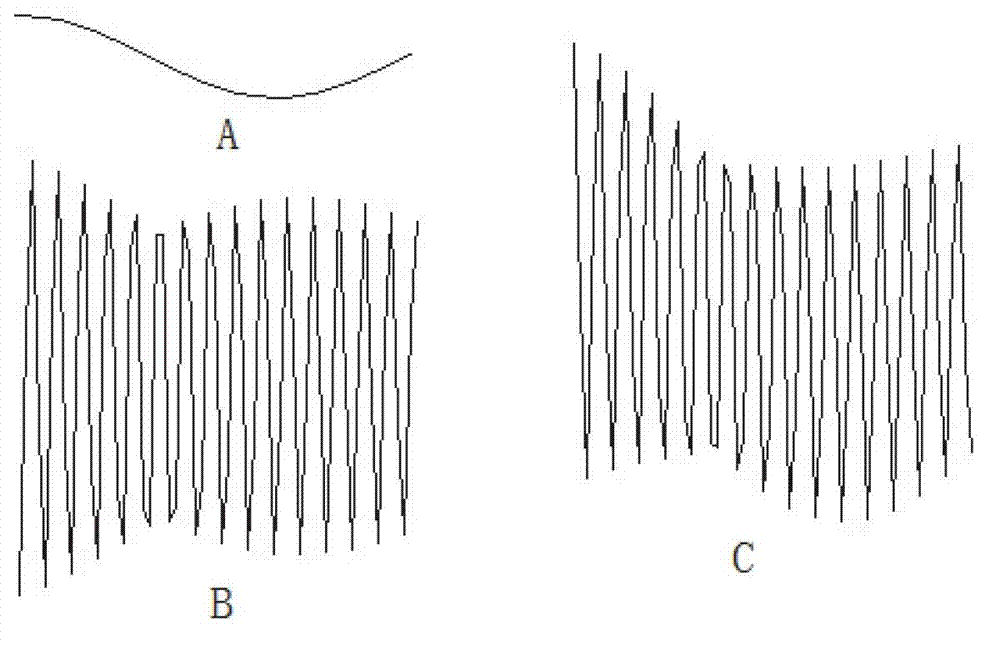

[0032] The charge stored in the reactive power compensation capacitor is the real culprit of the switch reignition

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com