Method for flue gas desulfurization and byproduct polymeric ferric sulfate production by using steel pickling waste liquor

A technology of iron and steel pickling waste liquid and polymeric ferric sulfate, which is applied in the direction of ferric sulfate, microbial-based methods, separation methods, etc., can solve the problems of low quality and basicity of polymeric ferric sulfate, large amount of catalyst, and long oxidation time , to achieve the effect of low cost, increased added value and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

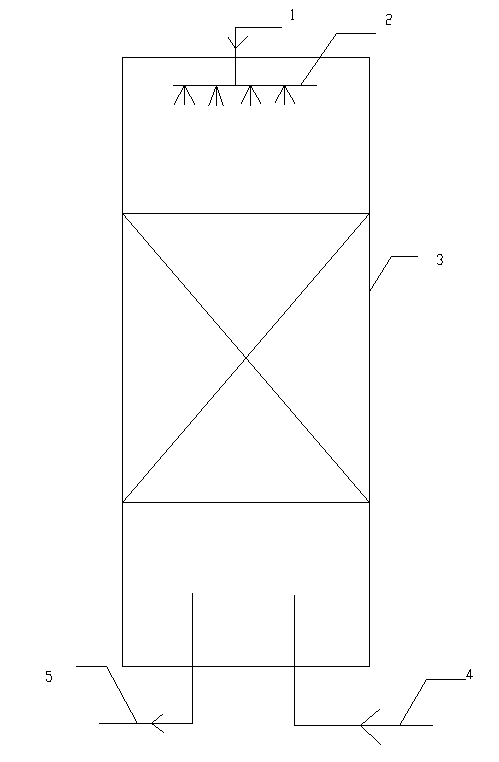

[0026] Hanging film of biological packed tower

[0027] Rejuvenation of Thiobacillus ferrooxidans. Thiobacillus ferrooxidans was inoculated with 9k culture medium at an optimal inoculum size of 10% to 30%, adjusted to a pH of 2.0 to 2.5, and cultured in a constant temperature shaking box at a temperature of 20 to 30°C. Repeated inoculation and culture until Thiobacillus ferrooxidans reached the best activity state.

[0028]The packing tower hangs the film. Add the above cultured Thiobacillus ferrooxidans into the activated sludge from the secondary sedimentation tank, and after 7-15 days of cultivation and domestication, observe the microbial state with a microscope. A large number of bellworms, branchworms, and a small amount of worms appeared in the sludge. For rotifers, add the amount of sludge concentration of 0.5~5g / L into the biological packing tower. After standing still for 8 hours, ventilate and aerate for 12~36 hours, and start to feed water continuously. The amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap