Catalyst for chemical enhancement of ultrathin optical glass panel, and applications of catalyst

A technology of optical glass and catalyst, which is applied in physical/chemical process catalysts, glass tempering, glass manufacturing equipment, etc., and can solve problems such as long time required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

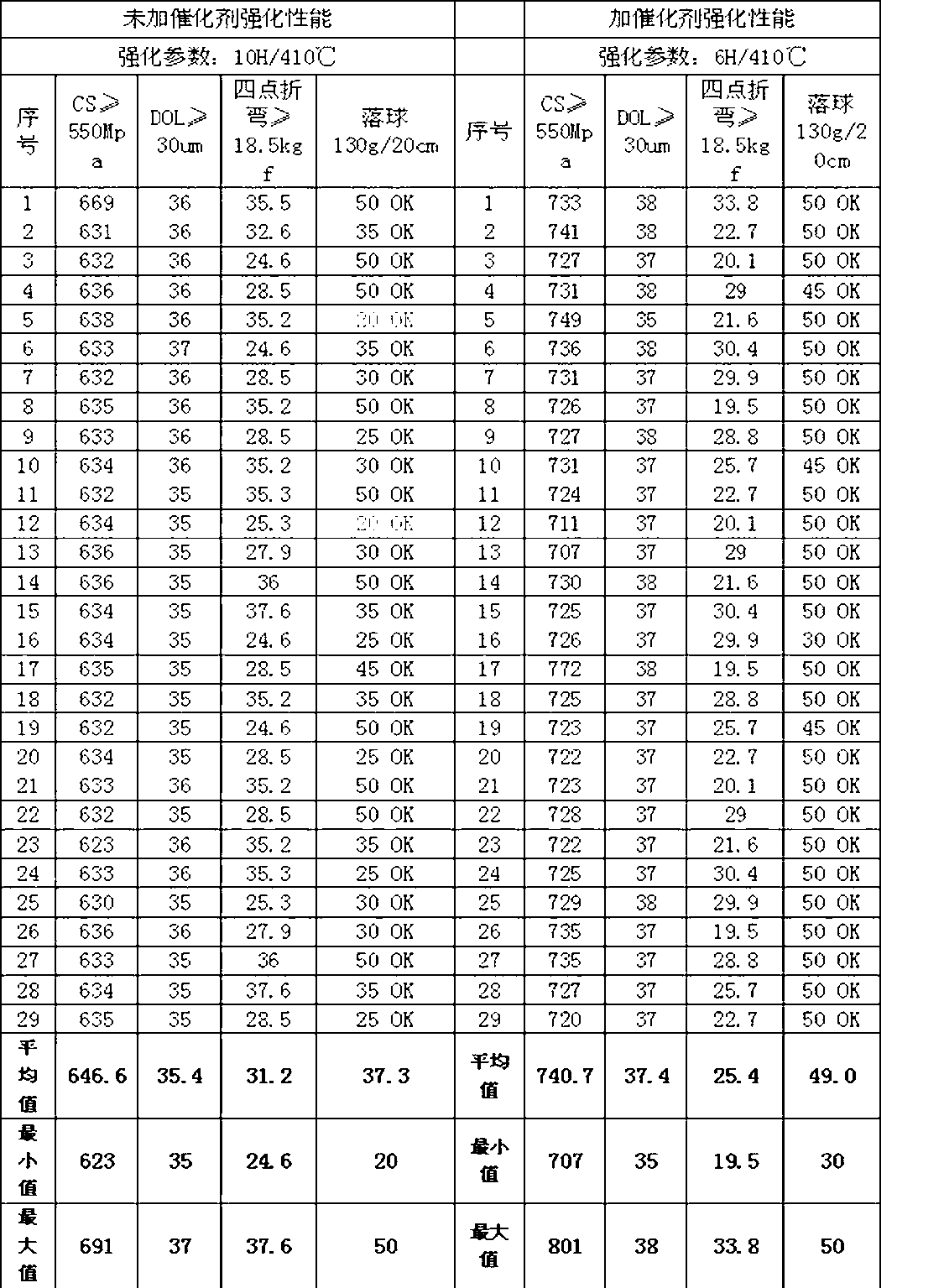

Examples

Embodiment 1

[0025] The catalyst for chemical strengthening of ultra-thin optical glass panels is made by mixing raw materials according to the following mass percentages: potassium carbonate 25%, potassium chloride 25%, sodium chloride 15%, aluminum oxide 25%, diatomite 10% %.

Embodiment 2

[0027] The catalyst for chemical strengthening of ultra-thin optical glass panels is made by mixing raw materials according to the following mass percentages: potassium carbonate 40%, potassium chloride 20%, sodium chloride 5%, aluminum oxide 20%, diatomite 15% %.

Embodiment 3

[0029] The catalyst for chemical strengthening of ultra-thin optical glass panels is made by mixing raw materials according to the following mass percentages: 50% potassium carbonate, 15% potassium chloride, 10% sodium chloride, 15% aluminum oxide, and 10% diatomaceous earth %.

[0030] The application of the catalyst in the chemical strengthening of ultra-thin optical glass panels is specifically as follows:

[0031] (1) Production of molten salt:

[0032] A. For preparation, wipe the molten salt furnace clean, raise the temperature of the furnace to 150°C, and keep the temperature constant for 30 minutes;

[0033] B. After drying in the molten salt furnace, start to add potassium nitrate, and after it is completely melted, settle at constant temperature for more than 12 hours;

[0034] C, after constant temperature finishes, add catalyst by the weight ratio of potassium nitrate, make strengthened molten salt;

[0035] (2) Strengthening steps:

[0036] Step a. Preheat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com