End face polishing and beveling machine of optical element

A technology of optical components and chamfering machines, applied to machine tools, grinding/polishing equipment, grinding machines, etc. suitable for grinding the edge of workpieces, it can solve the problems of not being able to polish at the same time, achieve good operability, improve efficiency and precision , highly controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

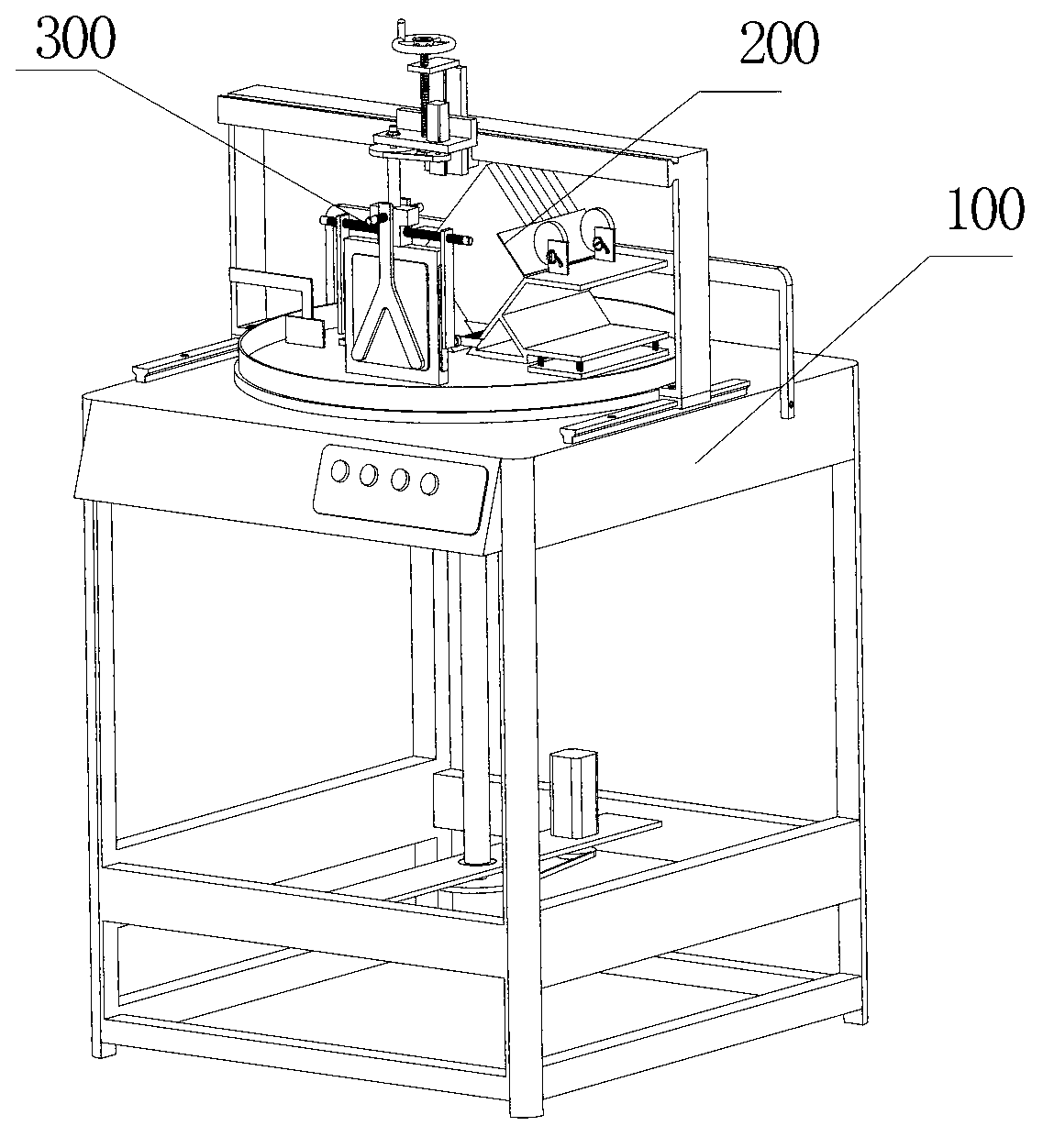

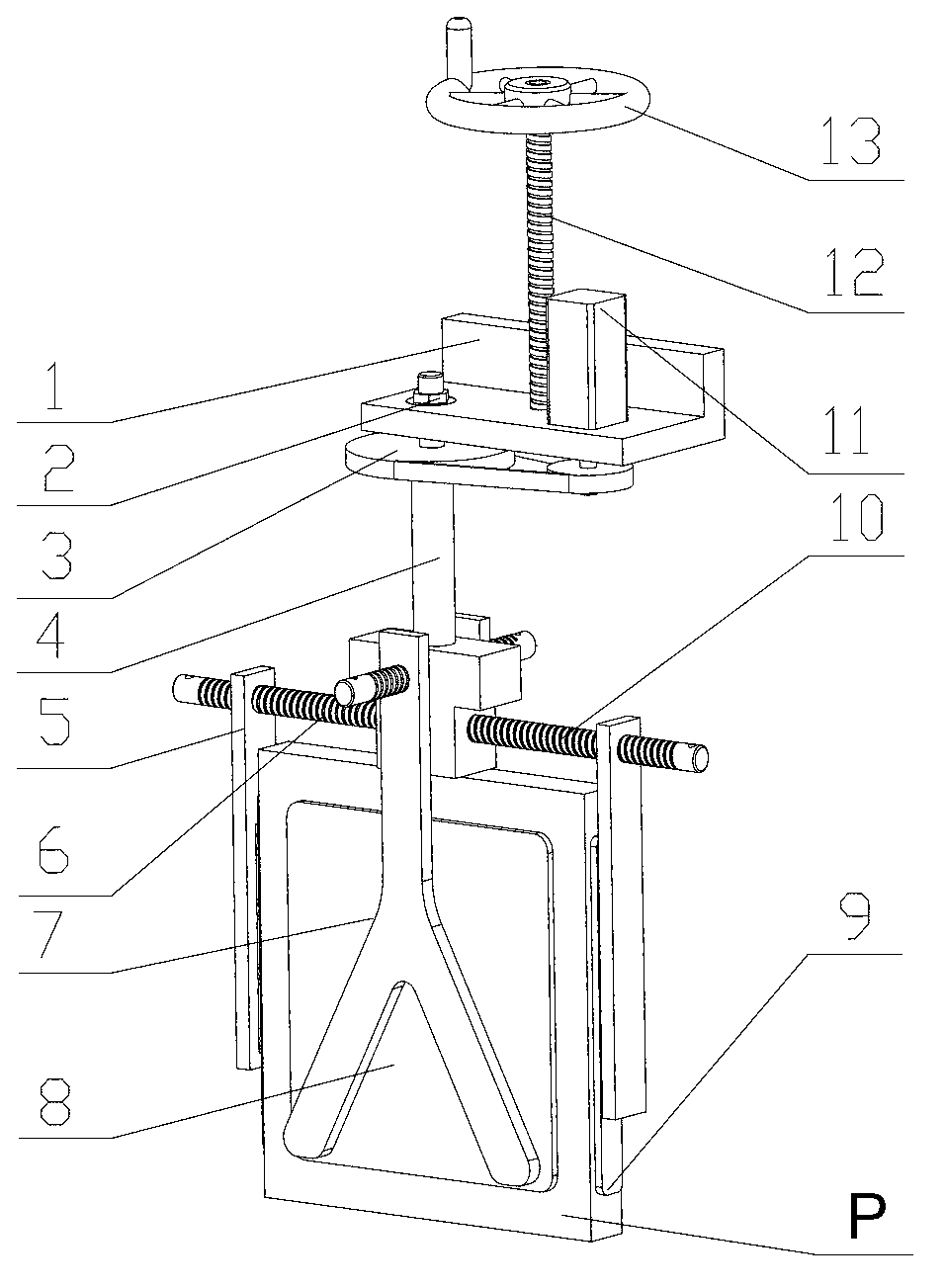

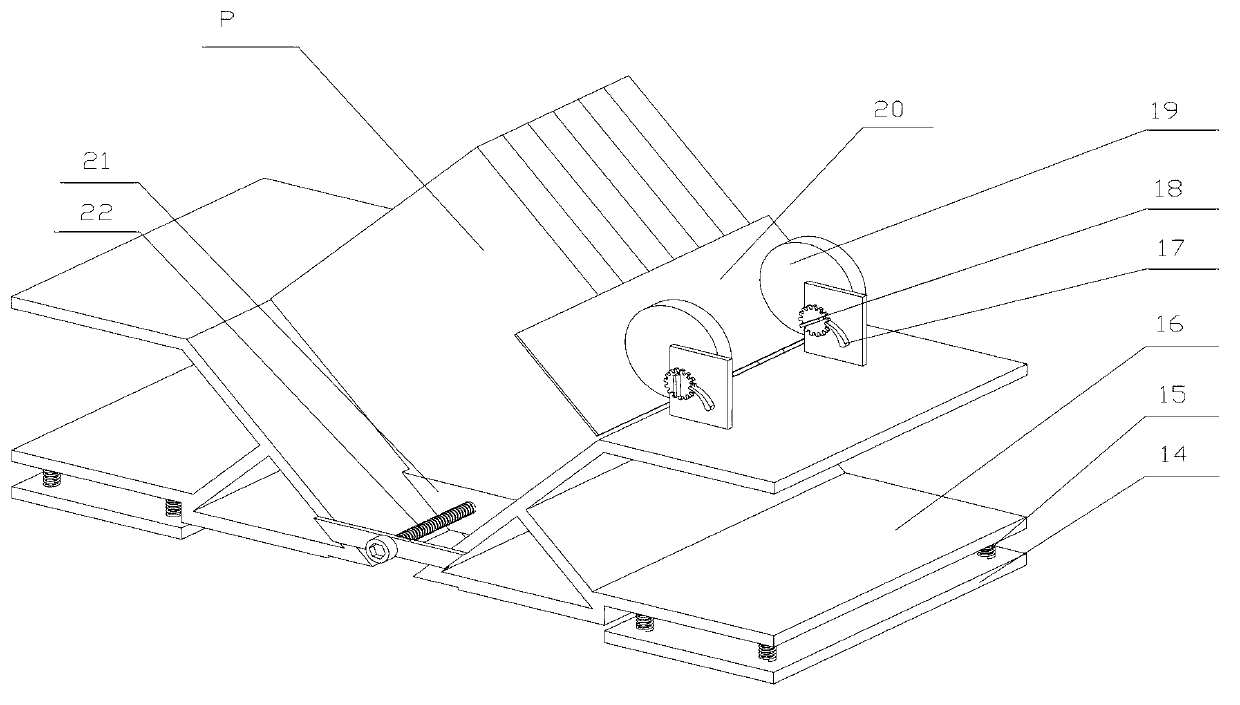

[0028] see figure 1 , the embodiment of the present invention consists of three major parts, namely the main body of the machine tool 100 , the polishing device 200 and the beveling device 300 .

[0029] see Figure 5 The main body of the machine tool is provided with a frame seat 23, a guide rail 24, a limiting arm 25, a gantry arm 26, a gantry arm slider 27, a grinding disc 28, a guide rail slider 29, a deflector 30, a current limiting ring 31, an operation panel 32, a motor 33 and belt wheel pair 34. Guide rail 24, limiting arm 25 are fixed on the frame seat 23 by screws, guide rail slider 29 and guide rail 24 form guide rail pair, gantry arm 26 is fixed on the guide rail slider 29, gantry arm slider 27 and gantry arm 26 form guide rail pair. The pulley pair 34 is connected with the grinding disc 28 and the motor 33 . The restrictor ring 31 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com