Circular-truncated-cone injection bonding machine

A bonding machine and glue injection technology, applied in coating and other directions, can solve the problems of cumbersome machine structure, low production efficiency and high production cost, and achieve the effects of novel design, improved efficiency, simple and lightweight structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

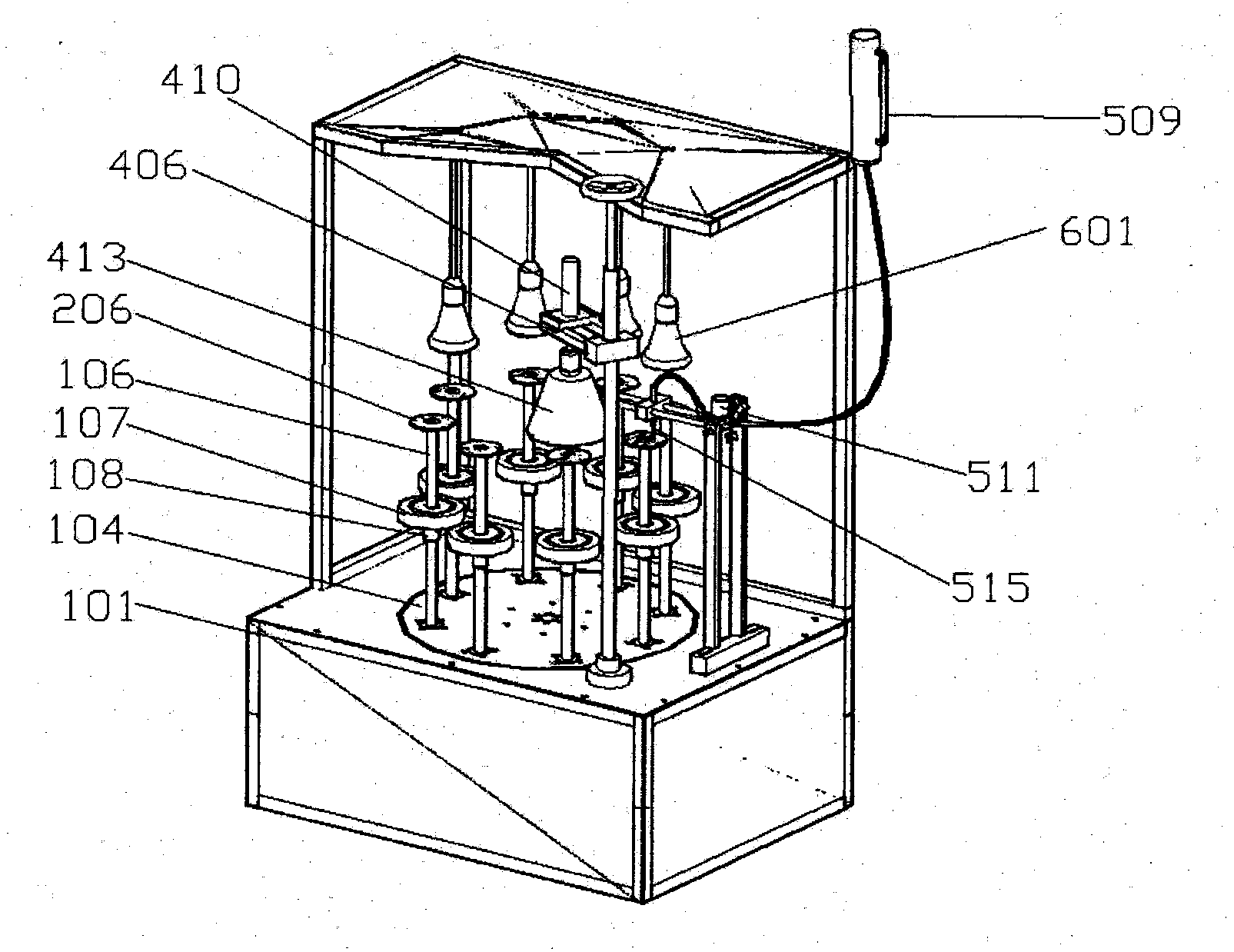

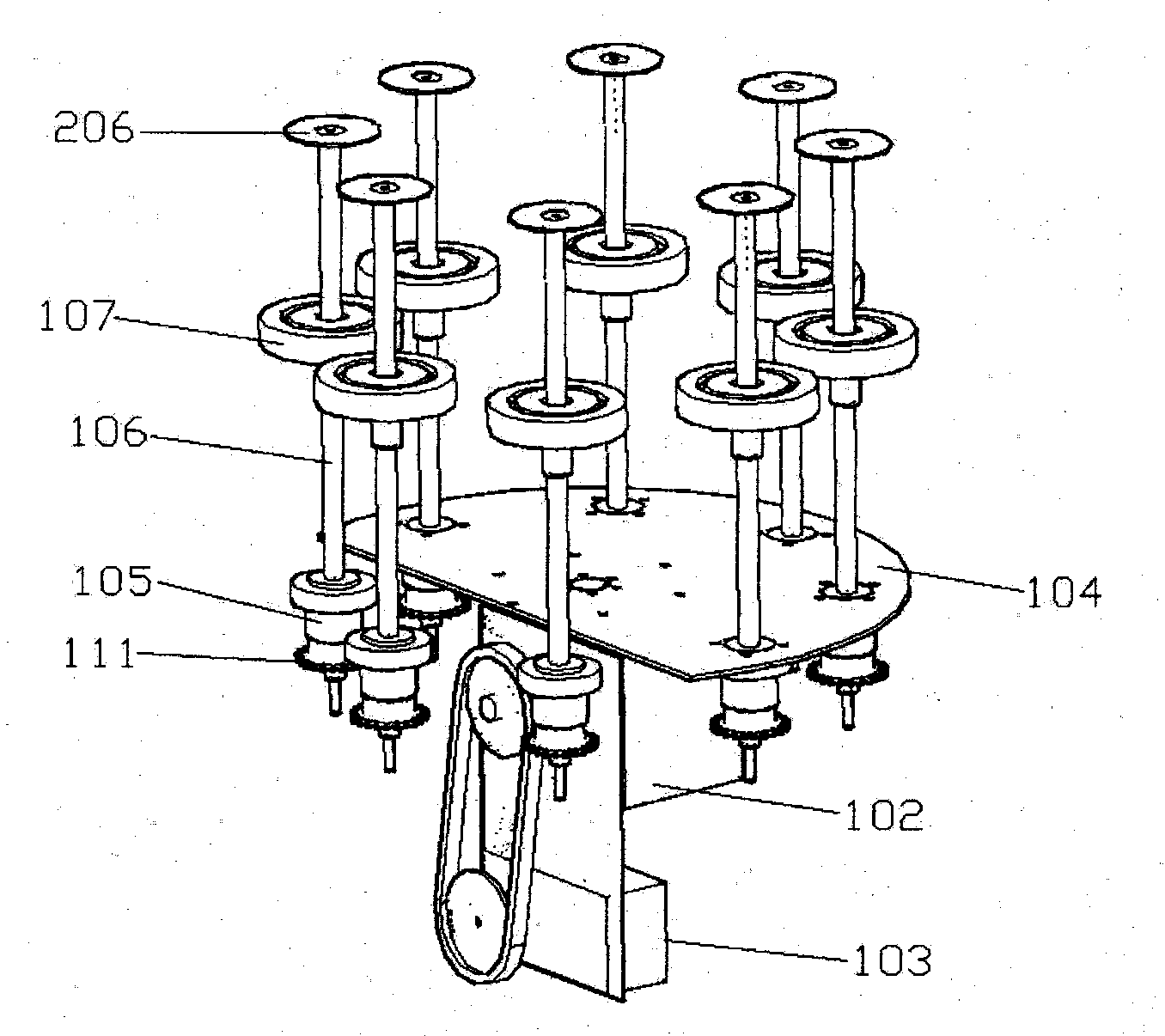

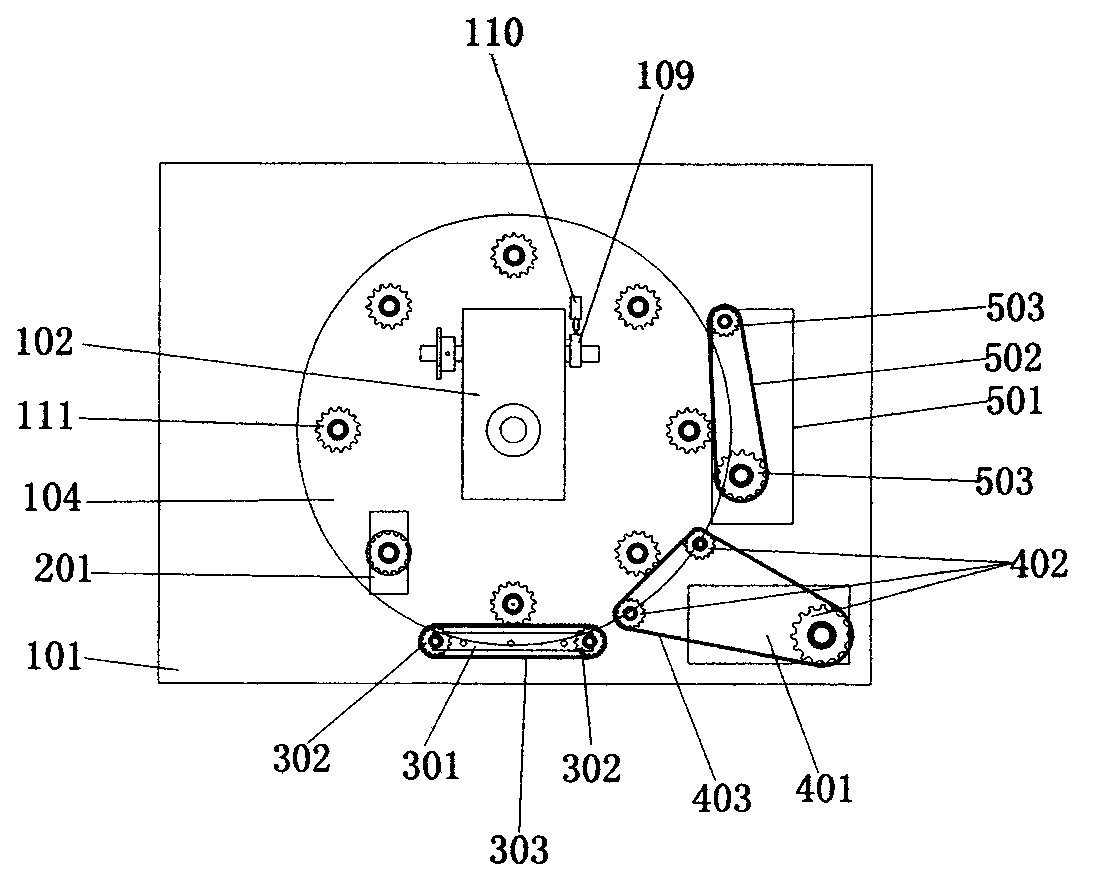

[0031] according to Figure 1-Figure 8 As shown, a round table type glue injection and bonding machine disclosed in the present invention is used to make cylindrical packaging products. The injection bonding machine includes a base 101, which is horizontally installed on the base 101 through a rotator 102 The round platen 104 is vertically mounted on the round platen 104 through eight sets of bearing seats 105 with eight mold shafts 106. The mold shaft 106 is a hollow tubular optical shaft. The mold is sleeved on the mold shaft 106 through the mold fastening sleeve 108 107. An ejection and ejection device is inserted into the hollow of each mold shaft 106. The upper end of the ejection and ejection device magnetically attracts a circular discus mold 206. A driven wheel 111 is installed on the lower end of each mold shaft 106. The mold shaft 106 can rotate independently, the round table plate 104 can drive the eight mold shafts 106 to make a revolution. The rotary drive assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com