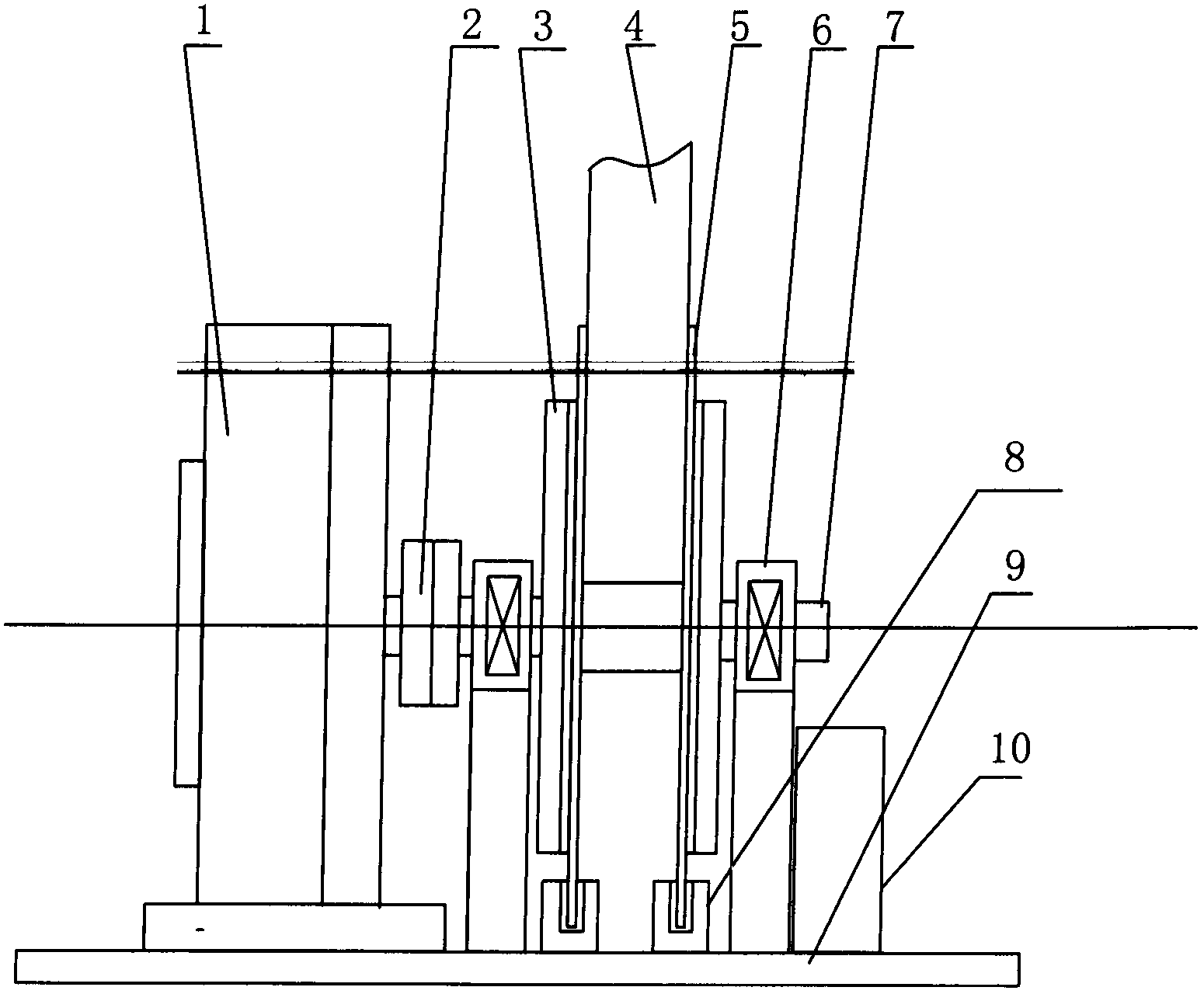

Two-way driving winding speedup type ship-borne aircraft catapult

A two-way drive, carrier-based aircraft technology, applied in the direction of launch/drag transmission, can solve the problems of high power consumption, unreliable stability, unusable single-engine fighters, etc., and achieve the effect of increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

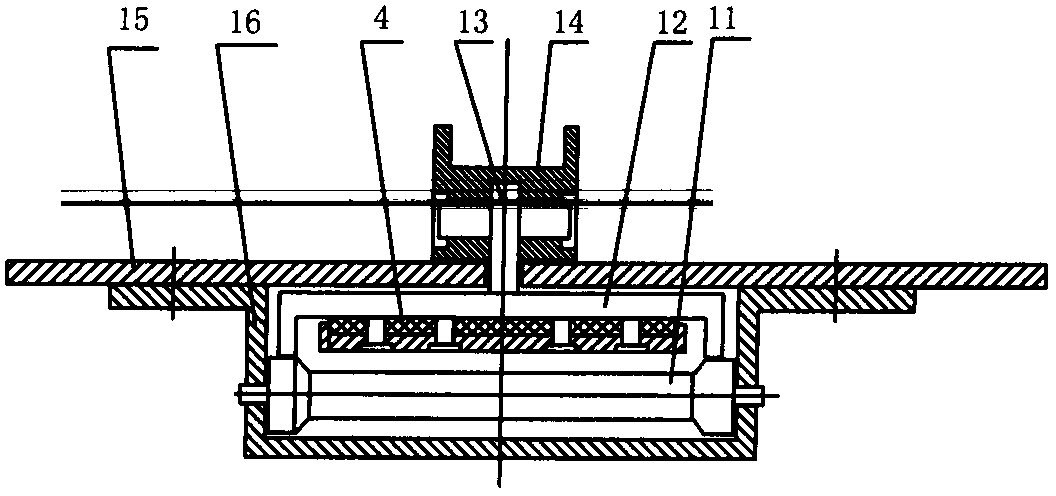

Embodiment

[0049] The design steps are as follows:

[0050] The carrier-based aircraft must obtain 30m / s on a 100-meter runway 2 Acceleration can take off, the aircraft takeoff speed and acceleration movement time calculation formula is as follows:

[0051] V=√(2aL)=√(200×30)≈77.46m / s (1)

[0052] t=√(2L / a)=√(200 / 30)≈2.58s (2)

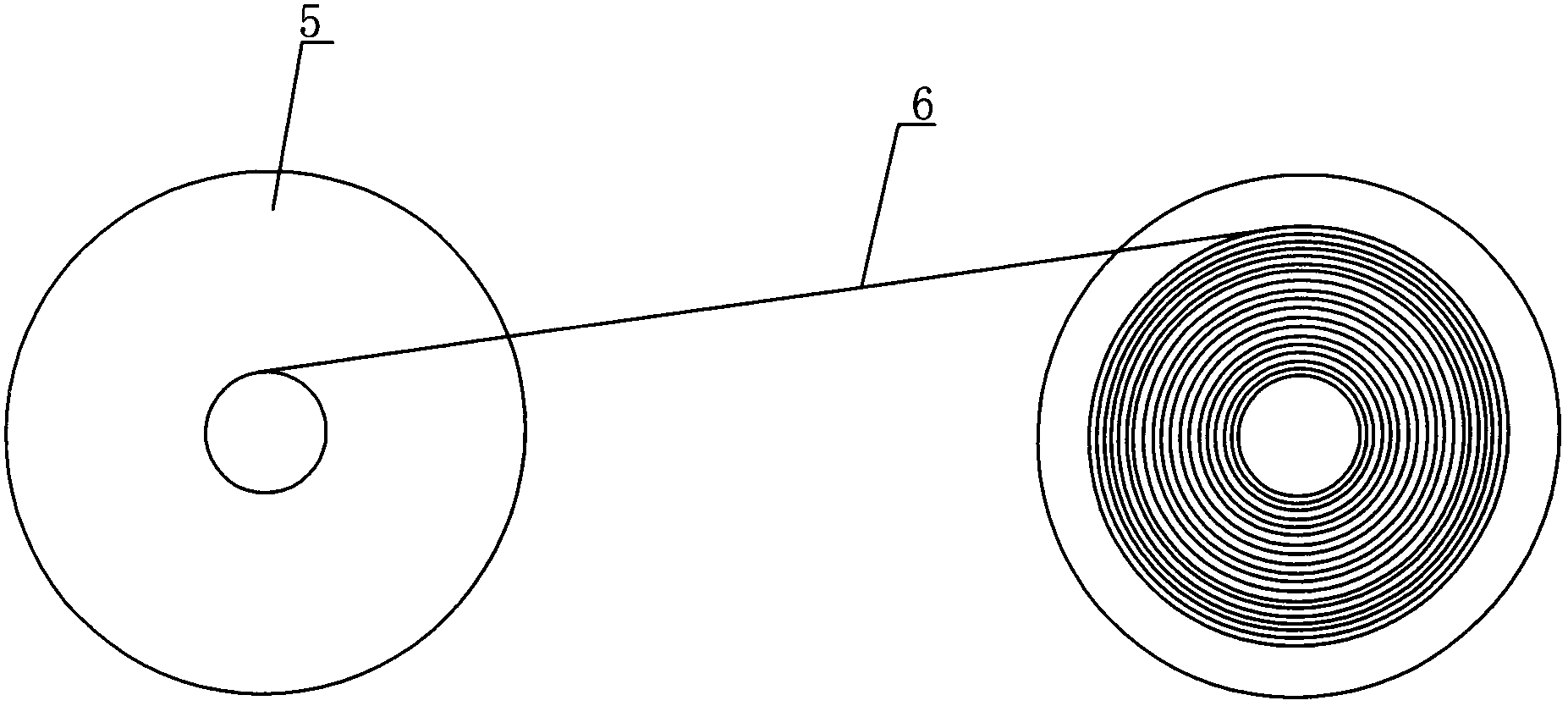

[0053] The length of the traction belt = the length of the runway, L = the sum of the lengths of the traction belts wound on the winch, the length of the traction belt

[0054] L = (L1 + L2 + ... LN) = 100 meters = the length of the ejection runway (3)

[0055] The formula for calculating the length of each layer of the traction belt of the winch: Li=3.14(D+2dn) (4)

[0056] D is the diameter of the winch shaft,

[0057] d = thickness of traction belt;

[0058] n = number of layers of traction belt

[0059] L=100=3.14[(D+2d1)+(D+2d2)+(D+2d3)+...(D+2dn)] (5)

[0060] The length of the known ejection track=the length of the traction belt=100 meters, ignore ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com