Anhydrous press-in slurry used for blast furnace

A technology without water pressure and mud, which is applied in the field of inorganic non-metallic refractory materials, can solve the problems of long maintenance cycle maintenance times, frequent maintenance, affecting efficiency, etc., and achieve the effect of reducing maintenance frequency, shortening maintenance time and improving thermal conductivity

Inactive Publication Date: 2013-02-06

TONGDA REFRACTORY TECH CO LTD +1

View PDF2 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to improve the service life of the blast furnace, improve the safety factor of the blast furnace, and avoid accidents, it is necessary to maintain the blast furnace regularly, and the excessively long maintenance cycle or too frequent maintenance times will affect the stable operation of the blast furnace, which is not conducive to the smooth production of the blast furnace Reach production

The traditional maintenance method needs to stop the furnace. After cooling the furnace, use the water system press-in material to fill the damaged part. Since the water-system press-in material needs to be baked for a long time, the efficiency is affected. At the same time, it shrinks greatly at high temperature and cannot form a whole. Generally, resulting in frequent maintenance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

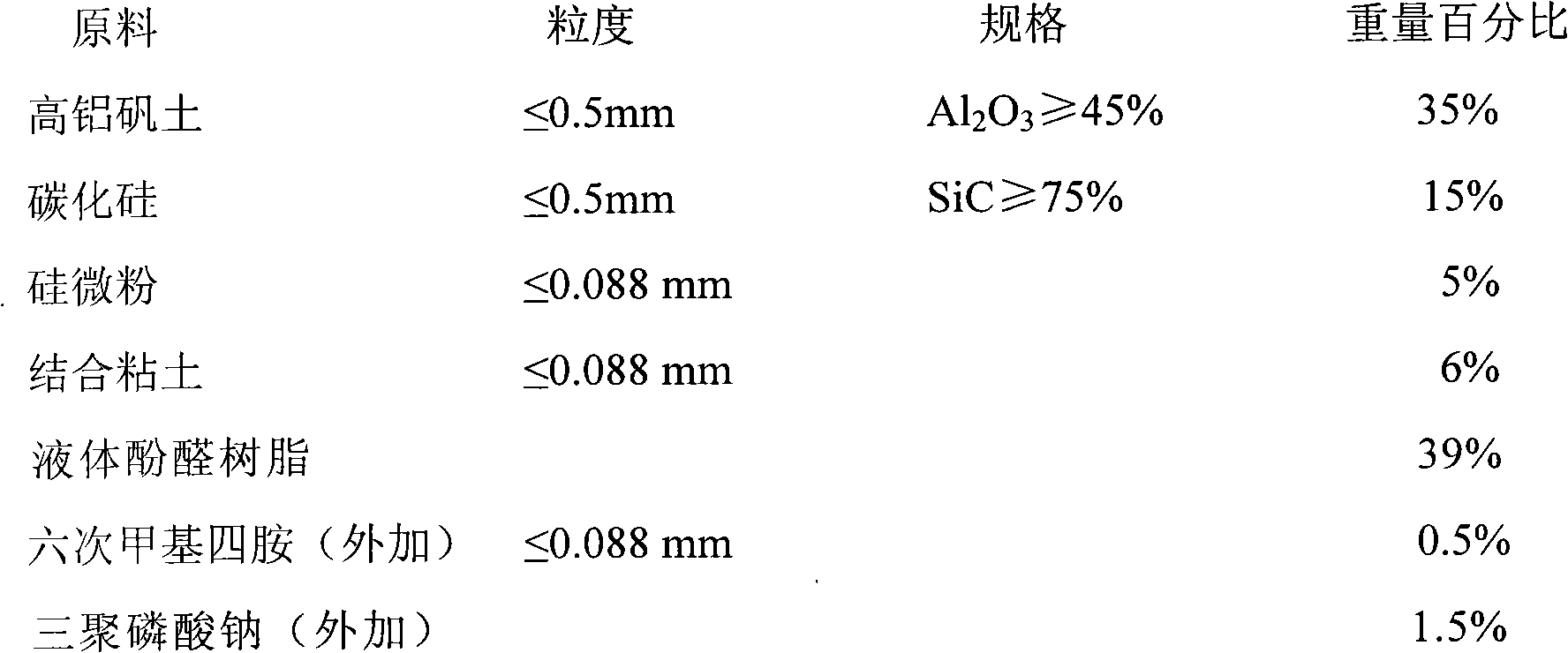

Embodiment 1

[0014] A blast furnace anhydrous pressing mud A, consisting of the following components:

[0015]

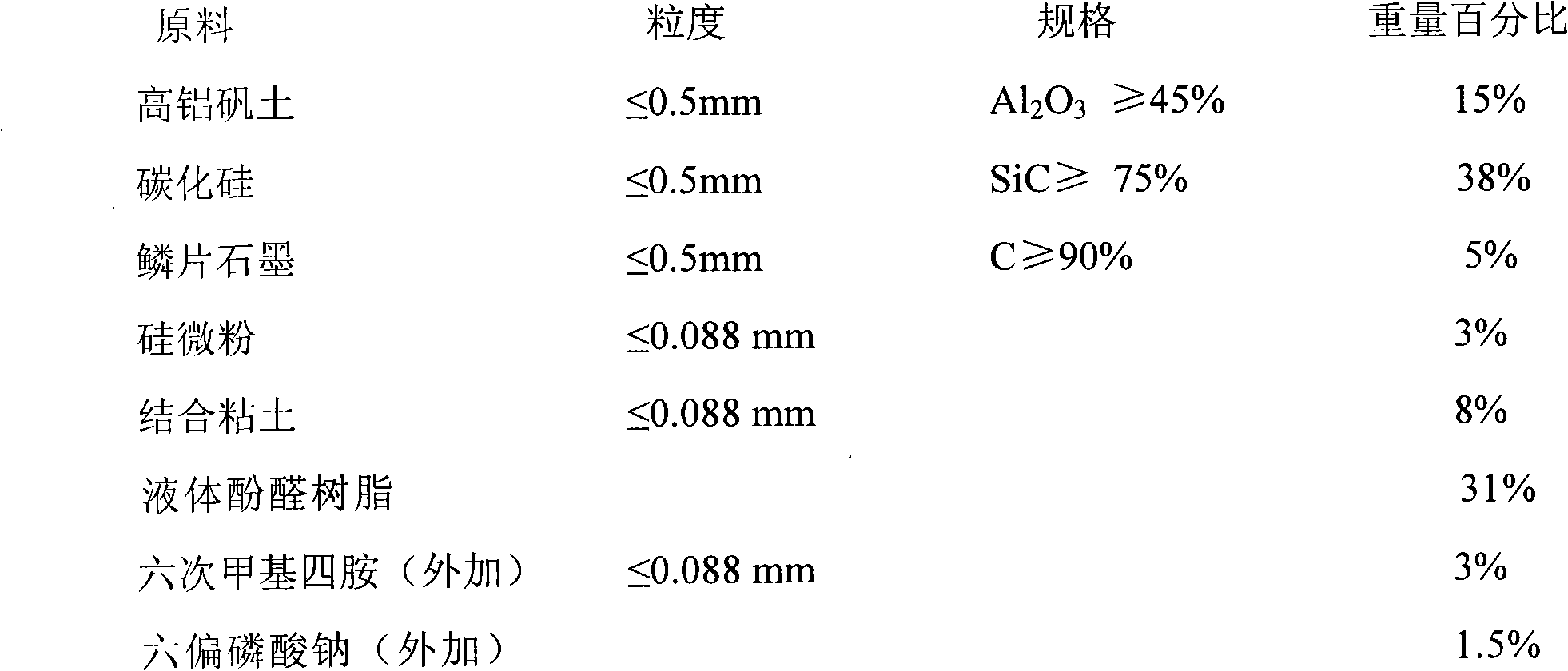

Embodiment 2

[0017] A blast furnace anhydrous press-in mud B, consisting of the following components:

[0018]

Embodiment 3

[0020] A blast furnace anhydrous press mud C, consisting of the following components:

[0021] .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

Anhydrous press-in slurry used for a blast furnace is used for repairing the blast furnace in the damping down process through pumping and belongs to the field of a refractory material in inorganic nonmetallic materials. The anhydrous press-in slurry consists of the following materials by weight: 40-60% of aggregates, 5-15% of matrixes, 25-40% of a binding agent and 1-5% of additives, wherein the aggregates can be one of high bauxite, silicon carbide and a carbon material or a composite of the high bauxite, the silicon carbide and the carbon material, and the aggregate size is less than 0.5mm; the matrixes can be one of silica micropowder and binding clay or a composite of the silica micropowder and the binding clay generally; the binding agent can be a liquid phenolic resin; and the additives can be a curing agent and the like. The mixed powder and the binding agent are pressed in a damaged part of a lining of a furnace shell by a grouting machine and then are cured to form a solid compact whole body, thereby avoiding the damage of a water press-in material used for the blast furnace to the carbon lining after production, so as to shorten the overall time, improve the efficiency and ensure the long-time and stable operation of the blast furnace.

Description

technical field [0001] The invention belongs to the field of inorganic non-metal refractory materials, and in particular relates to a refractory material for blast furnace stave maintenance. Background technique [0002] In the middle and late stages of blast furnace operation, the lining of the furnace body will be damaged to varying degrees, such as the furnace shell is red hot or the cooling wall is burned. In order to improve the service life of the blast furnace, improve the safety factor of the blast furnace, and avoid accidents, it is necessary to maintain the blast furnace regularly, and the excessively long maintenance cycle or too frequent maintenance times will affect the stable operation of the blast furnace, which is not conducive to the smooth production of the blast furnace reached production. The traditional maintenance method needs to stop the furnace. After cooling the furnace, use the water system press-in material to fill the damaged part. Since the wate...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C04B35/66

Inventor 冯运生李平韩忠毅高长贺王治峰马飞马淑龙夏文斌王浩杰刘怀岗吕雪艳孙艳粉

Owner TONGDA REFRACTORY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com