Synthetic method of emulsifier SP-80 for emulsion explosive

A technology of SP-80 and emulsified explosives, which is applied to non-explosive/non-thermal agent components, explosives, offensive equipment, etc., can solve problems such as inaccurate temperature control, insufficient product purity, and slow heating rate, and achieve dispersibility and storage Good stability and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

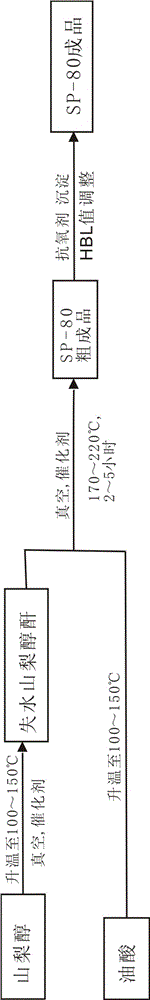

[0026] Such as figure 1 Shown, a kind of synthetic method of emulsion explosive emulsifier SP-80, this synthetic method comprises the following steps:

[0027] 1) Put 13kg of sorbitol with a mass concentration of 70% and catalyst phosphoric acid in a vacuum state (vacuum degree is -0.075 ~ 0.085 MPa), and undergo etherification reaction at 120°C. The reaction time is 70 minutes to generate anhydrous sorbitan ;

[0028] 2) Mix anhydrous sorbitan, oleic acid warmed to 120°C, and a basic catalyst evenly, and perform an esterification reaction at 180°C in a vacuum state (vacuum degree is -0.075 to 0.085 MPa), and the reaction time is 3.5 hours. Produce the primary product of emulsifier SP-80 for emulsion explosives;

[0029] 3) The primary product of emulsifier SP-80 for emulsified explosives is separated by adding antioxidants for precipitation, and after the HLB value adjustment step, the finished product of emulsifier SP-80 for emulsified explosives is produced.

[0030] The...

Embodiment 2

[0034] Such as figure 1 Shown, a kind of synthetic method of emulsion explosive emulsifier SP-80, this synthetic method comprises the following steps:

[0035] 1) Put 13kg of sorbitol with a mass concentration of 70% and catalyst phosphorous acid in a vacuum state (vacuum degree is -0.075 ~ 0.085 MPa), and an etherification reaction occurs at 125°C. The reaction time is 50 minutes, and anhydrous sorbitol is produced. anhydride;

[0036] 2) Mix anhydrous sorbitan, oleic acid warmed to 125°C, and a basic catalyst evenly, and perform esterification reaction at 200°C in a vacuum state (vacuum degree is -0.075 to 0.085 MPa), and the reaction time is 5 hours. Produce the primary product of emulsifier SP-80 for emulsion explosives;

[0037] 3) The primary product of emulsifier SP-80 for emulsified explosives is separated by adding antioxidants for precipitation, and after the HLB value adjustment step, the finished product of emulsifier SP-80 for emulsified explosives is produced. ...

Embodiment 3

[0042] Such as figure 1 Shown, a kind of synthetic method of emulsion explosive emulsifier SP-80, this synthetic method comprises the following steps:

[0043]1) Put 13 kg of sorbitol with a mass concentration of 70% and the catalyst p-toluenesulfonic acid in a vacuum state (vacuum degree is -0.075 ~ 0.085 MPa), and an etherification reaction occurs at 100 ° C. The reaction time is 80 minutes, resulting in dehydration Sorbitan;

[0044] 2) Mix anhydrous sorbitan, oleic acid warmed to 100°C, and a basic catalyst evenly, and perform an esterification reaction at 220°C in a vacuum state (vacuum degree is -0.075 to 0.085 MPa), and the reaction time is 4.5 hours. Produce the primary product of emulsifier SP-80 for emulsion explosives;

[0045] 3) The primary product of emulsifier SP-80 for emulsified explosives is separated by adding antioxidants for precipitation, and after the HLB value adjustment step, the finished product of emulsifier SP-80 for emulsified explosives is produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com