Phosphate group based small-molecule water/alcohol soluble material and preparation method and application thereof

A phosphonate group, alcohol-soluble material technology, used in semiconductor/solid-state device manufacturing, chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, etc. Problems such as polymer molecular weight and structural uncertainty, to achieve the effect of easy purification, avoid batch instability, and strong electrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

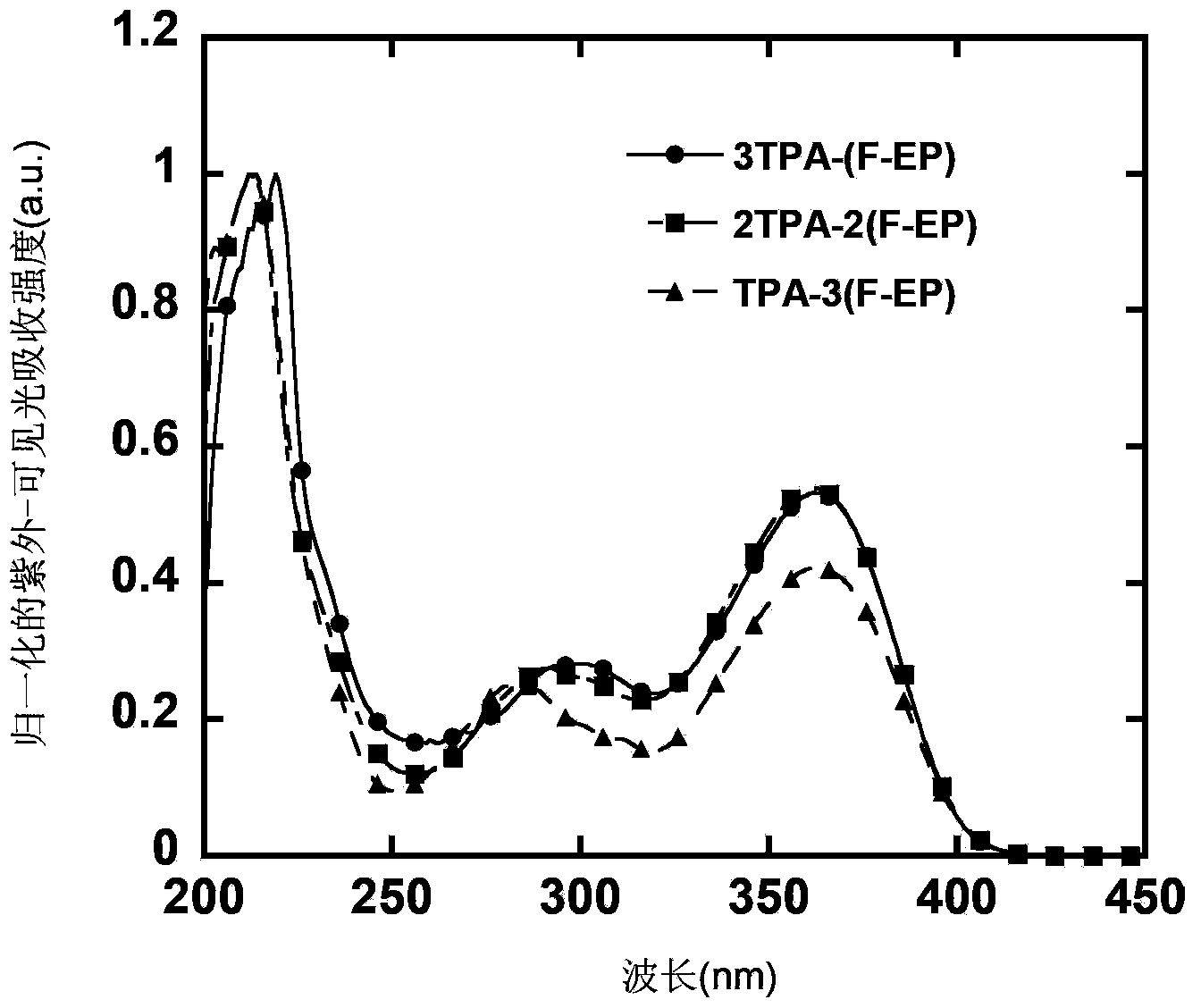

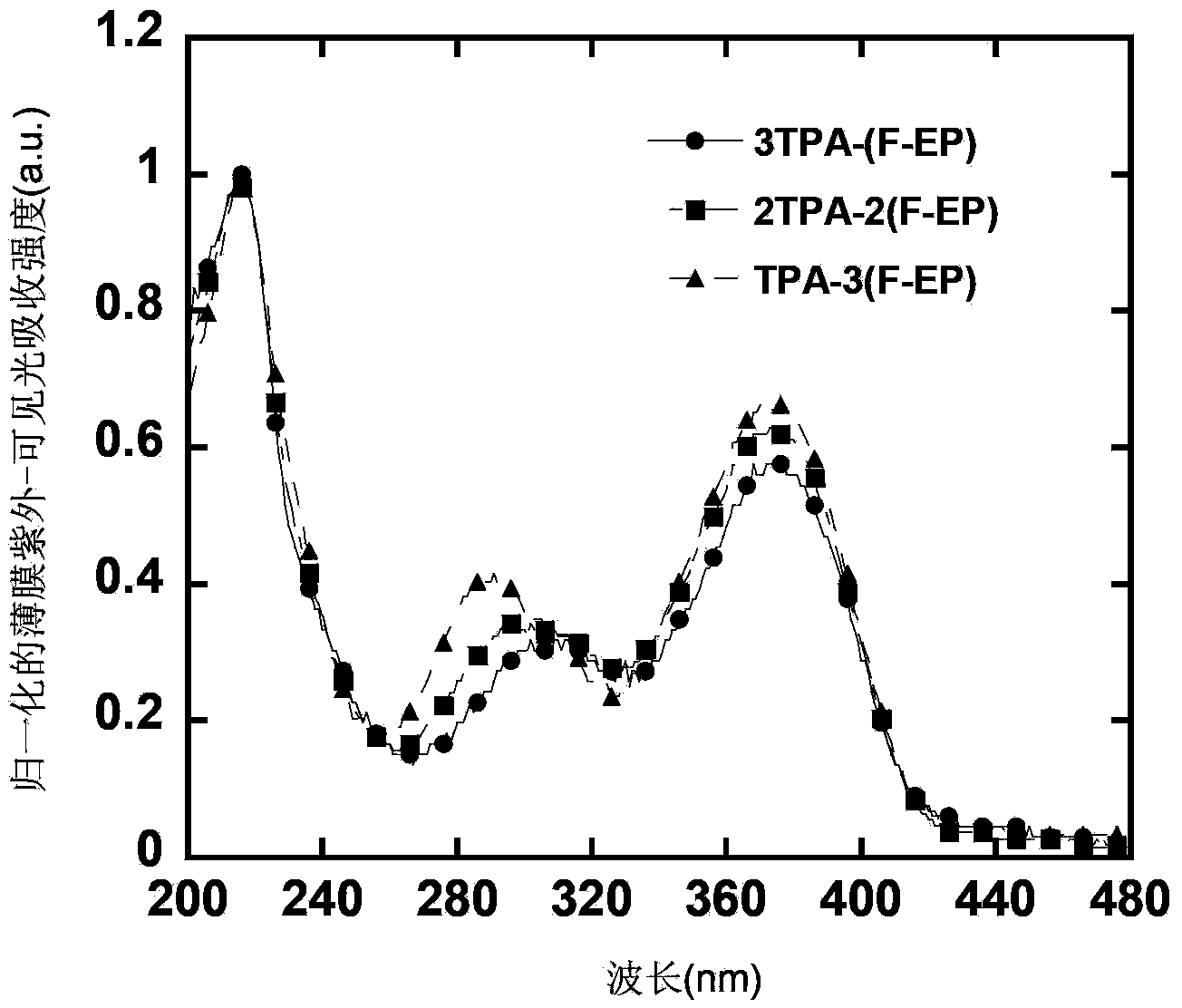

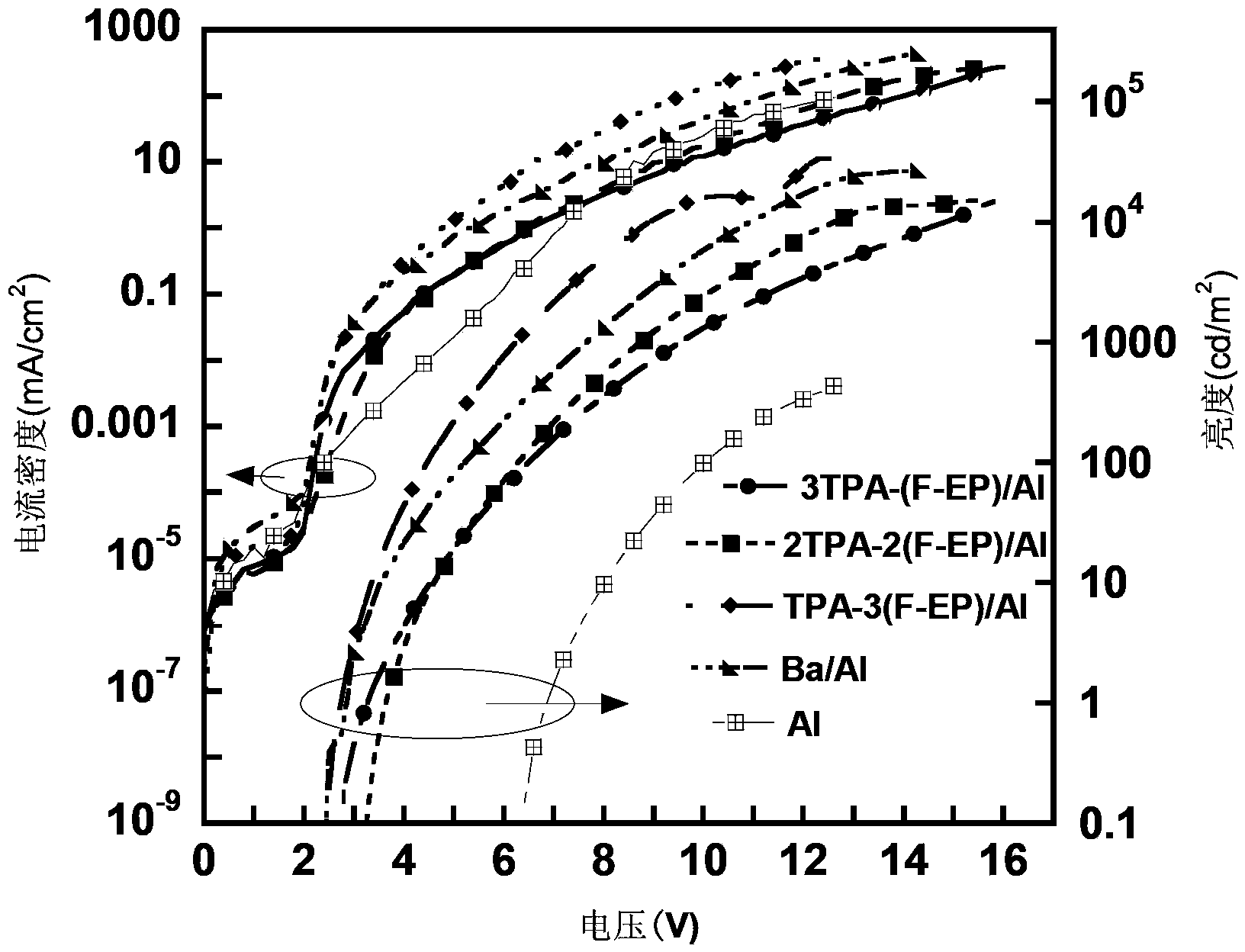

Examples

Embodiment 1

[0041] A kind of small molecule water / alcohol soluble material based on phosphonate group, its synthetic method comprises the following steps:

[0042] Step 1: Synthesis of 2-bromo-9,9-di(6'-bromohexyl)fluorene

[0043]

[0044]Under nitrogen protection, 200ml of 50% aqueous potassium hydroxide solution, phase transfer catalyst tetrabutylammonium bromide (3.87g, 0.012mol) and 1,6-dibromohexane (109.79g, 0.45 mol), heated to 70°C and stirred for 0.5 hours. After that, 2-bromofluorene (22.05 g, 0.09 mol) was added slowly, and reacted at 75° C. for 2 hours. Add appropriate amount of concentrated hydrochloric acid to neutralize and cool with ice water. Extract with dichloromethane, wash the organic layer 3 times with concentrated brine, dry over anhydrous magnesium sulfate, filter with suction, and remove the solvent and excess 1,6-dibromohexane from the filtrate under reduced pressure to obtain a yellow liquid. Using petroleum ether as the mobile phase to pass through the c...

Embodiment 2

[0077] A kind of small molecule water / alcohol soluble material based on phosphonate group, its synthetic method comprises the following steps:

[0078] Steps one to seven are the same as steps one to seven of embodiment 1;

[0079] Step 8: Synthesis of Compound 2TPA-2(F-EP)

[0080]

[0081] Under nitrogen protection, 2-boronic acid pinacol ester-9,9-bis(6'-phosphoethylhexyl)fluorene (2.20 g, 3.0 mmol) was dissolved in 12 ml of toluene and added to a 100 ml reactor, followed by Join N 4 ,N 4 -Bis(4-iodophenyl)-N 4 ,N 4’ -Diphenylbiphenyl-4,4'-diamine (0.89g, 1.2mmol), 18ml of toluene, after stirring for half an hour, add 15ml of 2 mol / liter potassium carbonate solution, 10ml of absolute ethanol, and the reaction system is The catalyst Pd(PPh 3 ) 4 (0.084g, 0.072mmol), stirred for half an hour and then heated to 80°C for 24 hours. After cooling to room temperature, it was extracted with ethyl acetate, washed three times with saturated brine, and the obtained organic ...

Embodiment 3

[0084] A kind of small molecule water / alcohol soluble material based on phosphonate group, its synthetic method comprises the following steps:

[0085] Steps one to four are the same as steps one to four of embodiment 1;

[0086] Step five: the synthesis of compound TPA-3 (F-EP)

[0087]

[0088] Under nitrogen protection, 2-boronic acid pinacol ester-9,9-bis(6'-phosphoethylhexyl)fluorene (3.51g, 4.8mmol) was dissolved in 15ml of toluene and added to a 250ml reactor, followed by Add 4,4',4"-triiodotriphenylamine (0.75g, 1.2mmol), 20ml of toluene, stir for half an hour, add 15ml of 2 mol / L potassium carbonate solution, 10ml of absolute ethanol, and the reaction system is in a nitrogen atmosphere Add catalyst Pd(PPh 3 ) 4 (0.208g, 0.18mmol), stirred for half an hour and then heated to 80°C for 24 hours. After cooling to room temperature, it was extracted with ethyl acetate, washed three times with saturated brine, and the obtained organic layer was dried over anhydrous ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com