Method for preparing BOPP (Biaxially-oriented Polypropylene)

A polypropylene and ethylene technology, applied in the field of BOPP special polypropylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Heat the 5L high-pressure reactor to vacuumize, remove air and water, replace with nitrogen, repeat three times, and then add MgCl 2 Loaded TiCl 4 Catalyst solid component 20mg, the content of Ti in the solid component is 2.36wt%, the addition of triethyl aluminum is Al / Ti (mol)=600, cyclohexylmethyl dimethoxy silicon, n-propylene triethoxy Silane, the molar ratio of the two is 70:30, the molar ratio of the two external electron donors to Ti is 20, and then 16 mmol hydrogen and 1.2 kg propylene are added. Close the reaction kettle, raise the temperature of the kettle to 70°C, and start polymerization. After 2 hours of reaction, discharge unreacted propylene to obtain polypropylene particles. The melt index of polypropylene is 2.8gPP / 10min, and the isotacticity is 97.2%. After the polypropylene sample is analyzed by SSA, the thickness of the largest lamella in polypropylene is 25.44nm, and the area ratio of the largest peak is 12%.

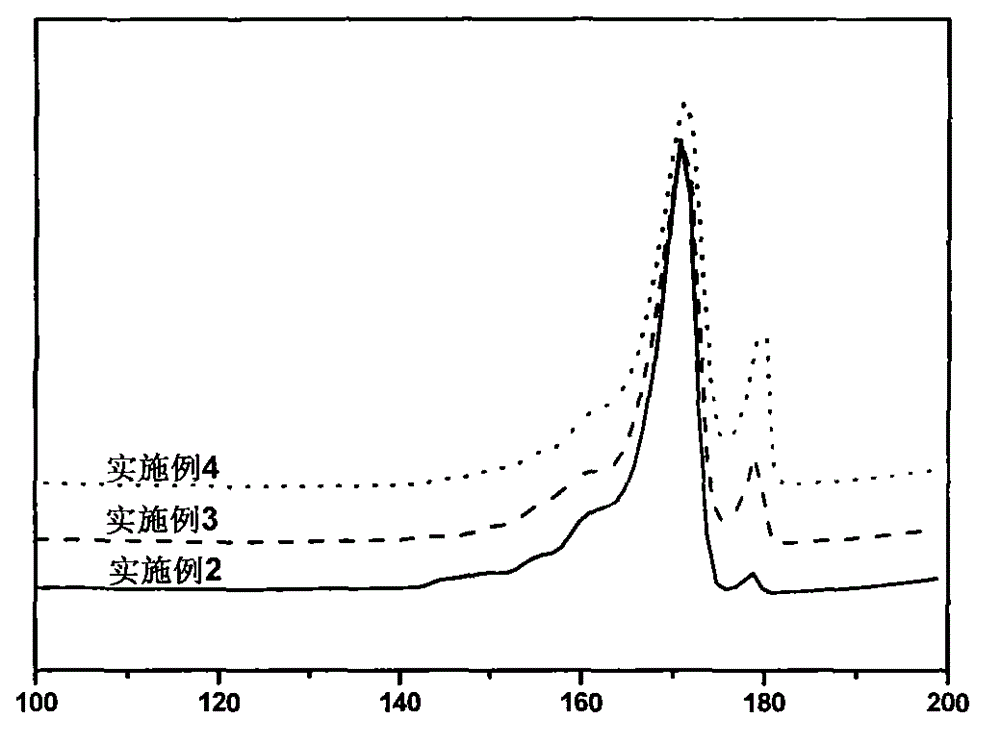

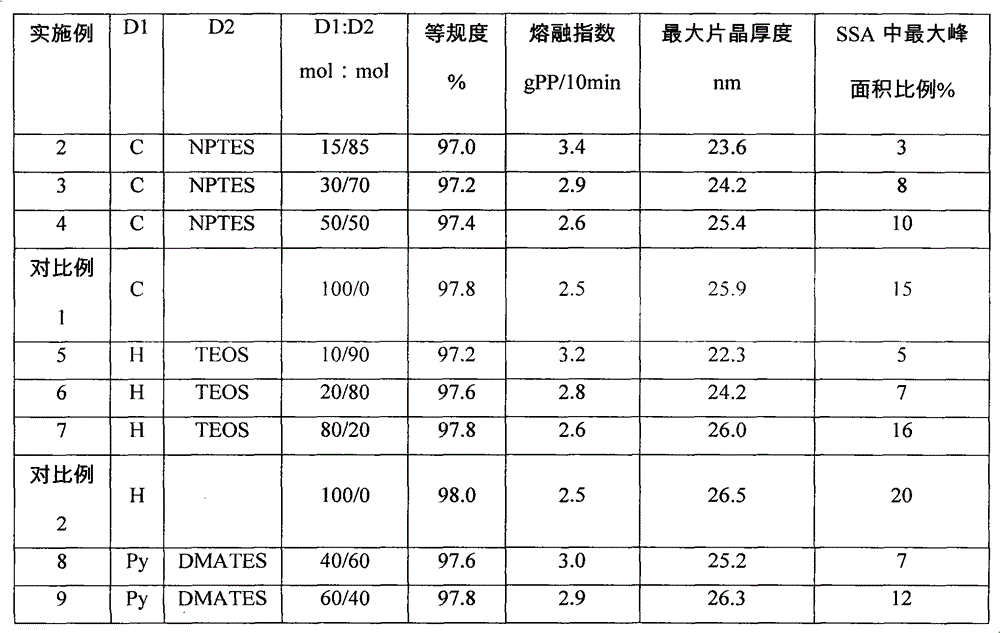

Embodiment 2-9

[0048] The polymerization process was the same as in Example 1, only the type and ratio of the external electron donor were changed. The results are shown in Table 1.

Embodiment 10-11

[0052] The polymerization process is the same as in Example 1, except that 0.6% butene-1 by mass of propylene is added, and the type and ratio of external electron donors are changed. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com