Cerium-terbium co-doped borophosphate light-emitting film and preparation method thereof as well as organic electroluminescence device

A technology of luminescent film and borophosphate, which is applied in the field of cerium-terbium co-doped borophosphate luminescent film and its preparation, and organic electroluminescent devices, which can solve the problems of limited application and uncontrollable ratio of phosphate and rare earth elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

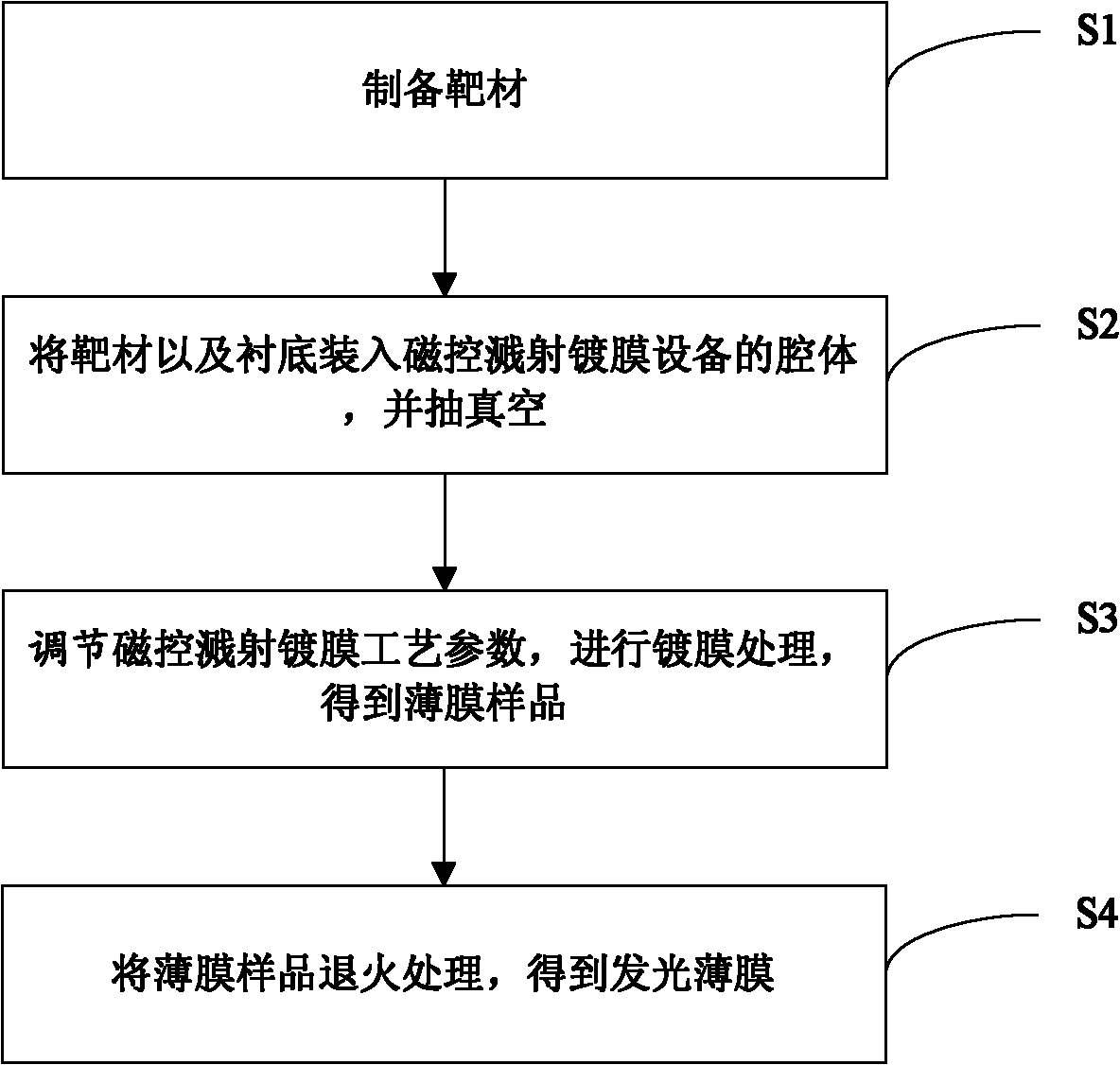

[0018] Step S1, preparation of ceramic targets: according to the general chemical formula Sr(PO 4 ) x (BO 3 ) 1-x :mCe 3+ , nTb 3+ The stoichiometric ratio of each element in SrO, H 3 PO 4 、H 3 BO 3 、Ce 2 o 3 and Tb 4 o 7 , after uniform mixing, sintering at 900-1300°C (preferably 1250°C), and cooling naturally to obtain a target sample, which is cut into a target with a diameter of 50mm and a thickness of 2mm; where, the value of x The range is 0.4-0.8, the range of m is 0.012-0.036, and the range of n is 0.011-0.054; preferably, the value of x is 0.6, the value of m is 0.024, and the value of n is 0.032.

[0019] Step S2, put the target and substrate in step S1 into the vacuum chamber of the magnetron sputtering coating equipment, and use a mechanical pump and a molecular pump to pump the vacuum of the chamber to 1.0×10 -3 Pa~1.0×10 -5 Pa, preferably 5.0×10 -4 Pa;

[0020] Step S3, adjusting the magnetron sputtering coating process parameters as follows: the ...

Embodiment 1

[0027] 1. Select SrO, H 3 PO 4 、H 3 BO 3 、Ce 2 o 3 and Tb 4 o 7 , and their mass numbers are: SrO is 9.88g, H 3 PO 4 5.88g, H 3 BO 3 2.48g, Ce 2 o 3 0.364g, Tb 4 o 7 0.547g; these powders were uniformly mixed, sintered at 1250°C, and cooled naturally to obtain target samples, which were cut into targets with a diameter of 50 mm and a thickness of 2 mm;

[0028] 2. Put the target into the vacuum chamber of the magnetron sputtering coating equipment;

[0029] 3. Clean the glass ultrasonically with acetone, absolute ethanol and deionized water successively, and perform oxygen plasma treatment on it, and then put it into the vacuum chamber of the magnetron sputtering coating equipment; among them, the distance between the target and the glass Set to 60mm;

[0030] 4. Use a mechanical pump and a molecular pump to pump the vacuum of the vacuum chamber of the magnetron sputtering coating equipment to 5.0×10 -4 Pa;

[0031] 5. Adjust the process parameters of magnetr...

Embodiment 2

[0034] 1. Select SrO, H 3 PO 4 、H 3 BO 3 、Ce 2 o 3 and Tb 4 o 7 , the mass numbers are: SrO is 10.19g, H 3 PO 4 4.9g, H 3 BO 3 3.1g, Ce 2 o 3 0.182g, Tb 4 o 7 0.182g; these powders are uniformly mixed, sintered at 900°C, and cooled naturally to obtain target samples, which are cut into targets with a diameter of 50 mm and a thickness of 2 mm;

[0035] 2. Put the target into the vacuum chamber of the magnetron sputtering coating equipment;

[0036] 3. Clean the glass ultrasonically with acetone, absolute ethanol and deionized water successively, and perform oxygen plasma treatment on it, and then put it into the vacuum chamber of the magnetron sputtering coating equipment; among them, the distance between the target and the glass Set to 45mm;

[0037] 4. Use a mechanical pump and a molecular pump to pump the vacuum of the vacuum chamber of the magnetron sputtering coating equipment to 1.0×10 -3 Pa;

[0038] 5. Adjust the process parameters of magnetron sputter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com