Preparation method of carbon fiber surface nano CoFeB microwave-absorbing coating

A wave-absorbing coating and carbon fiber technology, which is applied in the field of carbon fiber surface coating preparation, can solve the problems of poor impedance matching characteristics and excessively high carbon fiber dielectric constant, and achieve good wave-absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

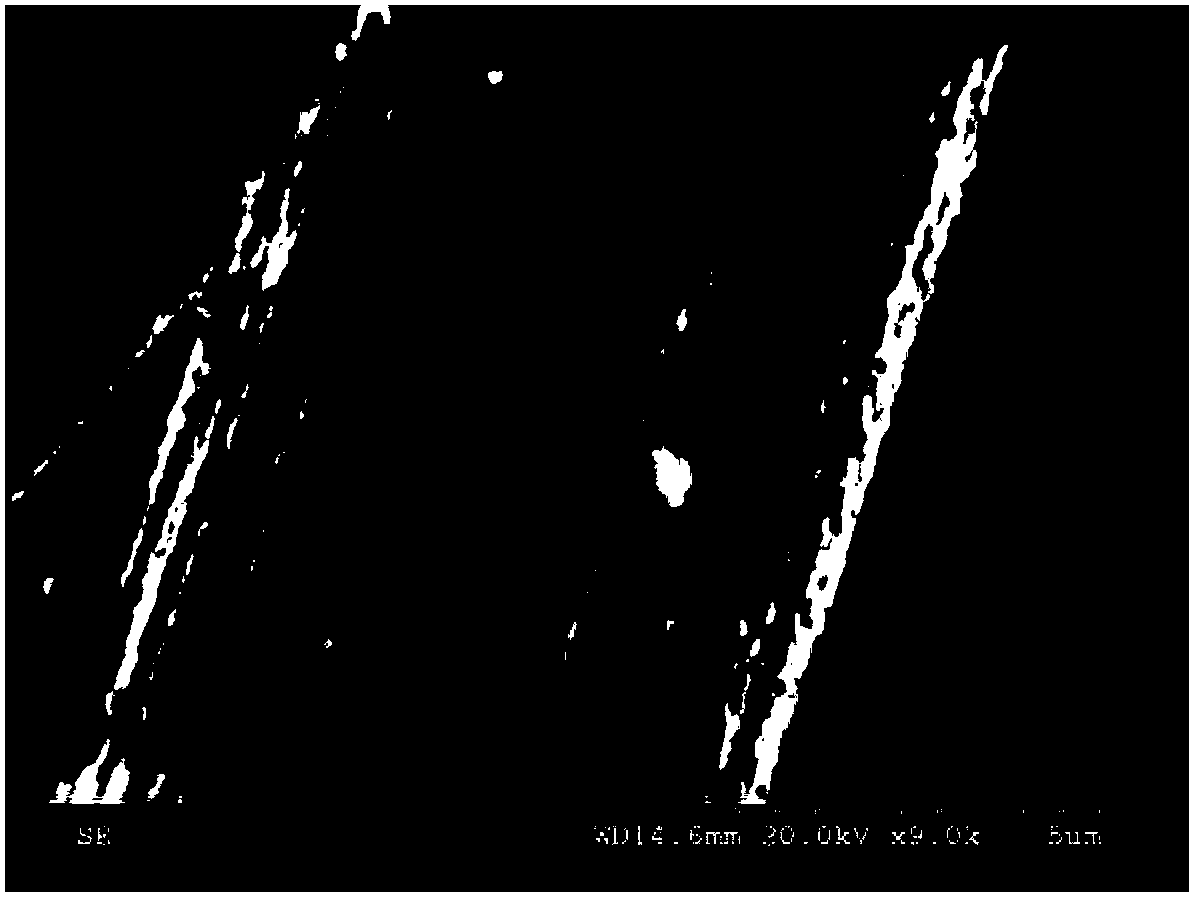

Image

Examples

specific Embodiment approach 1

[0007] Specific Embodiment 1: The preparation method of a nano-CoFeB wave-absorbing coating on the surface of carbon fiber in this embodiment is realized according to the following steps: 1. Keep the carbon fiber at 400°C for 10-30 minutes; 2. Treat the carbon fiber after step 1 Ultrasonic cleaning in acetone for 10 to 30 minutes; 3. Soak the carbon fibers treated in step 2 in nitric acid with a mass percentage of 65% for 0.5 to 4 hours, and then wash them with deionized water for 5 to 6 times; 4. Put the carbon fiber processed in step 3 into SnCl 2 Sensitize in a mixed solution with HCl, the sensitization time is 10-30min, and obtain the sensitized carbon fiber; 5. Put the sensitized carbon fiber into PdCl 2 Activate in a mixed solution with HCl for 10-30 minutes to obtain activated carbon fibers; 6. Put the activated carbon fibers into the plating solution at 20-85°C for 0.1-20 minutes to complete the carbon fiber surface The preparation of nano-CoFeB wave-absorbing coating...

specific Embodiment approach 2

[0009] Embodiment 2: This embodiment is different from Embodiment 1 in that in Step 1, the carbon fiber is kept at 400° C. for 15 minutes. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0010] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 2, the carbon fiber is put into acetone and ultrasonically cleaned for 20 minutes. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com