Method for adjusting control parameters of follow-up device of mechanical device

A technology of follow-up device and adjustment method, which is applied in general control system, control/adjustment system, adaptive control, etc., can solve the problem of blind adjustment of the control parameters of the follow-up controller, time-consuming and laborious debugging of the follow-up device, and poor control performance. Difficult to meet and other problems, to achieve the effect of improving static and dynamic performance, reducing blindness, reducing volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

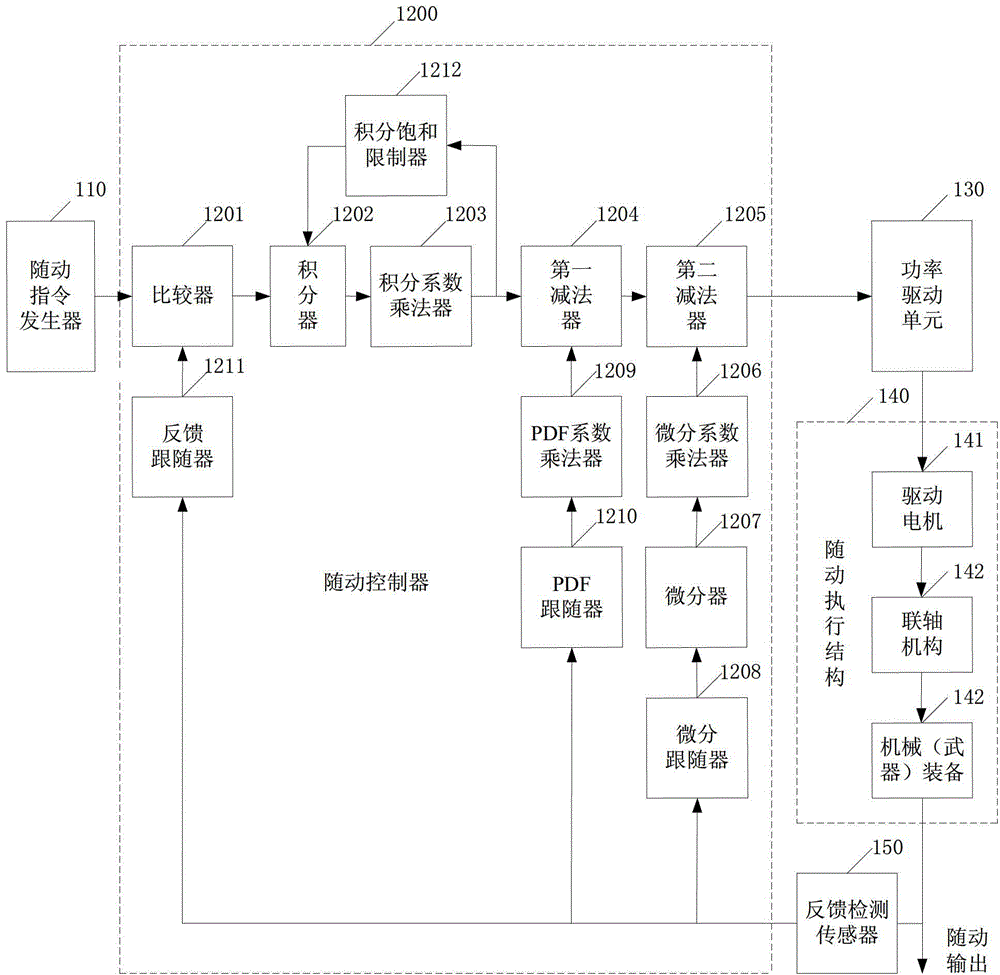

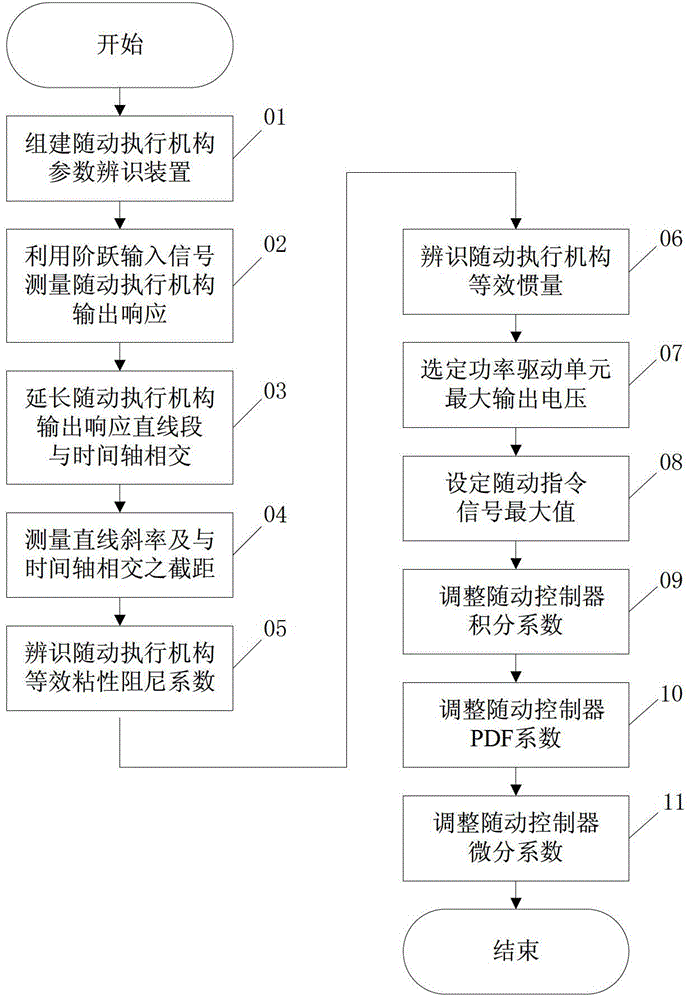

[0030] In order to deepen the understanding of the present invention, below in conjunction with appendix figure 1 And attached figure 2 Specific embodiments of the present invention are further described in detail.

[0031] as attached figure 1 Shown is a block diagram of the follow-up device for mechanical equipment according to the embodiment of the present invention. Described follow-up device is made up of follow-up command generator 110, follow-up controller 120, power drive unit 130, follow-up actuator 140 and feedback detection sensor 150, follow-up command generator 110, follow-up controller 120, power Drive unit 130, follow-up actuator 140 and feedback detection sensor 150 are circularly connected clockwise in order to form a closed-loop device; said follow-up controller 120 is composed of comparator 1201, integrator 1202, integral coefficient multiplier 1203, first subtraction 1204, second subtractor 1205, differential coefficient multiplier 1206, differentiator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com