Printed circuit board surface processing method and printed circuit board

A printed circuit board and surface treatment technology, which is applied to the surface treatment method of printed circuit boards and the field of printed circuit boards, can solve problems such as easy oxidation pollution, influence on PCB reliability, complicated process, etc., and achieve short surface treatment process and no hair loss. The problem of black heterochromaticity and the effect of relatively poor market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

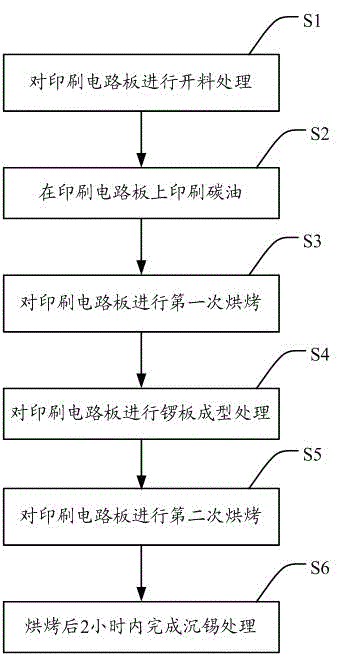

[0030] see figure 1 , which is a flow chart of the method for surface treatment of a printed circuit board of the present invention. As shown in the figure, the printed circuit board surface treatment method includes the following steps in sequence:

[0031] S1. Cutting the printed circuit board;

[0032] S2, printing carbon oil on the printed circuit board;

[0033] S3. Baking the printed circuit board for the first time;

[0034] S4, carry out gong board forming process to printed circuit board;

[0035] S5, the printed circuit board is baked for the second time;

[0036] S6. Com...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap