Pipe type circulation-based reaction apparatus

A technology of reaction device and tube type, applied in feeding device, chemical/physical/physical-chemical fixed reactor, chemical/physical/physical-chemical reactor, etc. The effect of suppressing the reduction of the generation rate, suppressing the concentration variation, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

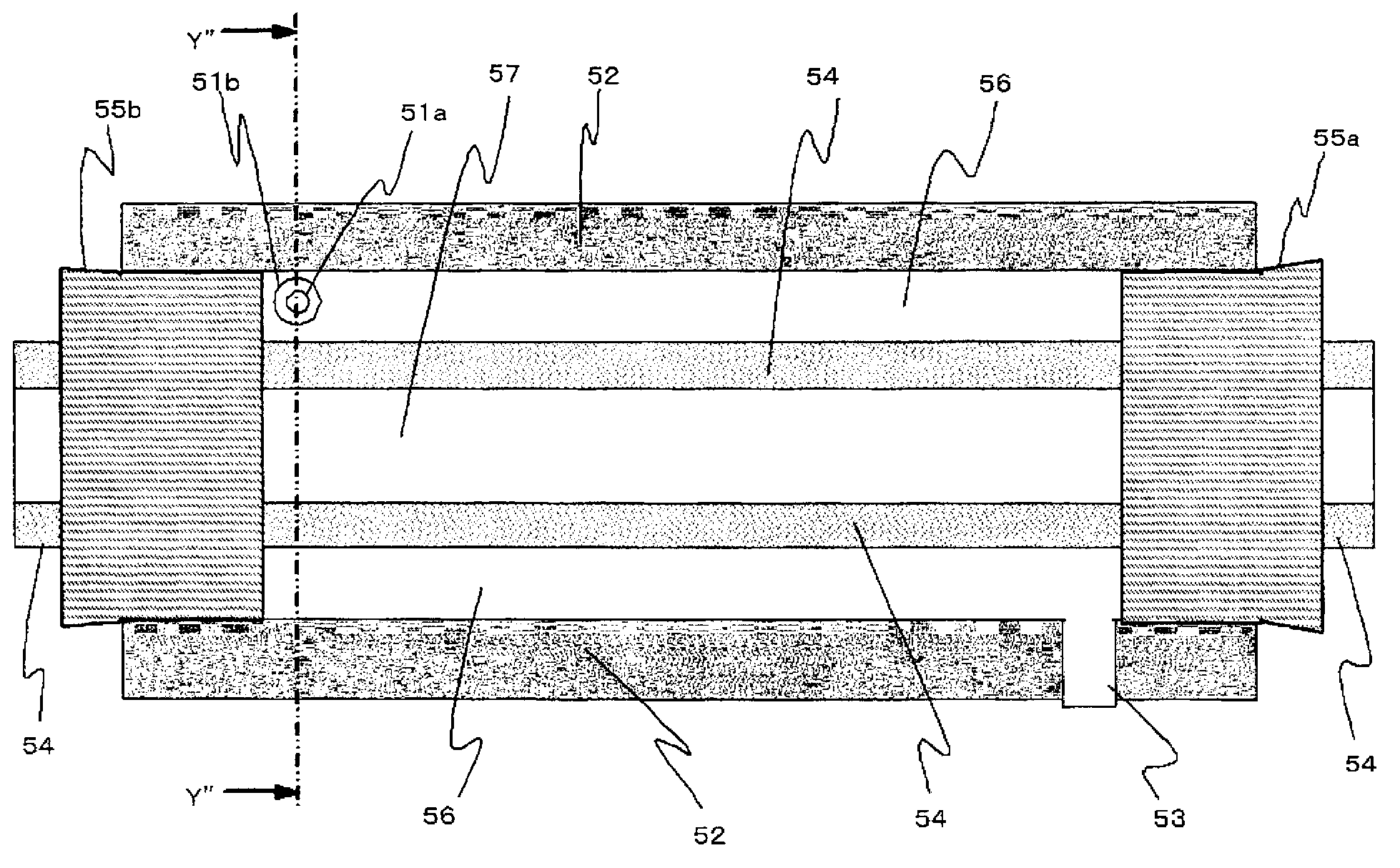

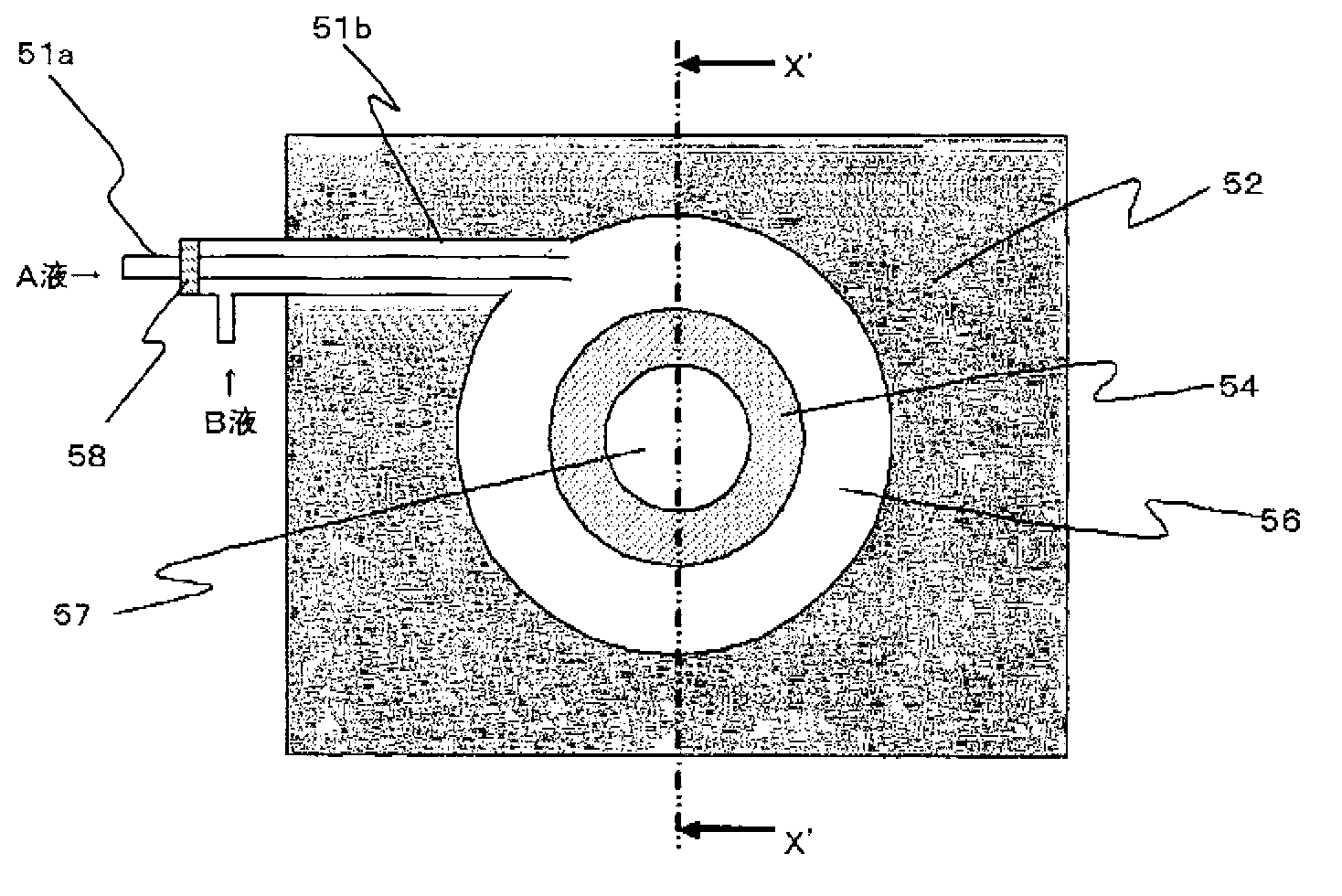

[0049] figure 1 It is an X' arrow view of one embodiment of the tubular flow-through reactor of the present invention. figure 2 yes figure 1 The Y" view of the tubular flow-through reaction device shown.

[0050] figure 1 The shown reaction device of the present invention has a double tube structure composed of an outer cylinder member 52 and a core member 54 . in addition, figure 1 The shown device has a double tube structure, however, if necessary, further tubes may be provided on the outside of the outer cylinder member 52 to have a triple tube structure. exist figure 1 In the illustrated embodiment, the outer cylinder member 52 is formed by perforating polygonal columns to form an inner cavity through which fluid can flow, but the present invention is not limited thereto. For example, a straight pipe may be used, or a flat plate may be excavated to form a groove, and a cover may be placed there to form a cavity through which a fluid can flow. In addition, in figur...

no. 2 approach )

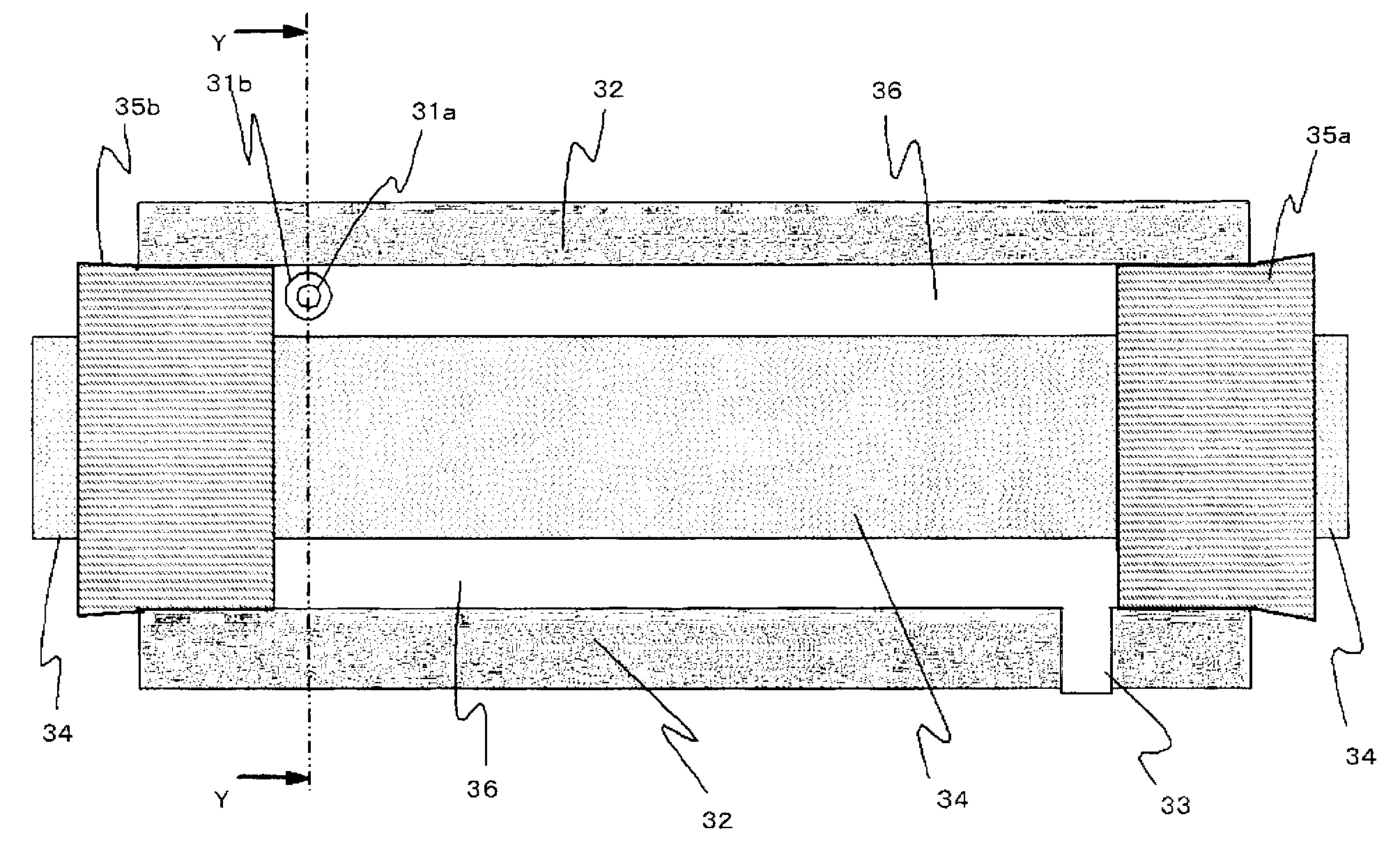

[0071] image 3It is an X-direction view of the second embodiment of the tubular flow reaction device of the present invention. Figure 4 yes image 3 Y-direction view of the tubular flow-through reactor shown. Such as image 3 and Figure 4 The illustrated tubular flow-through reactor has the same structure as that of the first embodiment except that the core member and the circular tube 54 are replaced with the column 34 .

no. 3 approach )

[0073] Figure 5 It is a Z' view of the third embodiment of the tubular flow-through reactor of the present invention. Figure 6 yes Figure 5 The y' view of the tubular flow-through reactor shown. Such as Figure 5 and Figure 6 In the illustrated tubular flow-through reactor, the fluid supply channels are connected in a direction substantially perpendicular to the peripheral surface. In addition, in the present invention, the so-called substantially orthogonal or substantially right angle is 90°±45°. When the connection is made in a direction substantially perpendicular to the peripheral surface, the supplied fluid collides with the core member and spreads to the left and right of the annular reaction channel, resulting in complicated convection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com