Preparation method of NaY(98-X)% F4:X%Yb, 2%Er@NaDyF4 in core-shell structure

A core-shell structure, 98-X technology, applied in the field of preparation of up-conversion reflective materials, can solve the problems of reducing up-conversion luminous efficiency and luminous intensity, and the influence of luminous centers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

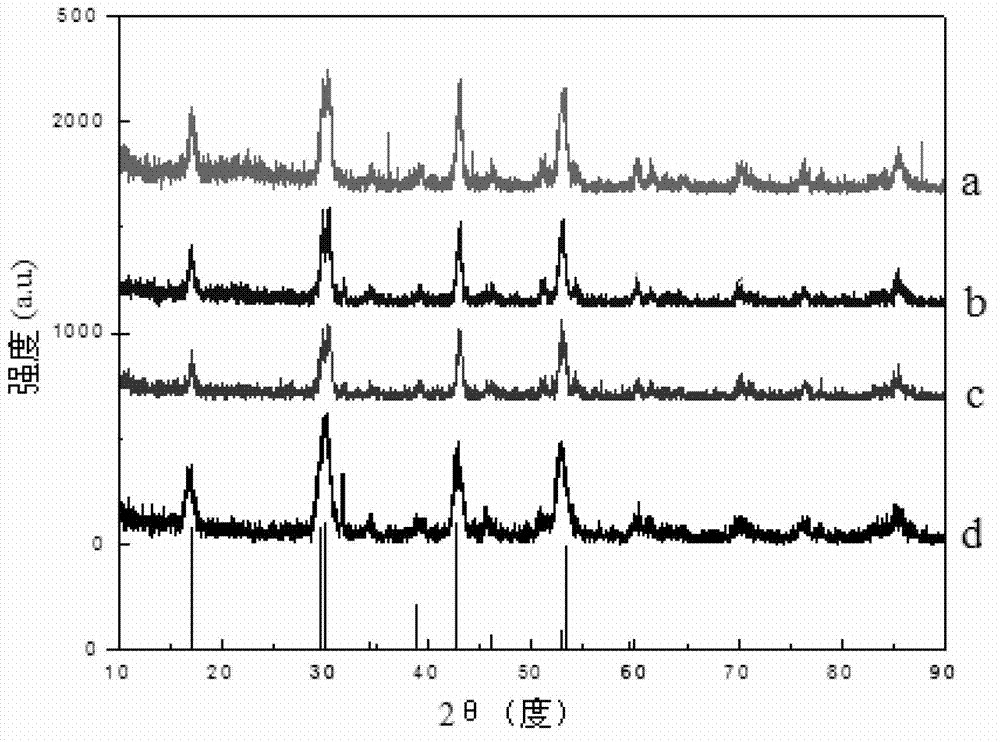

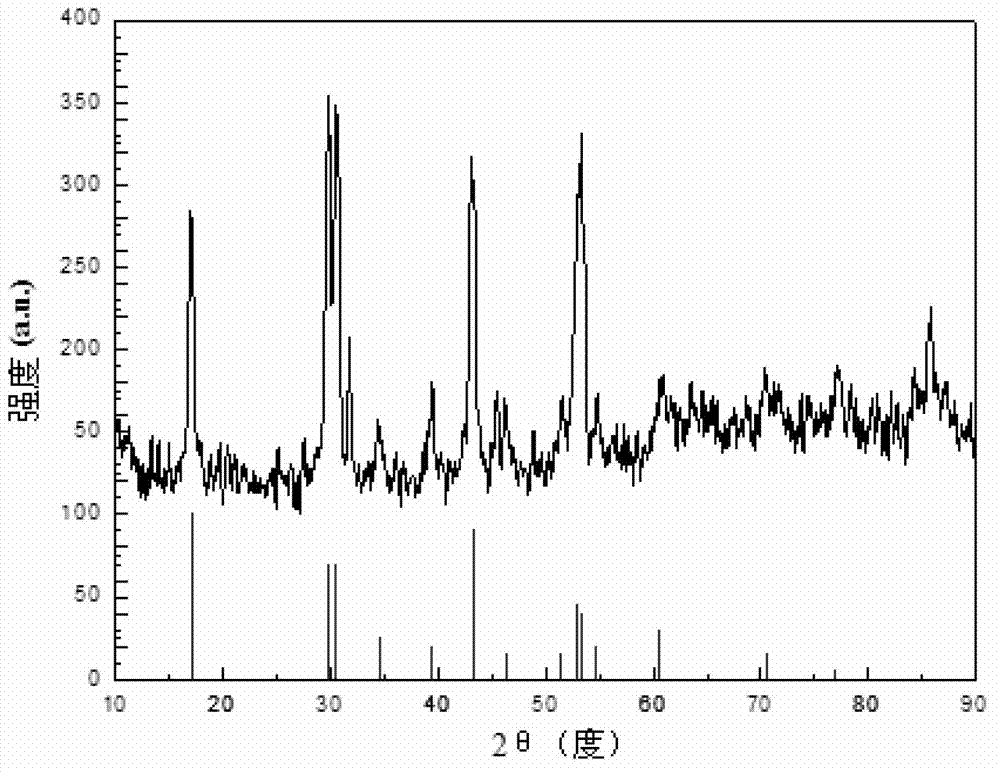

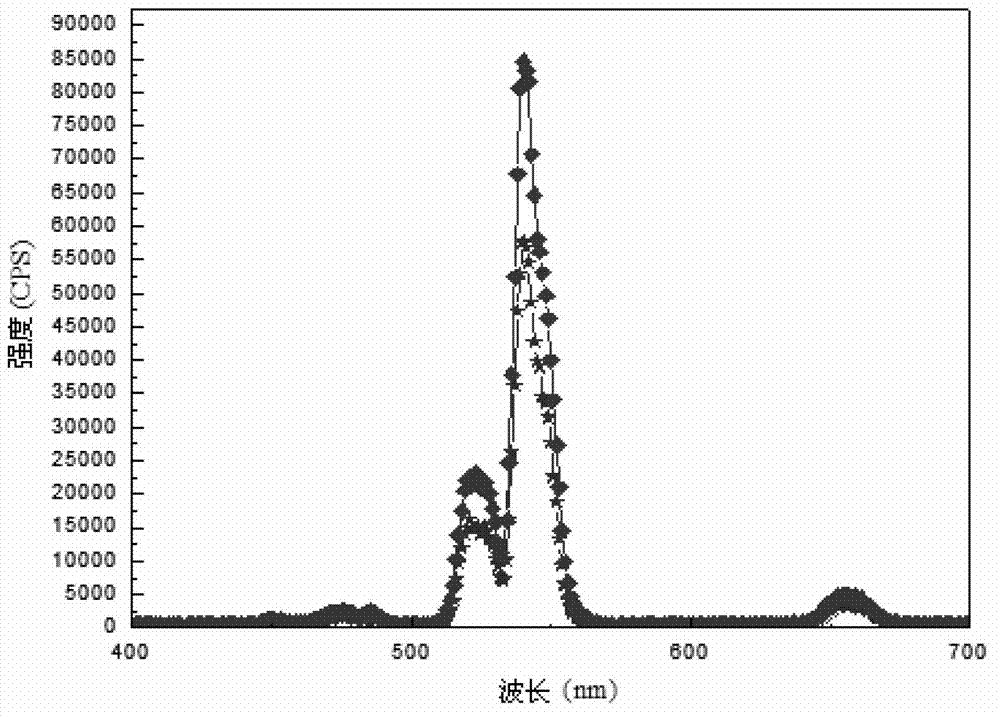

[0024] Specific embodiment one: In this embodiment, the core-shell structure NaY(0.98-X)%F 4 :X%Yb, 2%Er@NaDyF 4 The preparation method is carried out according to the following steps:

[0025] 1. Weigh YCl according to the ratio of Y element, Yb element and Er element molar ratio (98-X): X: 2 3 ·6H 2 O, ErCl3 ·6H 2 O and YbCl 3 ·6H 2 O, then YCl 3 ·6H 2 O, ErCl 3 ·6H 2 O and YbCl 3 ·6H 2 O was dissolved in a mixture of oleic acid and octadecene and mixed, then stirred at 160°C until a light yellow solution was obtained, and cooled to room temperature to obtain a mixed solution;

[0026] The volume ratio of oleic acid and octadecene in the mixture of oleic acid and octadecene described in step 1 is 1: 4~1;

[0027] 2. Add NH to the mixed solution 4 Anhydrous methanol solution of F and NaOH, let stand for 30min, then heat to 110°C at a rate of 2K / min in an argon atmosphere, then keep at 110°C for 30min, and then heat to 300°C at a rate of 20K / min , and kept for 60...

specific Embodiment approach 2

[0035] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the volume ratio of oleic acid and octadecene in the mixture of oleic acid and octadecene described in step 1 is 3:7. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0036] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the volume ratio of oleic acid to octadecene in the mixture of oleic acid and octadecene described in step 1 is 2:3. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com