Manganese recovery method based on capacitance absorption concentration

一种电容吸附、回收方法的技术,应用在循环经济领域,达到生产工艺简单、减少污染、克服成本较高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

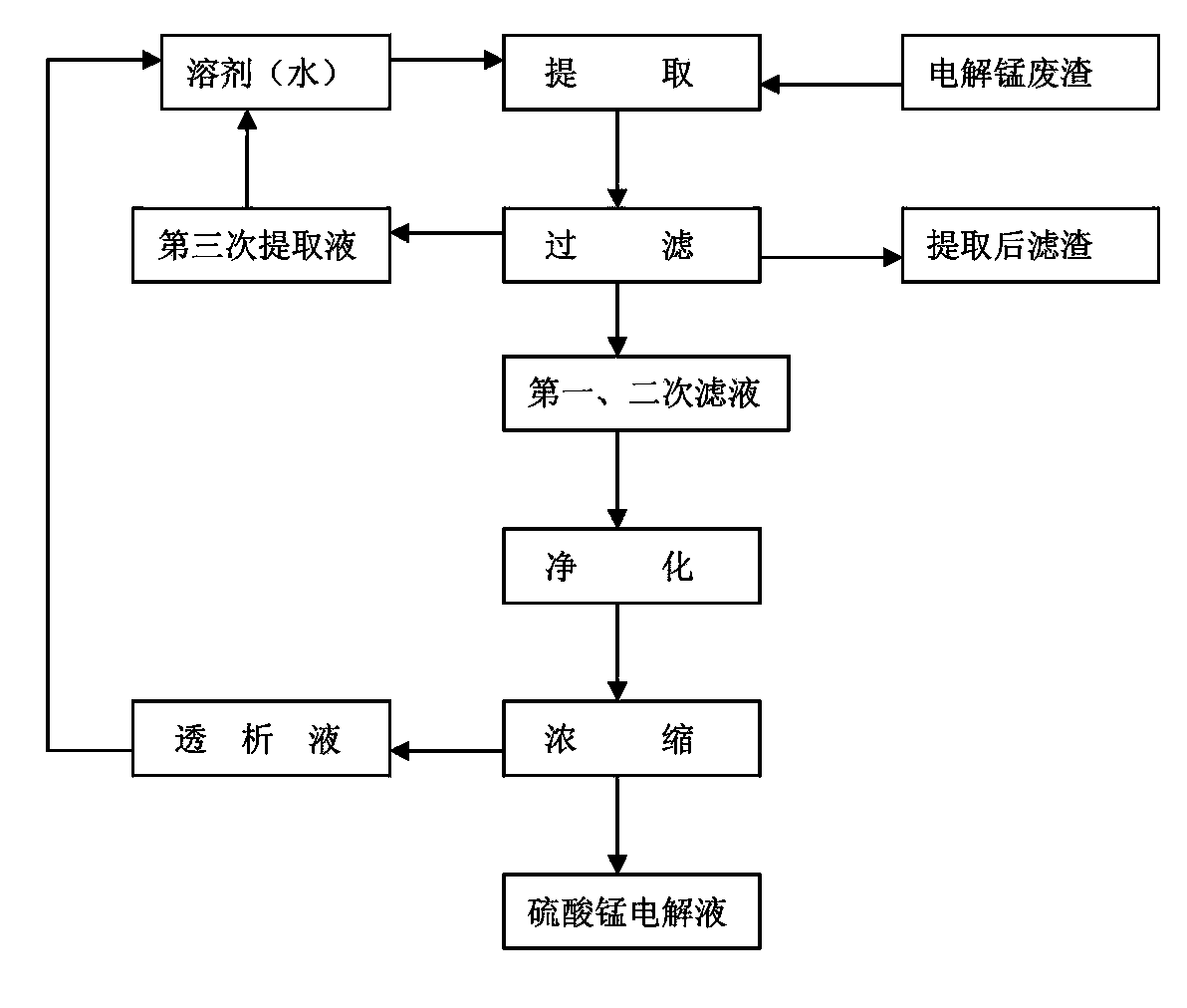

[0029] Reclaim manganese from a certain electrolytic manganese waste residue, and the recovery steps of its manganese sulfate are as follows:

[0030] Step (1) Extraction: ①, the first extraction: transport the electrolytic manganese waste residue to the extraction tank through the conveyor belt, add water at 20°C, the mass ratio of residue to water is 1:1, and start the mixer at a speed of 500 rpm Minutes, extract for 40 minutes, turn off the mixer; ②Second extraction: add 20°C water to the extraction tank after the first extraction and filtration, the mass ratio of slag to water is 1:0.5, start the mixer, and the speed is 500 rpm Minutes, extract for 40 minutes, turn off the mixer; ③The third extraction: add 20°C water to the extraction tank after the second extraction and filtration, the mass ratio of slag to water is 1:2, start the mixer, and the speed is 500 rpm minutes, extract for 40 minutes, and turn off the blender.

[0031] Step (2) Filtration: The extract obtained ...

Embodiment 2

[0035] Reclaim manganese from a certain electrolytic manganese waste residue, and the recovery steps of its manganese sulfate are as follows:

[0036] Step (1) Extraction: ①. First extraction: transport the electrolytic manganese waste slag to the extraction tank through a conveyor belt, add water at 85°C, the mass ratio of slag to water is 1:2, and start the mixer at a speed of 200 rpm Minutes, extract for 20 minutes, turn off the mixer; ②Second extraction: add 85°C water to the extraction tank after the first extraction and filtration, the mass ratio of slag to water is 1:1, start the mixer, and the speed is 200 rpm Minutes, extract for 20 minutes, turn off the mixer; ③The third extraction: add water at 85°C to the extraction tank after the second extraction and filtration, the mass ratio of slag to water is 1:1, start the mixer, and the speed is 200 rpm minutes, extract for 40 minutes, and turn off the blender.

[0037] Step (2) Filtration: filter the extract obtained from...

Embodiment 3

[0041] Reclaim manganese from a certain electrolytic manganese waste residue, and the recovery steps of its manganese sulfate are as follows:

[0042] Step (1) extraction: same as Example 1 or Example 1.

[0043] Step (2) Filtration: Filtrate the extracted extract to obtain filtrate and filter residue; the filtration is centrifugal filtration, the rotational speed of centrifugal filtration is 800-5000 rpm, and the optimum rotational speed is 1200-2000 rpm. The temperature is normal temperature.

[0044] Step (3) Purification: Same as Example 1 or Example 1.

[0045] Step (4) Concentration: Concentrate the purified extract obtained in step (3) into 38-42g / L manganese sulfate electrolyte through capacitive adsorption; the DC voltage of the capacitive adsorption concentration is 110V / m ~2×10 6 V / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com