System for treating laser coating

A coating and laser technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of difficulty in forming complex and fine patterns, slow coating processing speed, etc., to achieve optimized heat absorption, improved flow conditions, and high processing quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

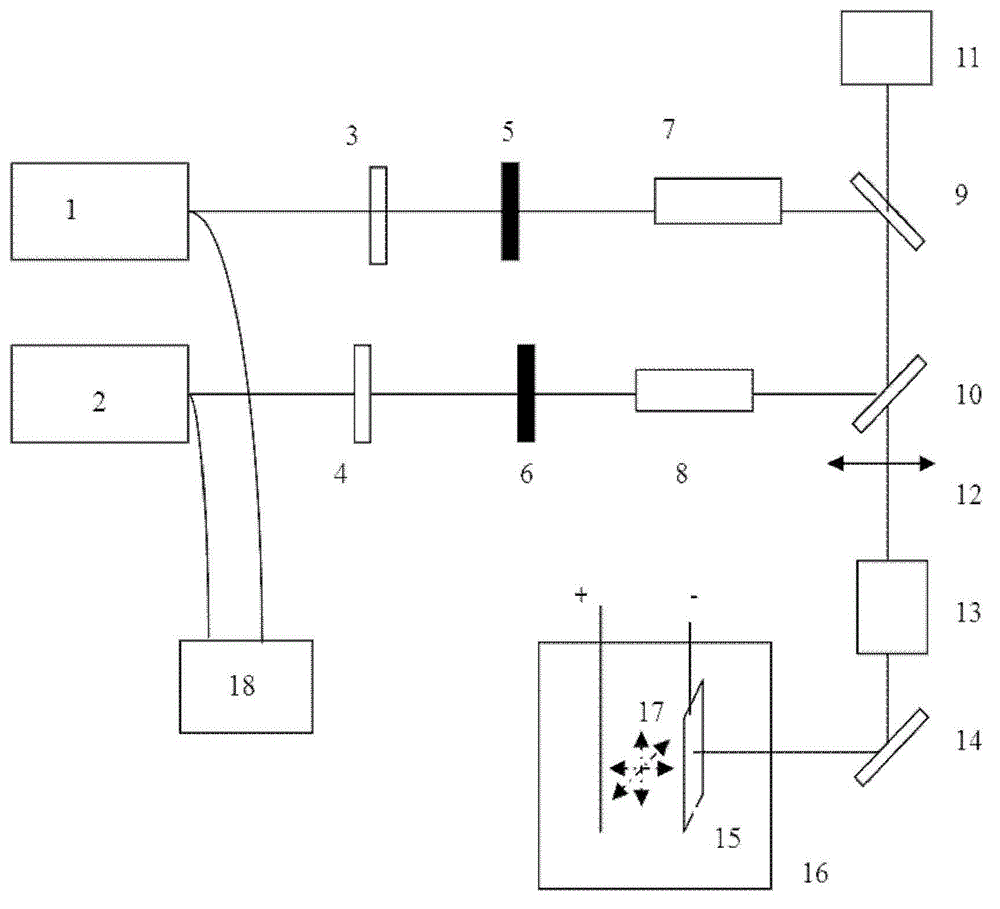

[0073] Example 1 is combined figure 1 The method for processing the laser coating provided by the present invention is described in detail.

[0074] The first pulse laser 1 is a Q-switched YAG frequency-doubled laser. The output laser beam has a wavelength of 532nm, an average power of 350mW, a pulse width of 100ns, a focused spot diameter of 500um, and an operating frequency of 200KHz; the second pulse laser 2 is Q-switched. The wavelength of the laser beam output by the YAG frequency doubled laser is 355nm, the average power is 200mW, the pulse width is 50ns, the spot diameter after focusing is 300um, and the working frequency is 200KHz.

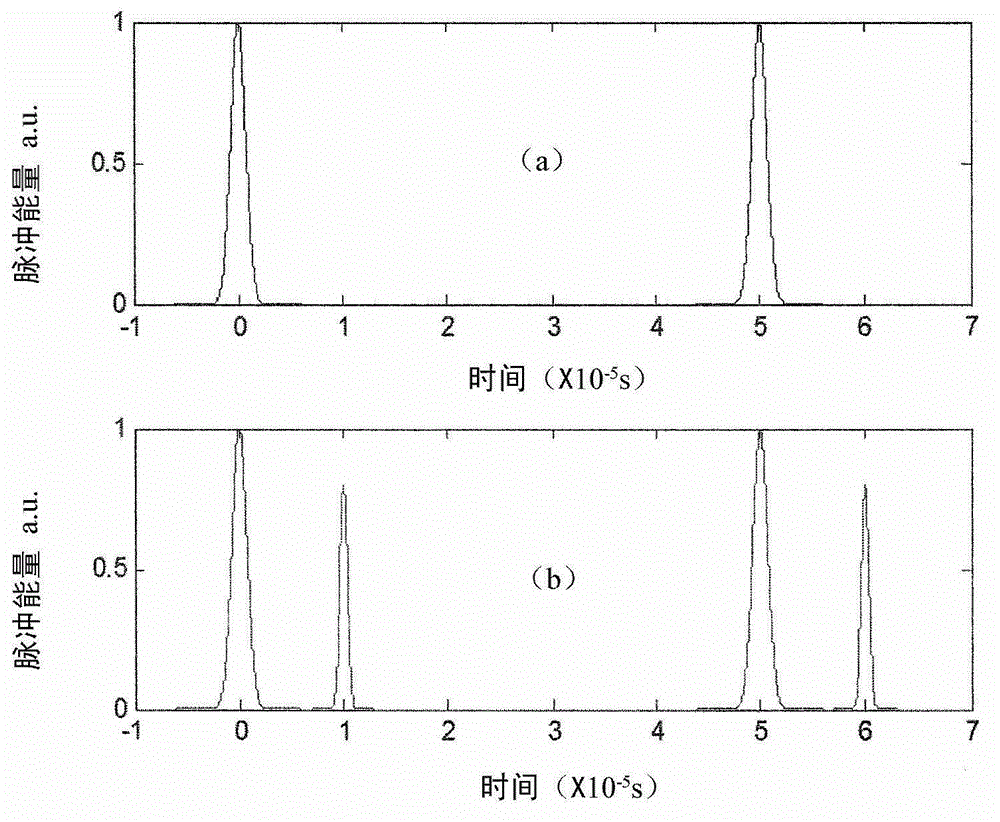

[0075] The first pulse laser 1 and the second pulse laser 2 are connected to a delay controller 18, and the delay controller 18 controls the interval between the first pulse emitted by the first pulse laser 1 and the second pulse emitted by the second pulse laser 2 by means of electrical modulation. There is a time delay which is 100ns. ...

Embodiment 2

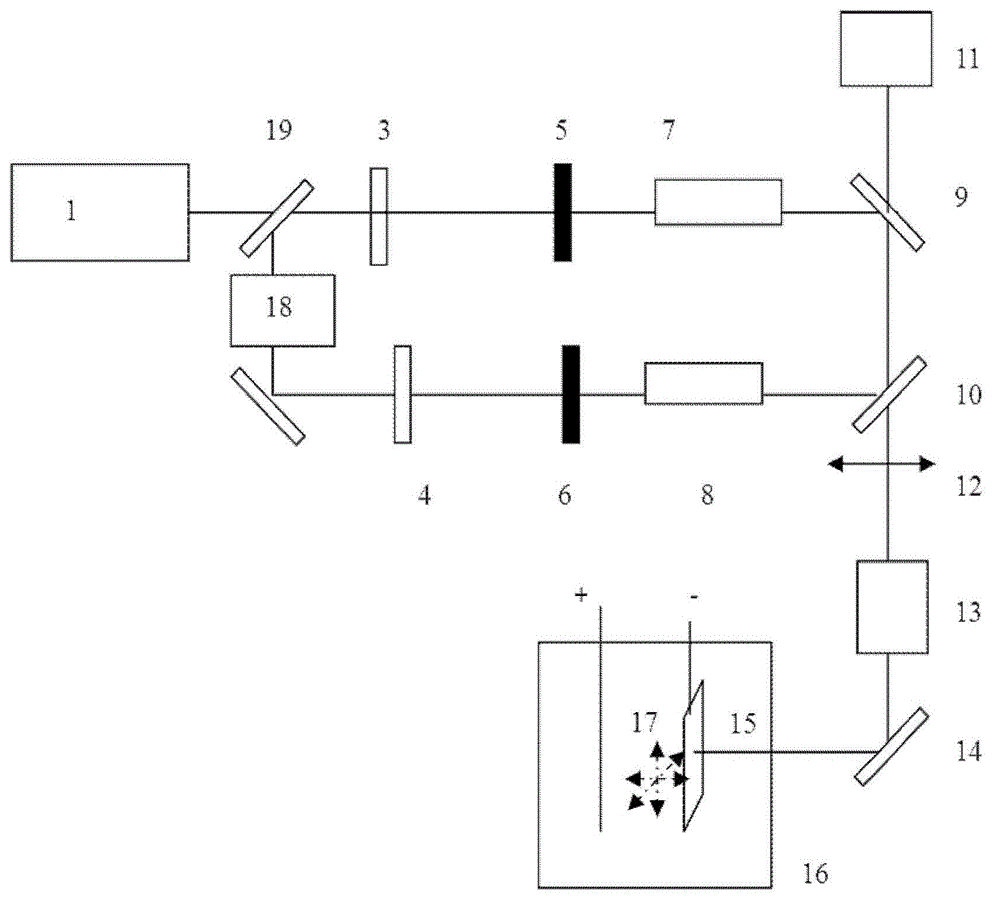

[0078] Example 2 is combined figure 2 The method for processing the laser coating provided by the present invention is described in detail.

[0079] The first pulse laser 1 is a Q-switched YAG frequency-doubled laser outputting a laser beam with a wavelength of 532nm, an average power of 350mW, a pulse width of 50ns, a spot diameter of 500um after focusing, and an operating frequency of 200kHz. Adopt the beam splitter 19 to split the second laser beam, utilize the spatial optical time retarder, adjust image 3 The relative positions of the two pairs of mirrors are such that the interval between the first laser pulse and the second laser pulse is 100 ns. Other operation steps are with embodiment 1

[0080] The invention provides a system for processing the laser coating, which realizes the fine processing of the laser coating. The laser fine processing method and system can be precisely controlled by laser coating processing. By using the laser beam with pulse and waveleng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com