Wallpaper with gradient effect and preparation method thereof

A technology of gradient effect and wallpaper, applied in the field of interior decoration, can solve the problems that wallpaper cannot meet individual requirements and high manufacturing cost, and achieve the effects of being suitable for large-scale production, saving raw materials, and simple and convenient preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

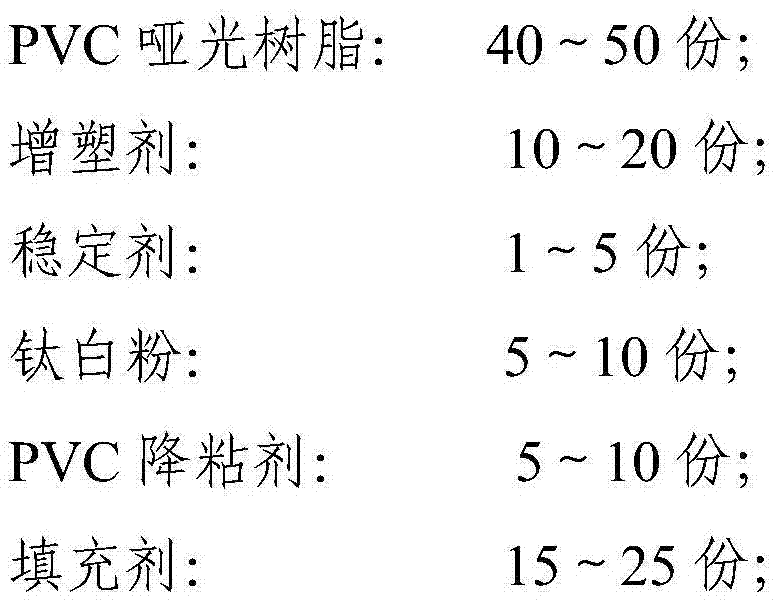

[0034] Matte PVC paste is as follows by weight percentage: PVC matte resin 45% (Shanghai Shixuan Chemical New Material Co., Ltd.), DOP plasticizer 17%, calcium-zinc composite stabilizer 2%, titanium dioxide 7%, G3H Adhesive 7% (French TOTAL company), calcium carbonate filler 22%. First, mix and stir PVC matte resin with DOP plasticizer, calcium-zinc composite stabilizer and G3H viscosity reducer, and then add titanium dioxide and calcium carbonate filler in turn under stirring to make a mixed paste.

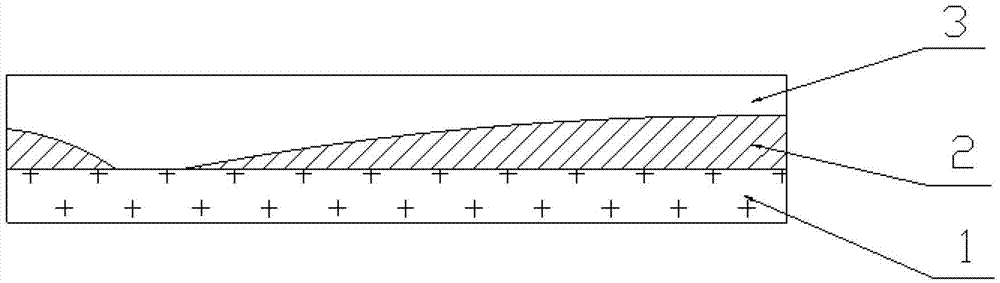

[0035] at 147g / m 2 Long-fiber non-woven paper is used as the substrate, and a layer of matte PVC paste is partially coated on the substrate with a rotary screen coater according to the pattern design, heated and plasticized at 150°C for 20s, and a semi-finished wallpaper is formed after cooling. Then use a rotary screen printing machine to print ink on the semi-finished wallpaper to form an ink printing layer, dry and cool to get a wallpaper with a gradient effect. The longitudi...

Embodiment 2

[0037] Matte PVC paste is as follows by weight percentage: PVC matte resin 50%, DOP plasticizer 11%, mercaptan octyl tin 4%, titanium dioxide 5%, G3H viscosity reducer 6%, CaCO 3 Filler 24%. First, mix and stir PVC matte resin with DOP plasticizer, octyltin mercaptide stabilizer and G3H viscosity reducer evenly, then add titanium dioxide and calcium carbonate in sequence under stirring to make a mixed paste.

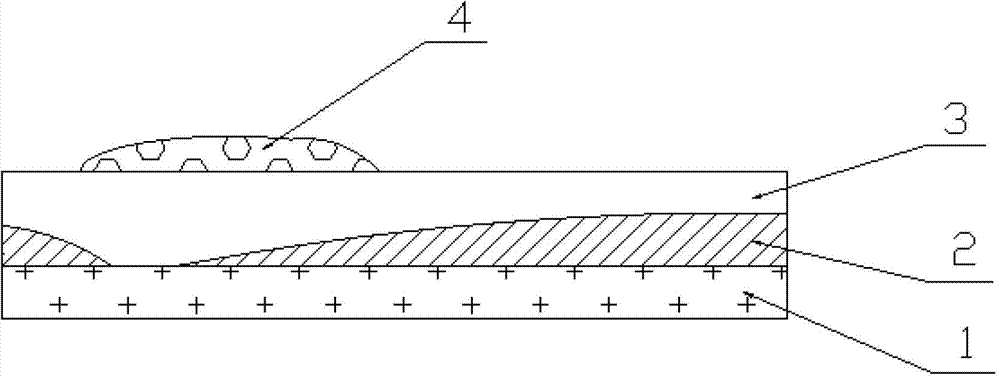

[0038] at 110g / m 2 Plain non-woven paper is used as the substrate, and a layer of matte PVC paste is partially coated on the substrate with a rotary screen coater according to the pattern design, heated and plasticized at 140°C for 25s, and a semi-finished wallpaper is formed after cooling. Then use a rotary screen printing machine to print ink on the semi-finished wallpaper to form an ink printing layer, dry and cool. Finally, a PVC partial overprint layer is formed on the ink printing layer, and the distribution of the overprint layer is complementary to the distribu...

Embodiment 3

[0040] Matte PVC paste is as follows by weight percentage: PVC matte resin 40%, DINP plasticizer 19%, calcium-zinc composite stabilizer 5%, titanium dioxide 10%, G3H viscosity reducer 9%, talcum powder filler 17% %. First, mix and stir PVC matte resin, DINP plasticizer, calcium-zinc composite stabilizer and G3H viscosity reducer evenly, and then add titanium dioxide and talcum powder filler in turn under stirring to make a mixed paste.

[0041] at 130g / m 2 Medium and long-fiber non-woven fabric is used as the substrate, and a layer of matte PVC paste is partially coated on the substrate with a rotary screen coater according to the pattern design, heated and plasticized at 170 ° C for 15 seconds, and a semi-finished wallpaper is formed after cooling. Then use a rotary screen printing machine to print ink on the semi-finished wallpaper to form an ink printing layer to obtain a wallpaper with a gradient effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com