Integral squeezing steel strand anchorage stay rope and manufacturing method thereof

A steel strand, extrusion technology, applied in structural elements, building components, building reinforcements, etc., can solve the problems of short service life, narrow application range, difficult thread processing, etc., to reduce processing difficulty and production costs. , The effect of reliable anchoring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

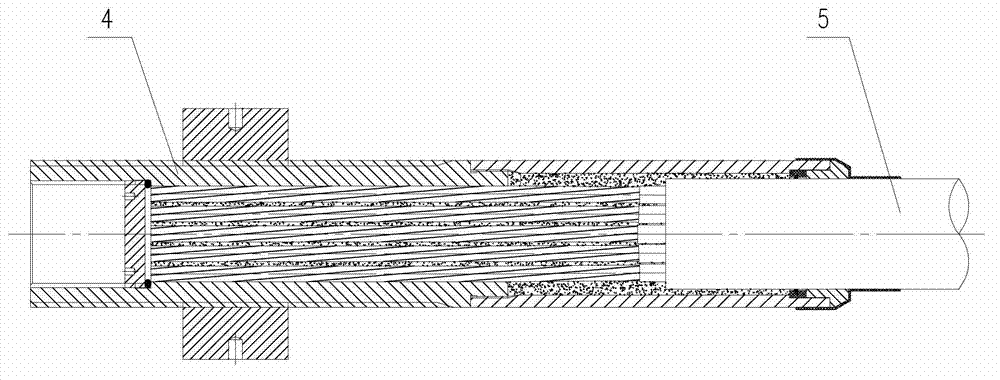

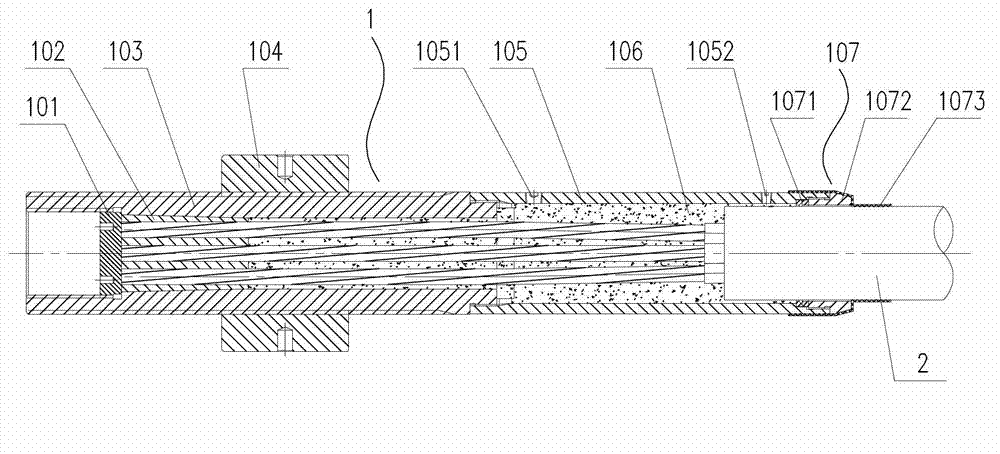

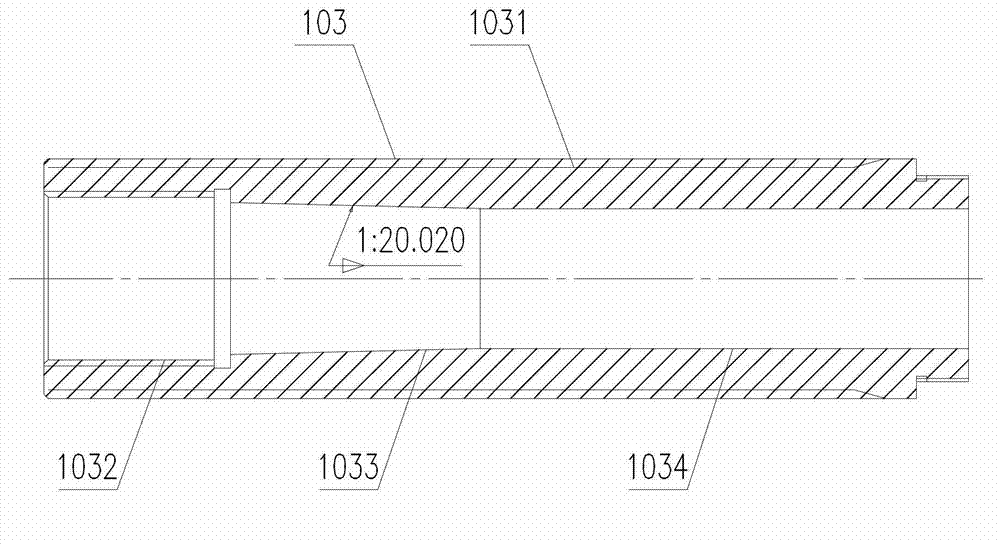

[0049] figure 2 Disclosed in is an integrally extruded steel strand anchor cable, comprising a steel strand finished cable 2 and an inner extruded cable anchor installed on the exposed steel strand 201 at the end of the steel strand finished cable 2 Tool 1, the internal extrusion type cable anchor 1 includes an extrusion anchor cup 103 with a long external thread 1031, an adjusting nut 104 installed on the extrusion anchor cup 103 and with a long internal thread, connected to Squeeze the sealing cylinder 105 at the end of the anchor cup 103, and a sealing device 107 is installed between the end of the sealing cylinder 105 and the finished steel strand cable 2, and one end of the extrusion anchor cup 103 is provided with an anti-loosening screw plug The threaded hole 1032 of 101, the other end is provided with the straight hole 1034 that is used to pass through whole bundle bare steel strand, and is provided with tapered hole 1033 between threaded hole 1032 and straight hole 1...

Embodiment 2

[0055] A method for manufacturing an integrally extruded steel strand anchor stay cable, comprising the following steps:

[0056] A. Processing of various parts and steel strand finished cables:

[0057] Each component of the inner extruded cable anchor 1 is processed according to the requirements, and the inner extruded cable anchor 1 includes an extruded anchor cup 103 with a long external thread 1031, a long internal thread with a long inner thread. Threaded adjusting nut 104, sealing cylinder 105, sealing device 107 and anti-loosening screw plug 101; at the same time, the finished steel strand cable 2 is made according to the requirements, and the protective layer of the steel strand at the end of the steel strand finished cable 2 is stripped off drop to form a bare steel strand 201;

[0058] B. assembly:

[0059] Screw the adjusting nut 104 on the extrusion anchor cup 103, and connect the extrusion anchor cup 103 with the sealing cylinder 105;

[0060] C. Wearing st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com