Seepage-proofing method of underwater reservoir and underwater reservoir with seepage-proofing function

A technology of underground reservoirs and functions, applied in water conservancy projects, large-capacity bulk material storages, marine engineering and other directions, can solve problems such as easy infiltration of underground reservoirs, and achieve the effect of protecting water quality and avoiding water infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

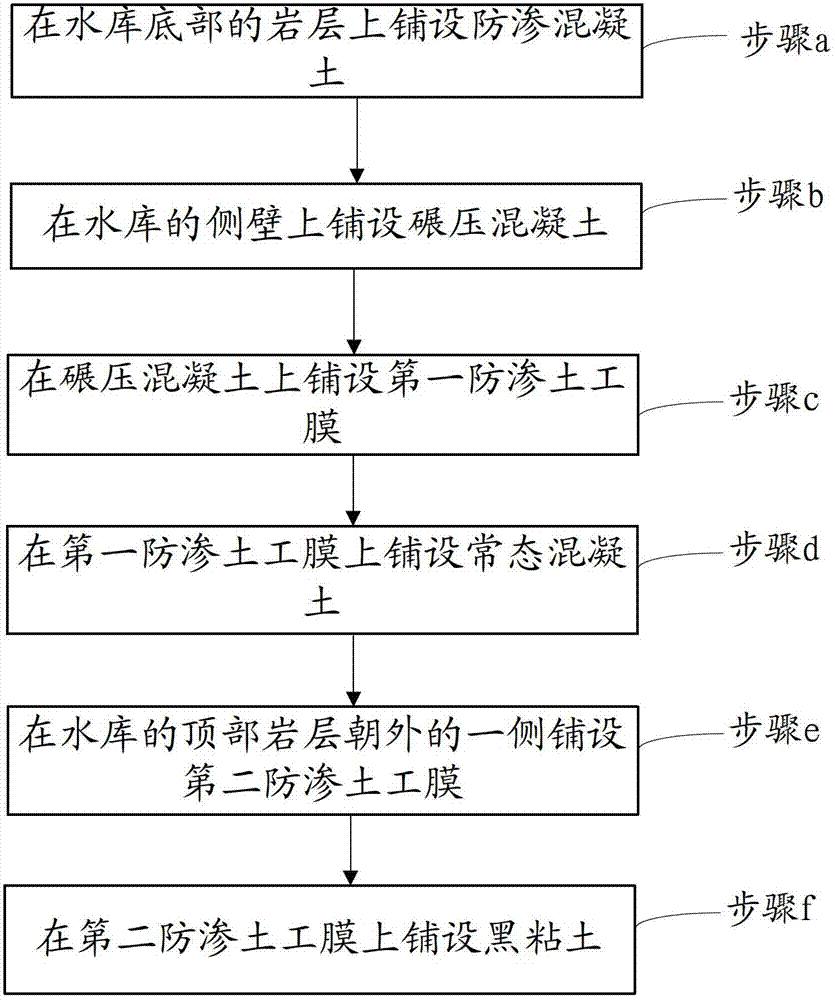

[0028] figure 1 The schematic flow chart of the anti-seepage method of the underground reservoir provided by the embodiment of the present invention, the present invention provides a kind of anti-seepage method of the underground reservoir, which includes the following steps:

[0029] Step a, laying anti-seepage concrete on the rock formation at the bottom of the reservoir. Among them, anti-seepage concrete refers to concrete added with anti-seepage materials such as chloride salt or triethanolamine.

[0030] In this step, the paving machine is used to lay the anti-seepage concrete, wherein the bottom rock formation of the underground reservoir can be analyzed, and the above-mentioned laying work can be done in the area where anti-seepage is required, instead of all areas at the bottom of the reservoir. The soil layer thickness of anti-seepage concrete paving is preferably 20-50cm, wherein 40cm is the best.

[0031] Step b, laying roller compacted concrete on the side wall o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com