Portable contact net wire abrasion measuring instrument

A catenary and portable technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of complex mechanical structure, circuit system and CCD image data processing, difficult and accurate data collection, and less data collection, so as to achieve friendly man-machine interface and measurement The effect of simple method and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

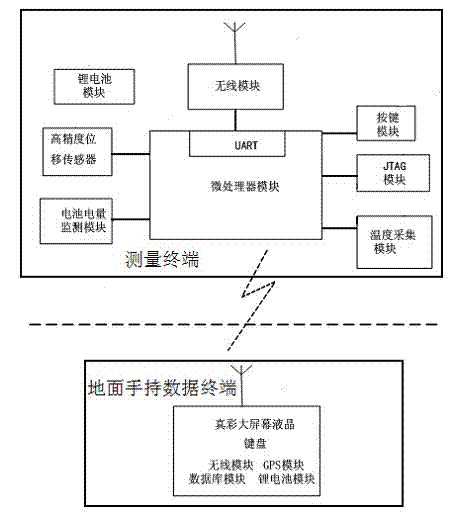

[0007] Such as figure 1 As shown, the present invention is realized in this way. It consists of two parts: a measuring terminal and a ground handheld data terminal. Information transmission is realized between the measuring terminal and the ground handheld data terminal in a wireless manner, wherein the measuring terminal is equipped with a high-precision displacement sensor. , wireless module, lithium battery module, battery power monitoring module, temperature acquisition module, JTAG module, button module and microprocessor module, the microprocessor module is connected with high-precision displacement sensor, battery power monitoring module, temperature acquisition module, JTAG module It is connected with the button module, and the microprocessor module is connected with the wireless module through the built-in UART; the ground handheld data terminal is equipped with a true-color large-screen LCD, a keyboard, a wireless module, a GPS module, a database module and a lithium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com