Non-contact type temperature measuring device and method for atomic gas chamber

An atomic gas chamber and temperature measurement technology, which can be used in measurement devices, heat measurement, thermometers, etc., which can solve the problems of atomic depolarization and limit the sensitivity of instruments, and achieve the effects of fast response, no production, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

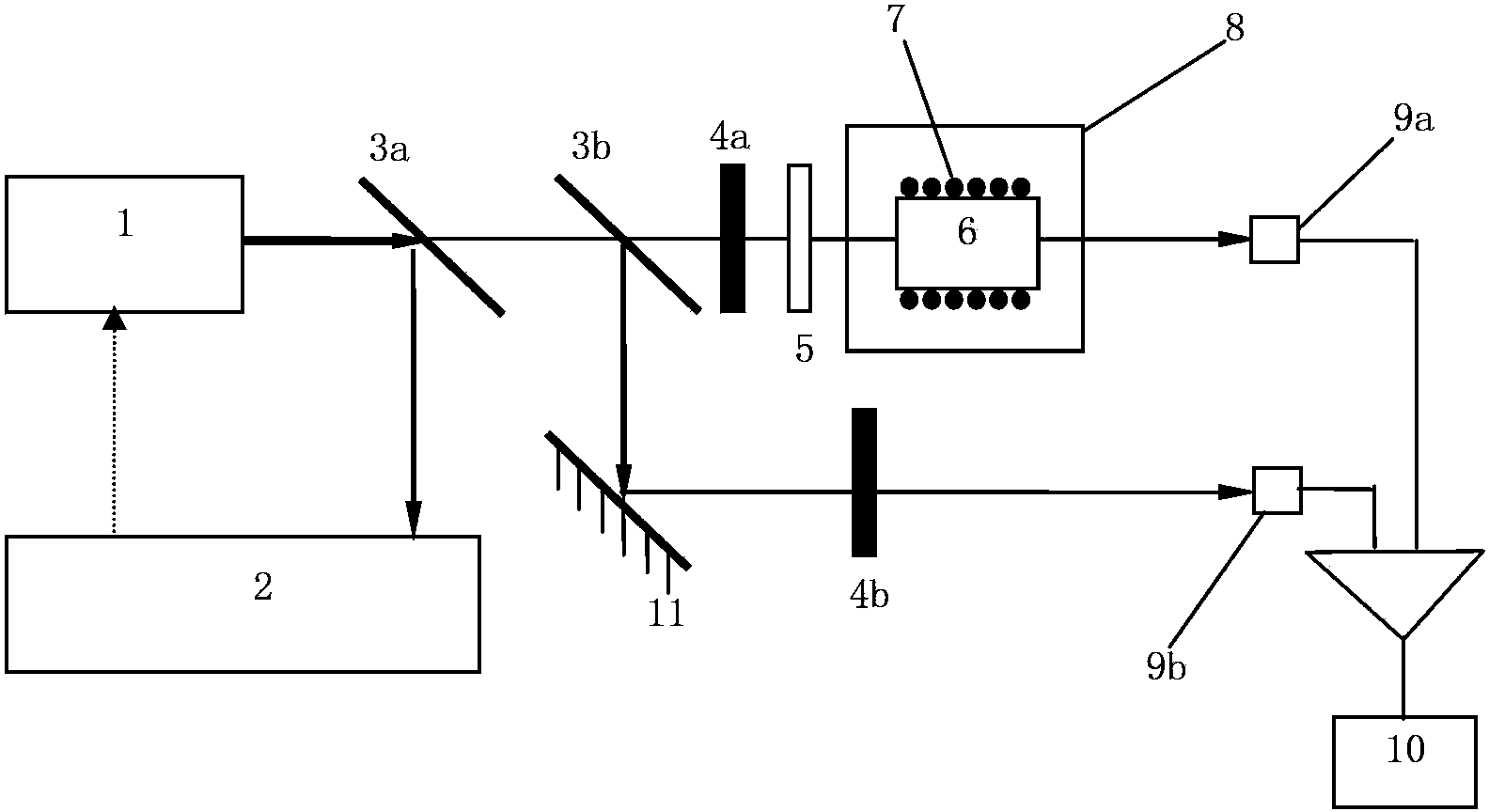

[0017] The cesium atom gas chamber 6 is heated by a tightly wound twisted pair 7 and placed in a magnetic shielding tube 8; the laser light source is a Littrow structure external cavity feedback semiconductor laser 1, and the sub-beam 3a splits a part of the output light to build a saturated absorption Spectrum 2 performs frequency stabilization control on the laser; then divides the reference light and the detection light into two parts through the sub-beam 3b, and adjusts the attenuator 4 to make the light intensity of the two beams equal; through the λ / 4 wave plate 5, the detection light becomes circularly polarized After passing through the cesium atom gas cell 6, the detection light and the reference light are respectively received by the detectors 9a and 9b, and output after subtraction and calculation.

[0018] By adjusting the temperature (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com