Method and system for measuring emissivity of high-temperature material

A technology of high-temperature materials and measurement methods, applied in measurement devices, analysis materials, material analysis by optical means, etc., can solve problems such as large measurement errors and difficulty in ensuring the synchronization of two measurements, so as to reduce error sources and improve measurement. Accuracy and convenience of testing, the effect of ensuring simultaneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

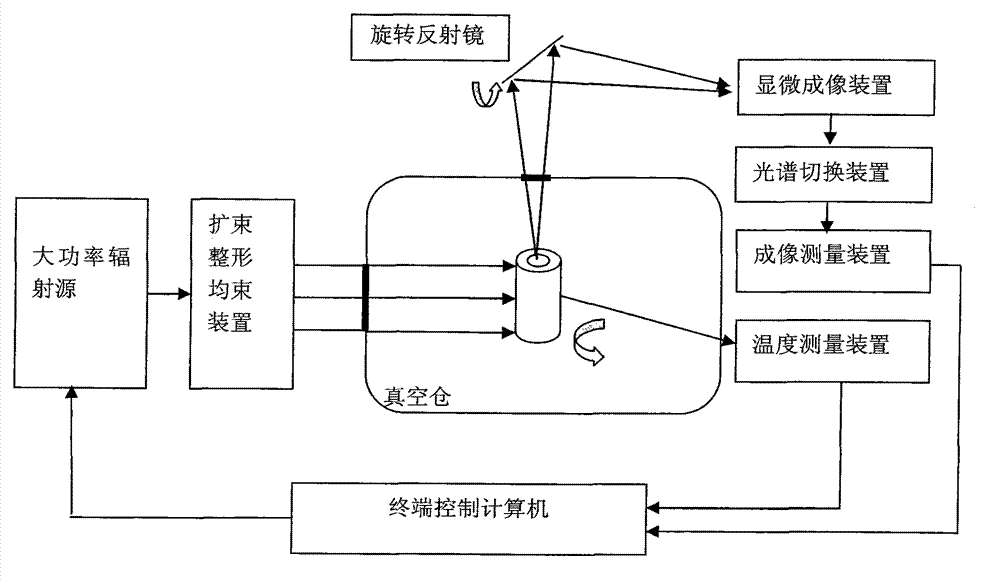

[0029] Below in conjunction with accompanying drawing, preferred embodiment of the present invention will be further described:

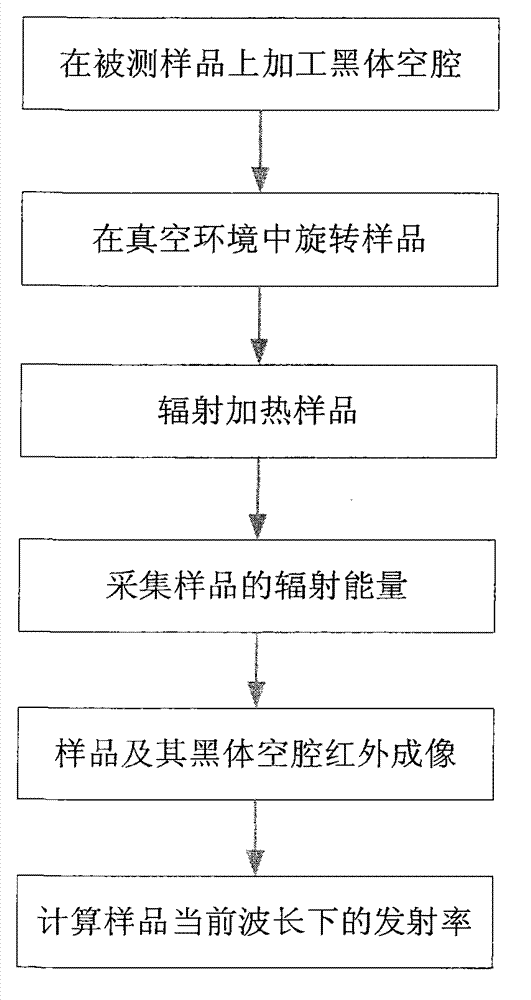

[0030] figure 1 Shown is the high-temperature emissivity imaging spectrum measurement flow chart of the material. The whole testing process can be divided into the following steps:

[0031] Step 1, processing a blackbody cavity on the sample to be tested. First, the sample to be tested is processed into a cylindrical shape, and a hole is opened on one side of the cylinder. The geometric size of the hole meets the condition of forming a black body cavity effect.

[0032] Step 2, rotate the sample in a vacuum environment. Place the sample to be tested vertically in the vacuum chamber and fix it, with one end of the opening facing upwards, so that the sample to be tested is kept rotating at a constant speed in the horizontal plane during the test.

[0033] Step 3, radiative heating of the sample. Radiation energy is used to irradiate the measured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com