Warping-resistant optical thin film, preparation method thereof and display device using optical thin film

A technology for optical films and display devices, applied in optics, nonlinear optics, instruments, etc., can solve the problems of forming wavy lines, easy to produce warping, etc., and achieve the effects of easy operation, low coating shrinkage, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the anti-warping optical film provided by the invention comprises the following steps:

[0042] (1) Prepare the upper diffusion coating coating solution: in the mixing tank, add 100 parts by weight of glue, 70-100 parts by weight of diffusion particles, 0.01-5% of additives, solvent, and stir for 1-4 hours. Then add curing agent and stir for 0.5-1 hour;

[0043] (2) Prepare the lower diffusion coating coating solution: in the mixing tank, add 100 parts by weight of glue, 50-100 parts by weight, or 1-20 parts by weight of diffusion particles, 0.01-5% of additives, solvents , stirred for 0.5-4 hours, then added curing agent, stirred for 0.5-1 hours;

[0044] (3) Apply the upper diffusion coating coating solution prepared in step (1) to the upper surface of the transparent substrate, and bake at 80-120°C for 1-30 minutes;

[0045] (4) Coating the lower diffusion coating coating solution prepared in step (2) on the lower surface of the transparen...

Embodiment 1

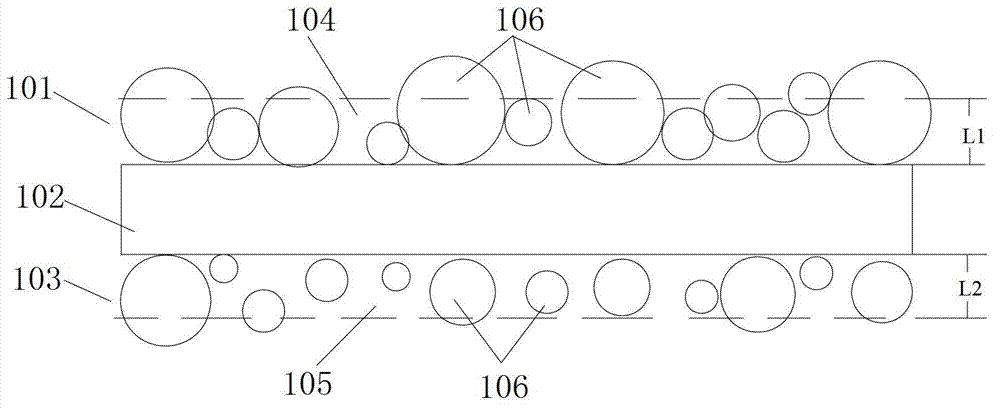

[0057] Prepare the anti-warping optical film provided by the invention according to the above method, such as figure 1 As shown, the anti-warping optical film includes a transparent substrate 102, the transparent substrate is made of PET, the thickness is 100um, and the heat shrinkage rate is 0.2%-1.5%. The upper surface of the transparent substrate is provided with an upper diffusion coating 101, the upper diffusion coating is acrylic resin, the upper diffusion particles are arranged in the coating, the upper diffusion particles include organic particles and inorganic particles, and the upper diffusion adhesive layer 104 is in parts by weight is 100 parts by weight, and the part by weight of the upper diffusion particles is 75 parts by weight. The lower surface of the transparent substrate is provided with a lower diffusion coating 103, the lower diffusion coating is acrylic resin, and the lower diffusion coating is provided with lower diffusion particles, the lower diffusion...

Embodiment 2

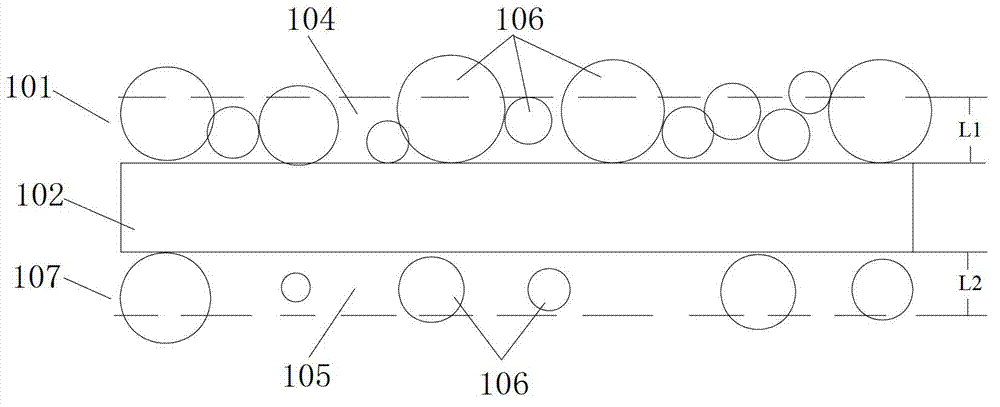

[0059] Prepare the anti-warping optical film provided by the invention according to the above method, such as figure 2 As shown, the transparent substrate 102 is PET with a thickness of 38um and a thermal shrinkage rate of 0.2%-1.5%. The upper diffusion coating 101 is made of acrylic resin, and the upper diffusion particles contained are organic particles and inorganic particles. The weight of the upper diffusion adhesive layer The parts are 100 parts by weight, and the parts by weight of the upper diffusion particles are 100 parts by weight. The protective coating 107 is made of acrylic resin, and the lower diffusion particles are organic particles with a particle size of 3um-20um. The weight part of the lower diffusion layer is 100 parts by weight, and the weight part of the diffusion particles is 20 parts by weight. The weight of the lower diffusion particles is 0.2 times that of the upper diffusion particles, and the thickness of the protective coating 107 is 2 um thicker...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com