Lens calibration system of employing imaging technology and calibration method thereof

A calibration system and calibration method technology, which are applied to the lens calibration system and calibration field using imaging technology, can solve the problems of high labor cost, complicated procedures, and time-consuming technology, and achieve the effect of reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

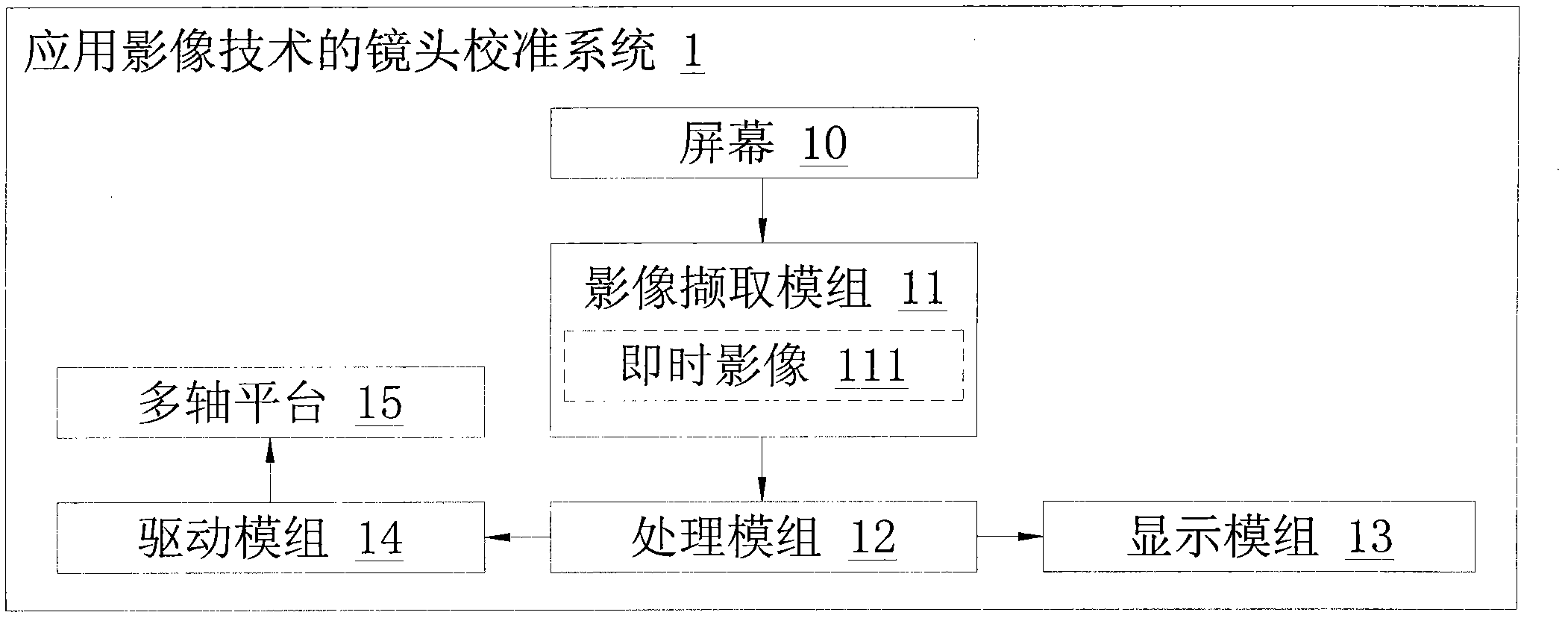

no. 1 example

[0050] According to the first embodiment, the present invention also provides a second embodiment for further illustration.

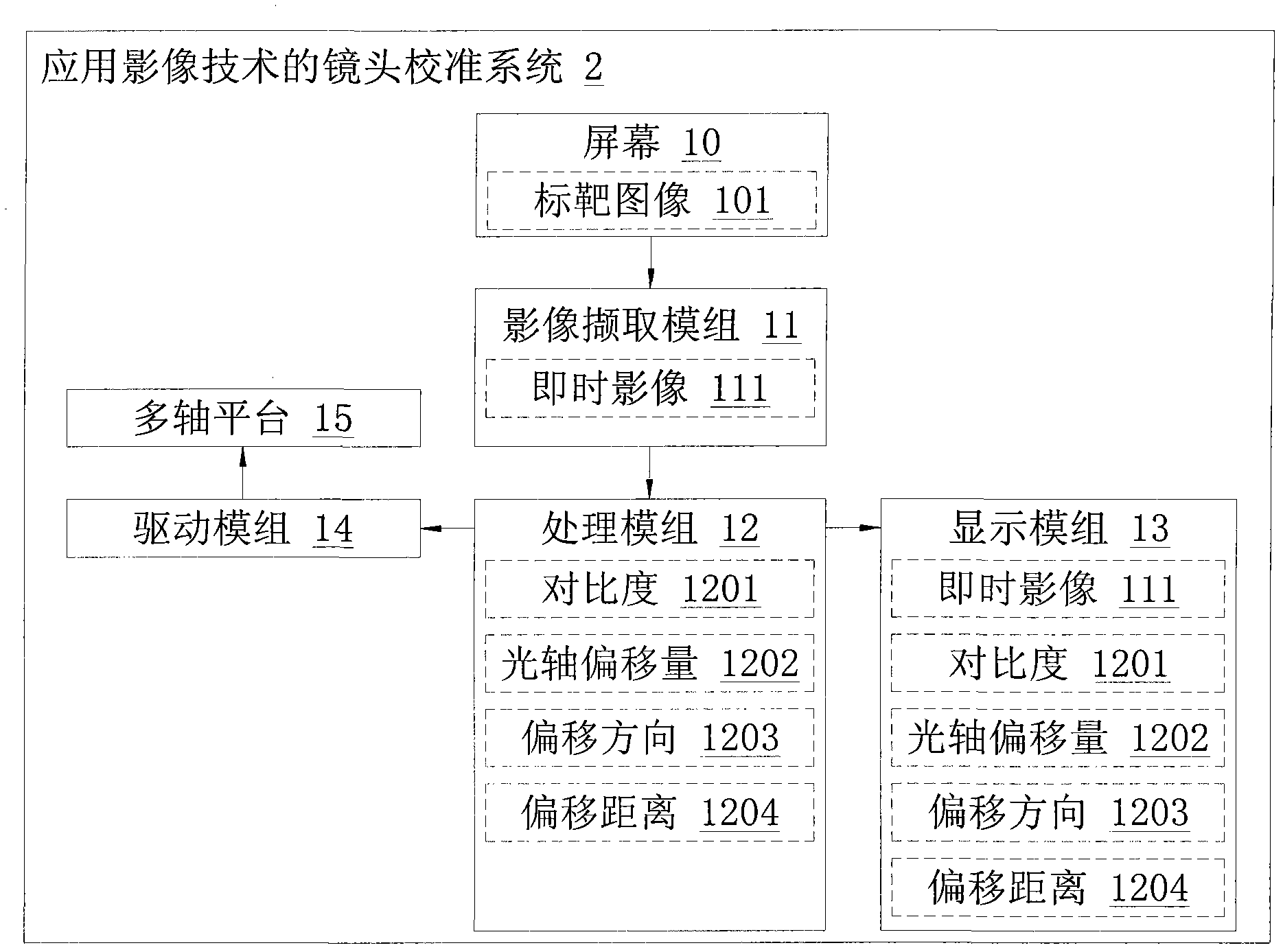

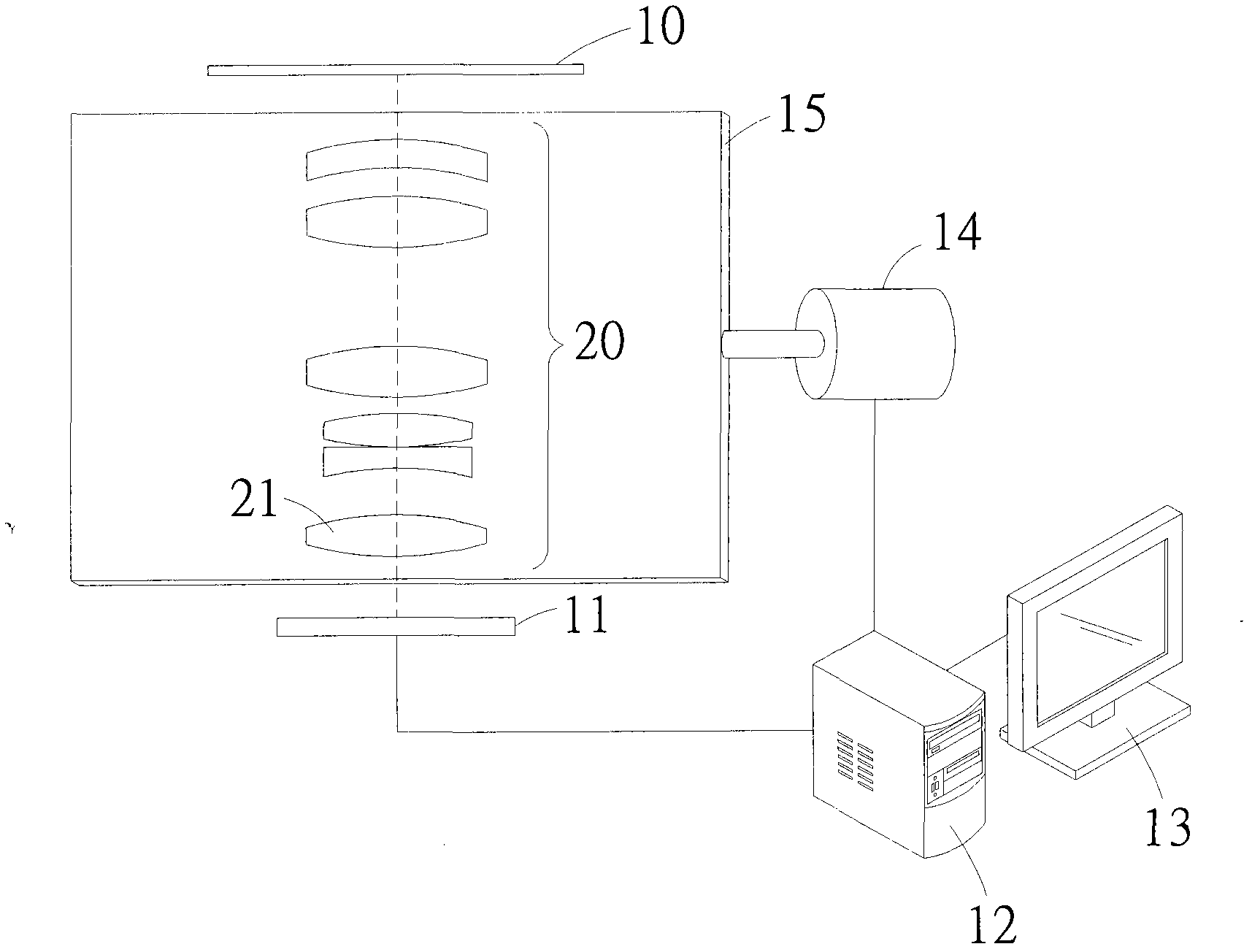

[0051] Please refer to Figure 5 , Which is a block diagram of the second embodiment of the lens calibration system using imaging technology of the present invention. Such as Figure 5 As shown, the lens calibration system 3 applying image technology may include a screen 10, an image capturing module 11, a processing module 12, a display module 13, a driving module 14 and a multi-axis platform 15. The screen 10 can be used to display a target image 101. The image capturing module 11 may include a photosensitive element, such as a complementary metal oxide semiconductor element or a charge coupled element. The image capturing module 11 can capture a target image 101 through a lens to obtain a real-time image 111. Wherein, the lens is a lens to be calibrated, which may include an auto-focus lens group. The processing module 12 is electrically connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com