Servo driving method on basis of electric cylinder

A technology of servo drive and servo drive, applied in the field of servo drive, can solve the problems of low control precision and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

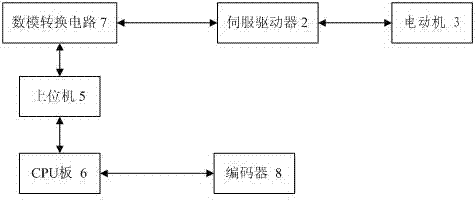

[0023] The specific steps of a servo drive method based on an electric cylinder are:

[0024] The first step is to build a servo drive system based on the electric cylinder

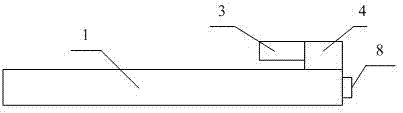

[0025] The servo drive system of the electric cylinder includes: electric cylinder 1, servo driver 2, motor 3, reducer 4, upper computer 5, CPU board 6, analog-to-digital conversion circuit 7, encoder 8; reducer 4 is placed in the electric cylinder 1 The outer side is fixedly connected with the electric cylinder 1, the internal gear of the reducer 4 is fixedly connected with the electric cylinder 1, and the encoder 8 is placed inside the electric cylinder 1 and connected with the electric cylinder 1 bearing. The encoder 8 is connected to the CPU board 6 with a two-way cable, the CPU board 6 is connected to the upper computer 5 with a two-way plug-in board, the upper computer 5 is connected to the analog-to-digital conversion circuit 7 with a bi-directional plug-in board, and the analog-to-digital conversi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com