Replaceable ceramic or glass type sealed electrical penetrating piece assembly

A technology for electrical penetrations and ceramic sealing, which is applied in the fields of sealing, nuclear power generation, and reduction of greenhouse gases. The effect of not being easy to age and decompose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

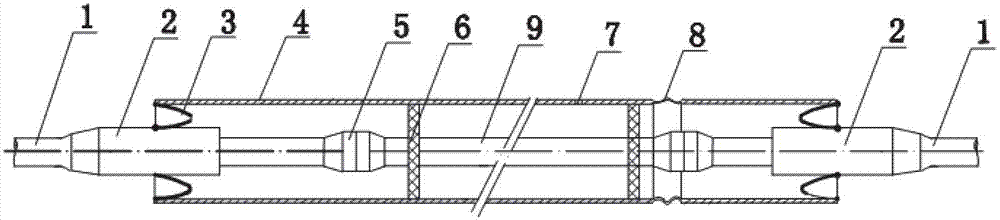

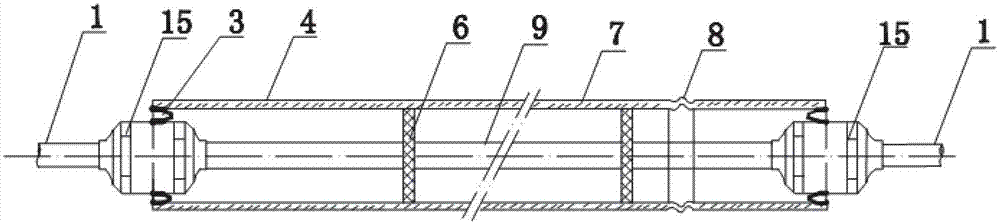

[0023] Example: Combined figure 1 In this embodiment, a replaceable ceramic or glass-type sealed electrical penetration assembly, the penetration assembly includes a circular tube-shaped stainless steel assembly housing 4, the insulated conductor 9 is coaxially arranged in the assembly housing 4, and the two ends of the insulated conductor are provided with The ceramic seals 2 are conductors 1 outside the two ceramic seals, and the elastic metal transition ring 3 is used for sealing between the outer wall of the ceramic seal 2 and the end inner wall of the component housing 4 .

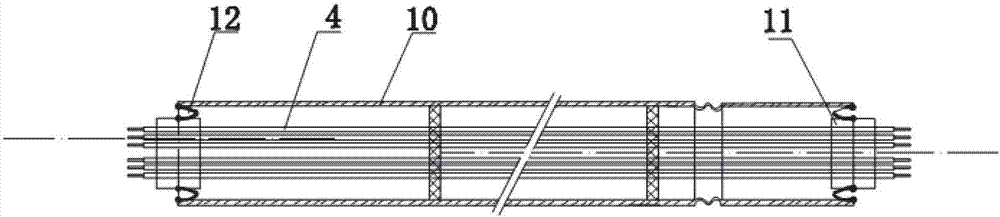

[0024] combine image 3 , a plurality of through-piece components are coaxially arranged in a circular tube-shaped stainless steel through-piece body 10, and end plates 11 are arranged at both ends of the through-piece body, and an elastic metal The sealing ring 12 is sealed.

[0025] combine Figure 4 , the two ends of the component housing 4 pass through the end plate 11, and there is a sealing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com