High-power high-speed permanent magnet generator rotor surface-mounting type fixing permanent magnet structure and method

A permanent magnet generator and permanent magnet technology, which is applied in the direction of magnetic circuit shape/style/structure, manufacturing stator/rotor body, magnetic circuit rotating parts, etc., can solve problems that affect work safety and permanent magnets are not firmly fixed, etc. To achieve the effect of safe work, firm fixation and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

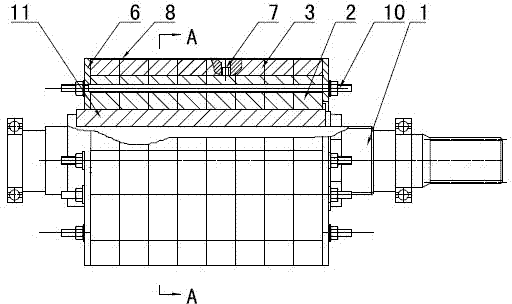

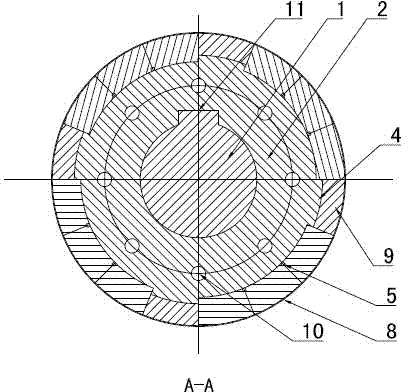

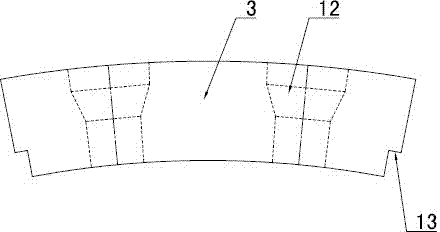

[0023] Figure 1~4 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~4 The present invention will be further described.

[0024] Refer to attached Figure 1~2 : The high-power high-speed permanent magnet generator rotor surface-mounted fixed permanent magnet structure includes a motor shaft 1, and the motor shaft 1 is covered with a rotor core 2 formed by axially stacking multiple rotor punches. 2. There is a motor shaft hole with a keyway in the center. The motor shaft 1 traverses the motor shaft hole and is connected with the rotor core 2 through the key 11 in the keyway. The outer raised pole spacers 4, four pole spacers 4 divide the outer surface of the rotor core 2 into 4 permanent magnet areas, and the surface of each permanent magnet area is evenly distributed along the axial direction with two poles for positioning the permanent magnets 3 Boss 5, the surface of the permanent magnet area is pasted and fixed by high-stren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com