Cleaning system

A cleaning and cleaning brush technology, applied in the field of cleaning systems, can solve problems such as electrostatic damage, damaged materials, and difficulty in foreign matter adsorption, and achieve the effect of preventing electrostatic damage and excellent maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

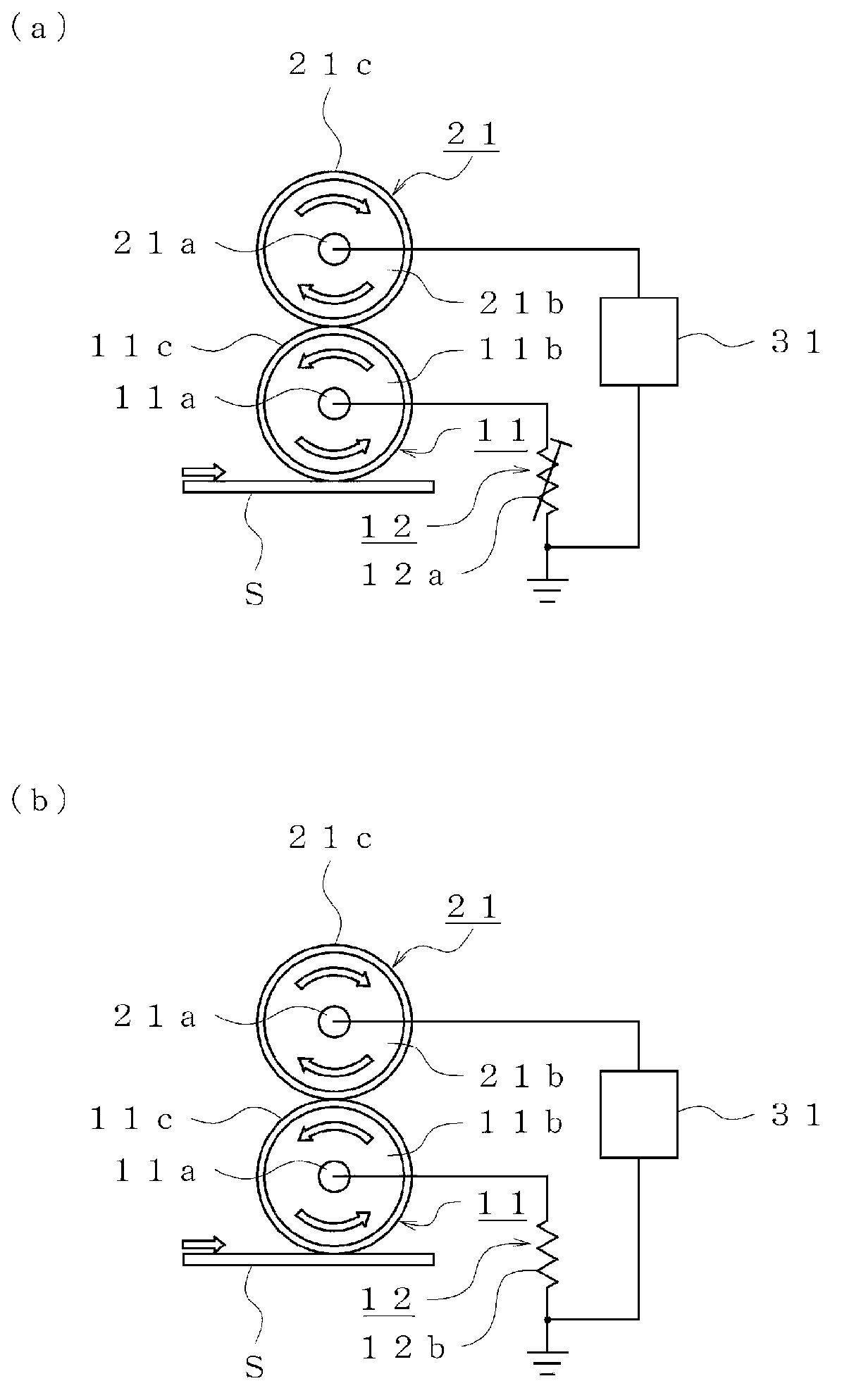

Embodiment 1

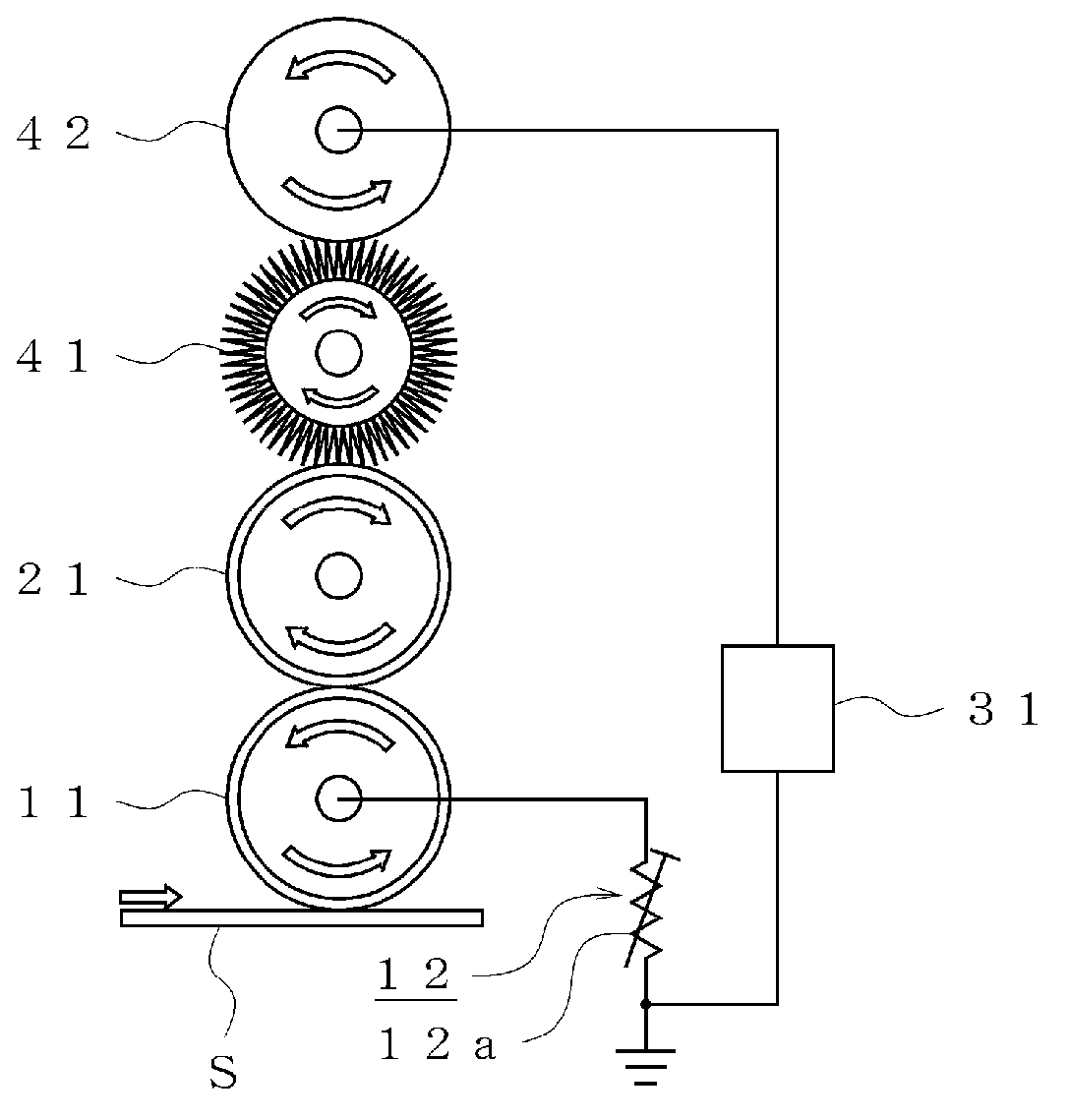

[0103] exist figure 2 In the cleaning system shown, the cleaning roller 11 and the transfer roller 21 held by an insulating member (not shown) are brought into contact with each other and rotated at a peripheral speed of 5 m / min. The ground line is provided through the variable resistor 12a. In addition, the external power supply 31 is connected to the metal roller 42 provided via the cleaning brush 41 to the transfer roller 21 . The cleaning brush 41 is set so as to face the transfer roller 21 and rotate in the direction opposite to the driving rotation direction, and the metal roller 42 is set so as to face the cleaning brush 41 and rotate in the driving rotation direction.

[0104] In the above state, the surface potential of each member with respect to the change in the resistance value of the variable resistor 12 a was measured using a surface potentiometer (Model 341B manufactured by Trek Corporation).

[0105] Table 1

[0106]

[0107] From this measurement resul...

Embodiment 2

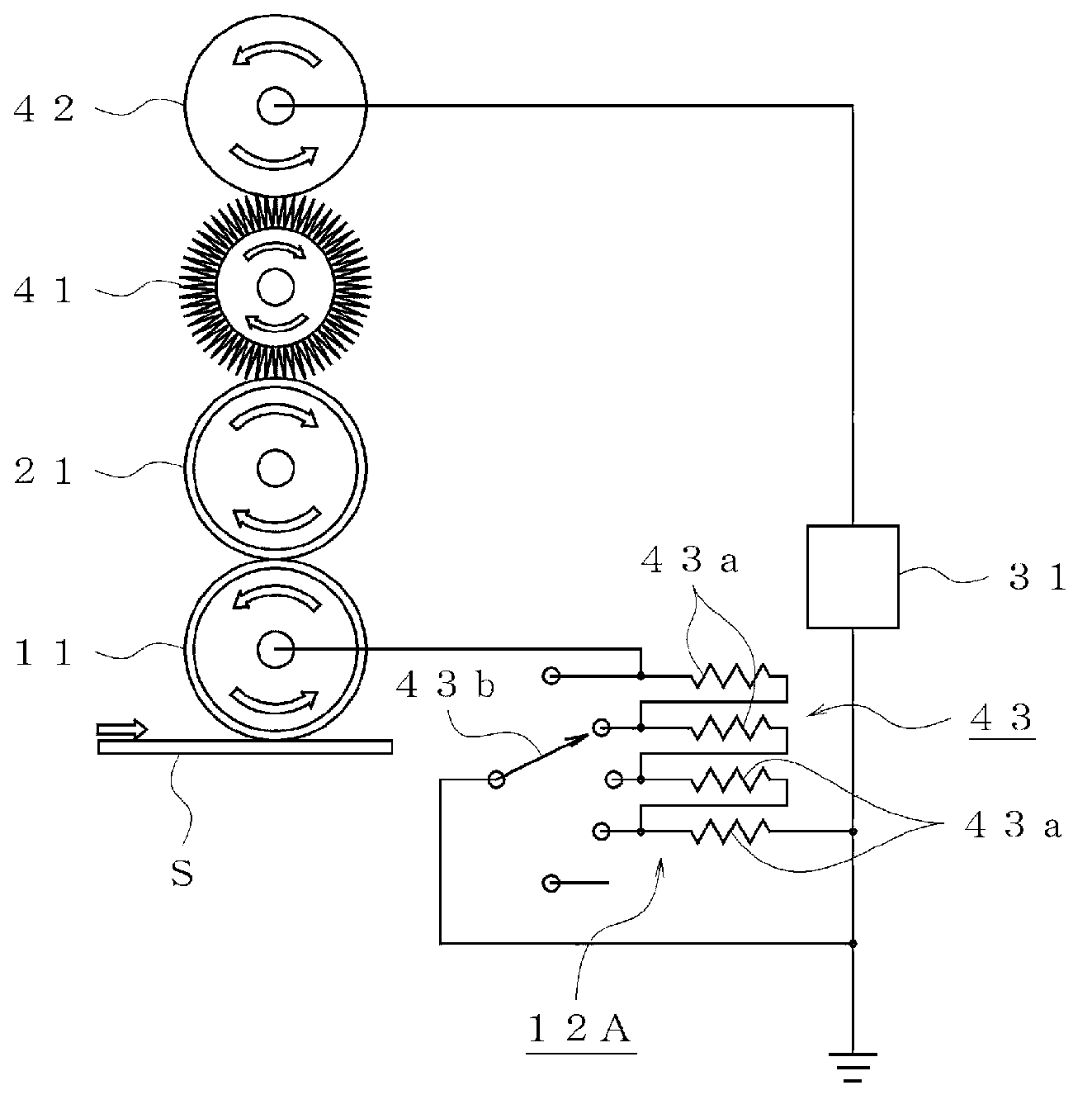

[0129] exist Figure 13 In the cleaning system shown, the cleaning roller 11 and the transfer roller 21 held by an insulating member (not shown) are brought into contact with each other, and rotated at a peripheral speed of 5 m / min. On the core metal of the cleaning roller 11 A ground line is provided through a first voltage stabilizing circuit 13A (zener diode 13 a ) constituted by a Zener diode 13 a (Zener diode). In addition, with respect to the transfer roller 21, a cleaning brush 41 and a metal roller 42 are provided, and a second voltage stabilizing circuit 15A (zener diode 15a) is provided between the cleaning roller 11 and the core metal of the transfer roller 21. A third voltage stabilization circuit 16A (zener diode 16a) is provided between the printing roller 21 and the core metal of the cleaning brush 41, and a fourth voltage stabilization circuit is provided between the cleaning brush 41 and the core metal of the metal roller 42 17 (variable resistor 17a). The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com