Method and device for producing a highly selectively absorbing coating on a solar absorber component, and solar absorber having such a coating

A solar energy absorption and absorption film technology, applied in solar thermal power generation, solar thermal devices, coatings, etc., can solve the problems of high equipment cost and lack of economy, and achieve the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

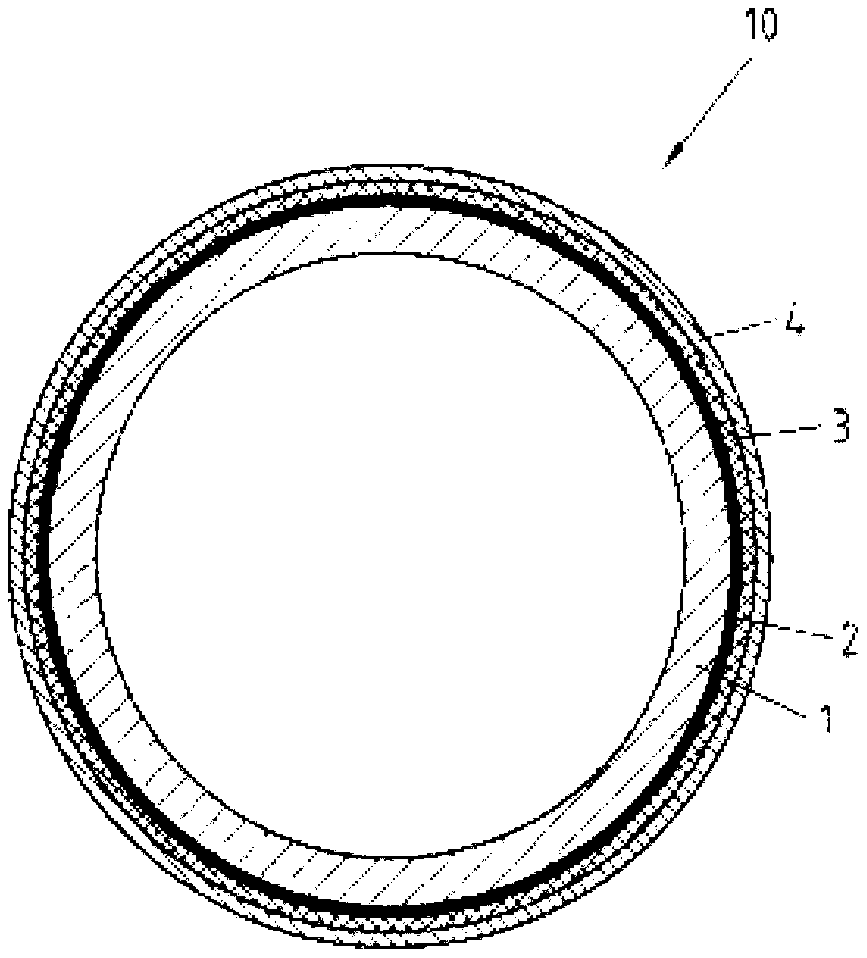

[0045] figure 1 A cross-section of an absorber tube 10 with a selectively absorbing film for a bowl-shaped trough collector is depicted. Here, in order to achieve visual clarity, the thickness of each film and the thickness of the substrate material are not marked.

[0046] figure 1 The absorption pipe 10 in the present invention comprises a steel pipe 1, and the steel pipe 1 is provided with a layer of film 2 which helps to increase the adhesion on its outer surface. Here, preferably, the film 2 is an aluminum or steel film, wherein the film 2 is preferably deposited on the steel pipe surface by electrolysis. Since this adhesion-promoting film 2 is completely free of pores, it is preferred here that the electrolytically deposited film has a minimum thickness of 8-10 microns.

[0047] However, for some steel pipes with poor surface quality, the steel pipe 1 will have pores on its surface. In this case, the following scheme is meaningful: First, a metal film (such as nickel)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com