Preparation method and application of oil-water curing agent

A curing agent, oil-water technology, applied in the direction of application, fertilizer mixture, layered/coated fertilizer, etc., can solve the problems of greater harm to the planting environment, poor slow-release effect, and environmental hazards, and achieve short curing time and toughness High, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 A kind of preparation method of oil-water curing agent

[0041] This embodiment is an oil-water curing agent, and the preparation method is carried out in sequence according to the following steps:

[0042] (11) Put 0.5L formaldehyde in a container, adjust the pH to 7.0~8.0 with an equal volume of ammonia water in a hot water bath, and obtain A1;

[0043] (12) Add urea to A1, the molar ratio of urea to formaldehyde is 0.3:1, stir well to get B1;

[0044] (13) Heat B1 to 80°C and react for 30 minutes to obtain C1;

[0045] (14) Add 3.55 g of enhancer soluble starch (the mass ratio of soluble starch to urea is 0.03:1) to C1 at a rate of 12 g / min, and keep warm for 30 minutes to obtain D1;

[0046] (15) Add 5.92g of water resistant mineral oil (the mass ratio of mineral oil to urea is 0.05:1) dropwise to D1, and keep it warm for 25 minutes to obtain E1;

[0047] (16) When E1 is stored at 40°C, a liquid oil-water curing agent can be obtained. The curing temp...

Embodiment 2-5

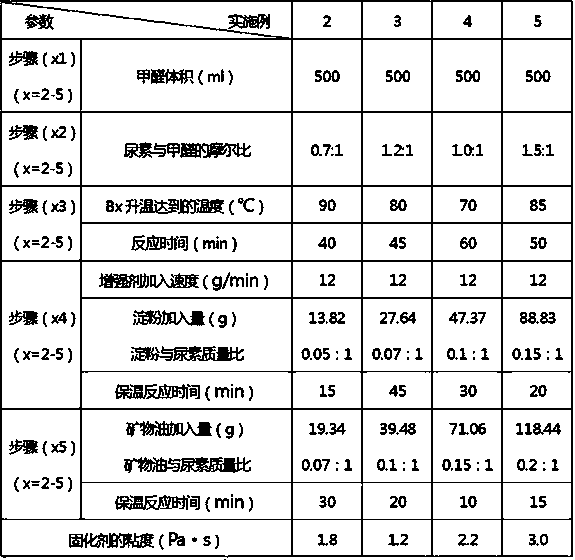

[0049] The preparation method of embodiment 2-5 curing agent

[0050] Examples 2-5 are respectively a preparation method of a curing agent, and the specific preparation steps are similar to those of Example 1, the only difference being that the corresponding technical parameters in the preparation process are different, see Table 1 below for details.

[0051] Table 1 Technical parameter table

[0052]

[0053] The preparation process of Examples 2-5 is simple, the process is easy to control, there is no free formaldehyde in the prepared product, the preparation is safe, the cycle is short, and the cost is low. The prepared curing agent is easy to form a film and has high toughness. After film formation, the curing time Short, 0.5-2.0min at room temperature can be cured, the film layer is uniform, no cracking, good integrity, good water resistance, and has a good slow-release effect.

Embodiment 6

[0054] Embodiment 6 Characterization of oil-water curing agent

[0055] The present invention has carried out relevant characterization experiment to the oil-water curing agent prepared in embodiment 1-5, and specific result is as follows:

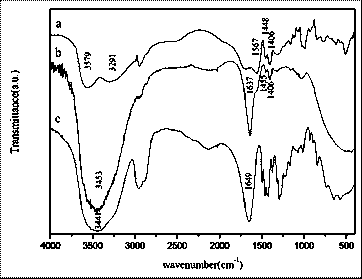

[0056] (1) Infrared characterization results

[0057] figure 1 Infrared spectrum of oil-water curing agent, by figure 1 As can be seen, the product prepared in embodiment 1 is at 1567 cm -1 and 1488 cm -1 C=O stretching vibration absorption peak in urea-formaldehyde product C, 1406 cm -1 It is the C-N stretching vibration absorption peak, indicating that the urea-formaldehyde product C has undergone a chemical reaction with starch. 3579 cm in the picture -1 The vibration peak is the effect of intermolecular hydrogen bond between mineral oil and starch, which is the same as 3291cm -1 The stretching vibration absorption peak intensity of the hydroxyl group in starch is significantly weaker than that, indicating that the mineral oil an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com