Compound type numerically-controlled machine tool

A CNC machine tool and composite technology, applied in the direction of large fixed members, metal processing machinery parts, clamping, etc., can solve problems such as excessive smoke, large work site, and larger work site

Inactive Publication Date: 2013-02-20

深圳市博利昌智能装备有限公司

View PDF7 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although plate automatic blanking and cutting machines and plate automatic drilling machines are widely used in the field of mechanical processing, traditional semi-automatic steel plate cutting machines occupy a large work space, and it is impossible to combine drilling, cutting and typing and other functions are integrated, and several processing methods need to use different kinds of machine tools, which not only requires multiple machine tools, but also takes up a larger work site, which increases the cost and processing hours, and will be generated during the processing process. a lot of smoke

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

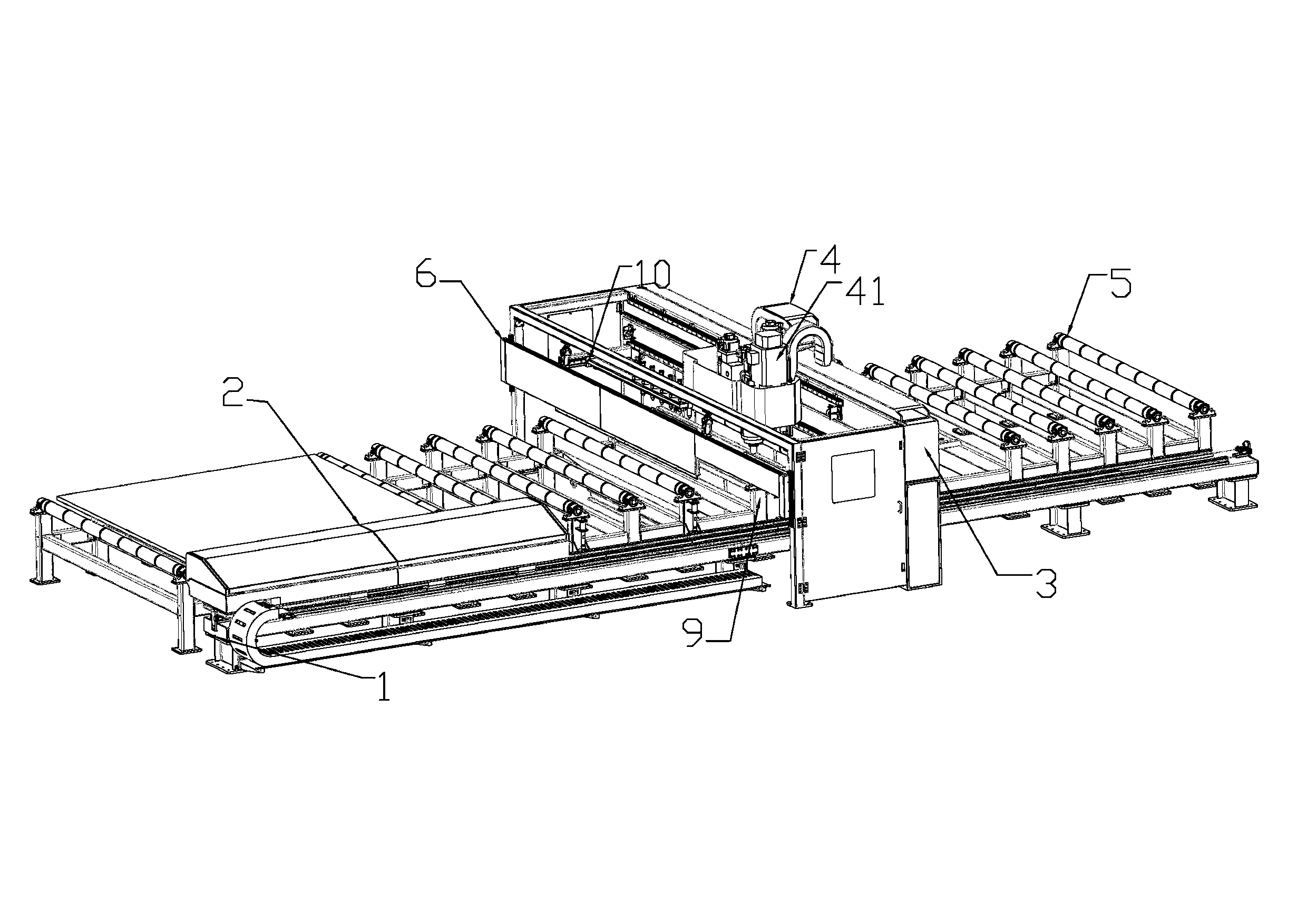

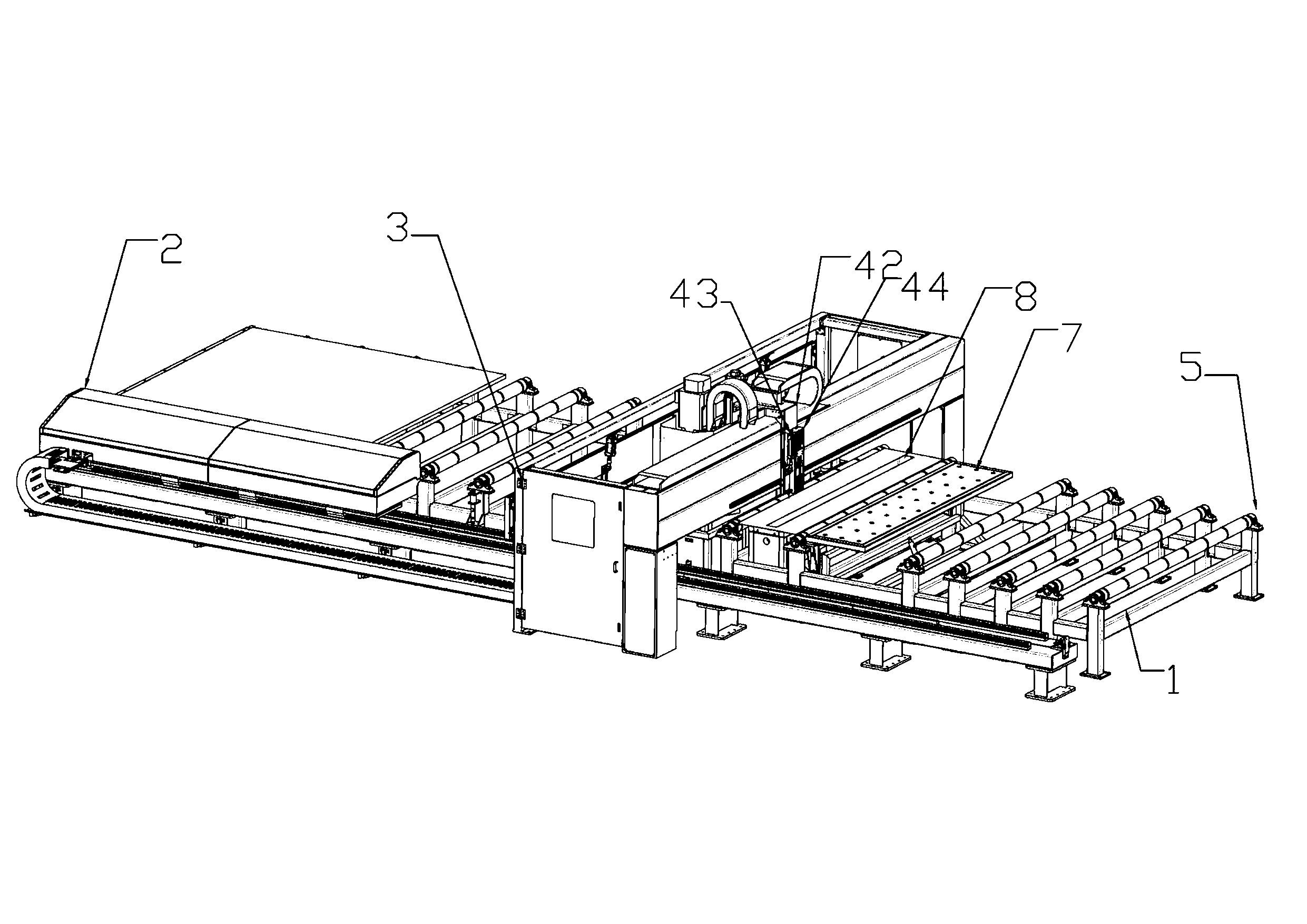

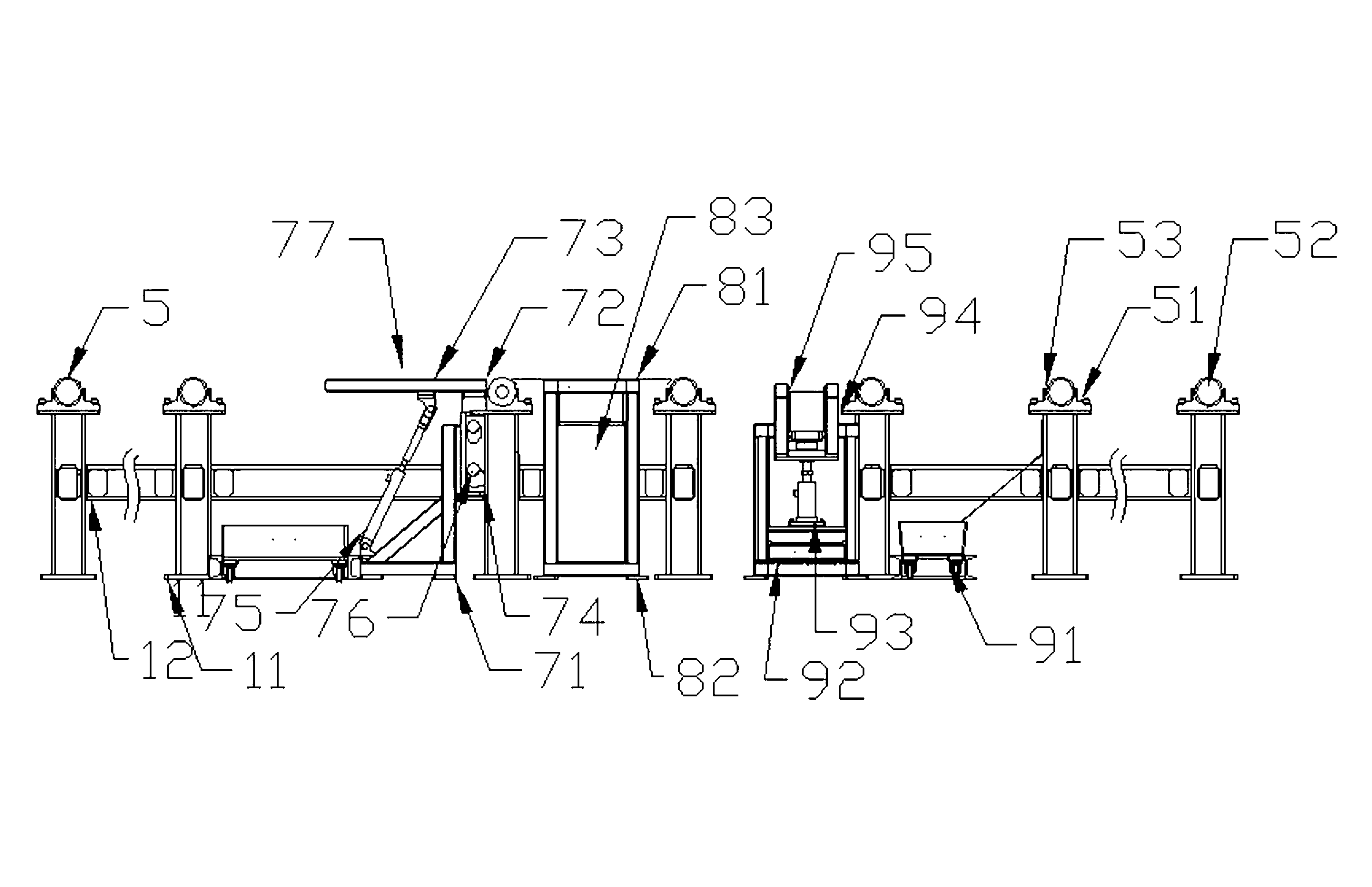

The invention relates to a compound type numerically-controlled machine tool. The compound type numerically-controlled machine tool mainly comprises a machine tool base, an X-axis platform, a Y-axis platform and a Z-axis platform, wherein a drilling mechanism, a typing mechanism and a cutting mechanism are arranged on the Z-axis platform; the drilling mechanism comprises a motor base which is arranged on the X-axis platform, a main shaft motor which is arranged on the motor base, a drilling main shaft which is driven by the main shaft motor, and a cutting tool which is arranged on the drilling main shaft; the typing mechanism and a cutting platform are arranged on a mounting base plate; the cutting mechanism comprises a screw rod, a cutting linear guide rail which is matched with the screw rod, and a servo motor which drives the screw rod to work; a cutting head is arranged on the screw rod and achieves high-speed cutting action under the driving of the screw rod; and the typing mechanism comprises a cylinder and a pneumatic typing head which is arranged on a linear guide rail, and the typing mechanism performs typing action through the cooperation of the cylinder and a typing linear guide rail. The compound type numerically-controlled machine tool can realize a plurality of functions, so that the used amount of machine tools is reduced, only a small amount of work places are needed, the cost and the processing time are reduced, and generated smog can be removed.

Description

technical field [0001] The invention relates to the field of mechanical processing equipment, in particular to a multifunctional composite numerical control machine tool. Background technique [0002] At present, there is a CNC drilling and cutting machine on the market, which is composed of machine, electricity, gas and hydraulic composite CNC processing equipment, computer control system, mechanical or hydraulic power system, servo feeding mechanism, tool library, tool selection system, peripheral programming system, etc. . Although plate automatic blanking and cutting machines and plate automatic drilling machines are widely used in the field of mechanical processing, traditional semi-automatic steel plate cutting machines occupy a large work space, and it is impossible to drill, cut and type. and other functions are integrated, and several processing methods need to use different kinds of machine tools, which not only requires multiple machine tools, but also takes up ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23P23/04B23Q3/155B23Q11/00B23Q1/25B23Q7/00

Inventor 曹爱国

Owner 深圳市博利昌智能装备有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com