Antistatic agent made from silver nanowire and functional carbon nano tube (CNT) and preparation method

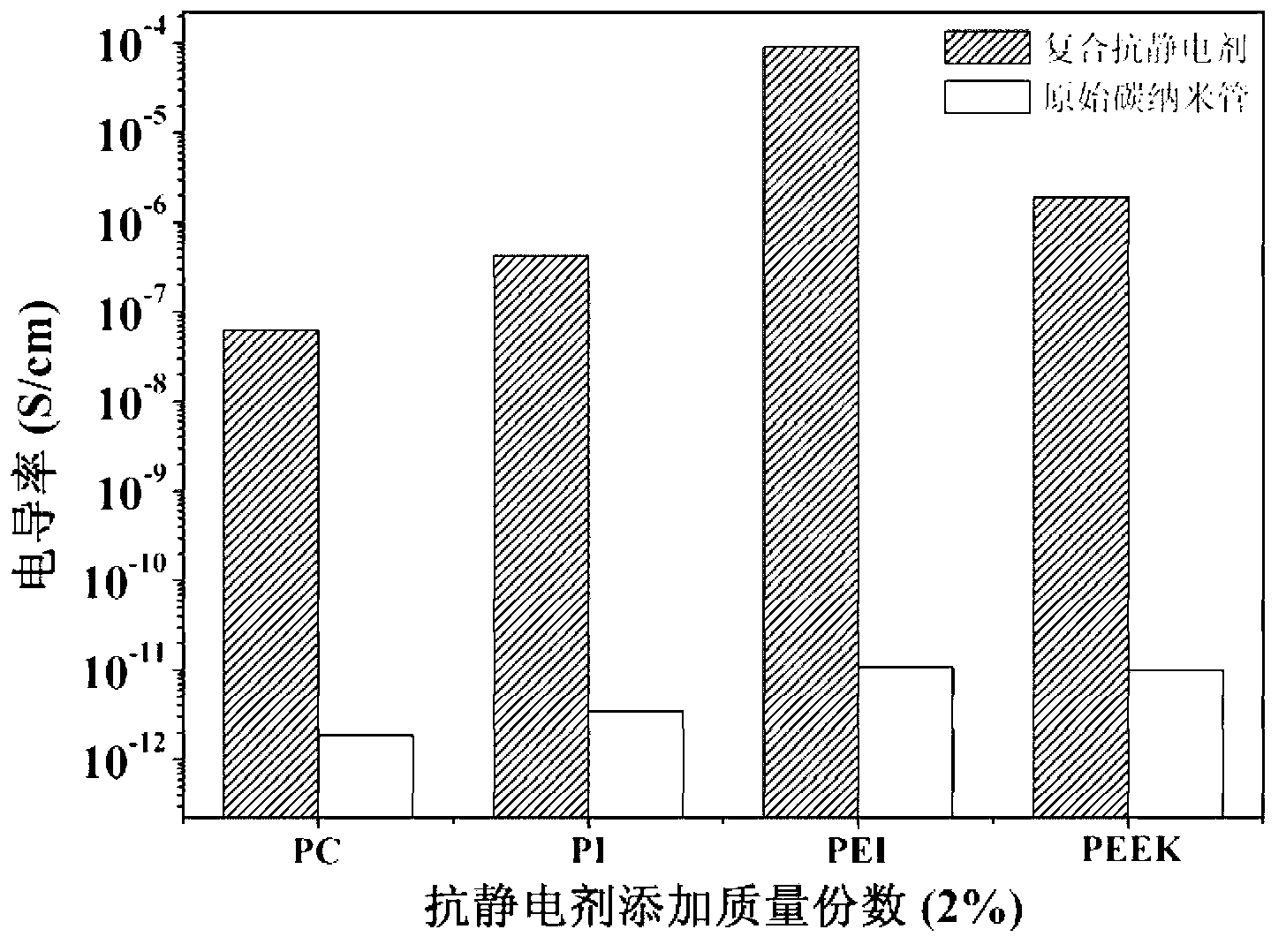

A carbon nanotube and antistatic agent technology, applied in the field of silver nanowire functionalized carbon nanotube antistatic agent, can solve the problems of reducing the addition amount of carbon nanotubes, poor dispersibility, influence, etc., to improve the synergistic enhancement effect, overcome the The effect of high contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

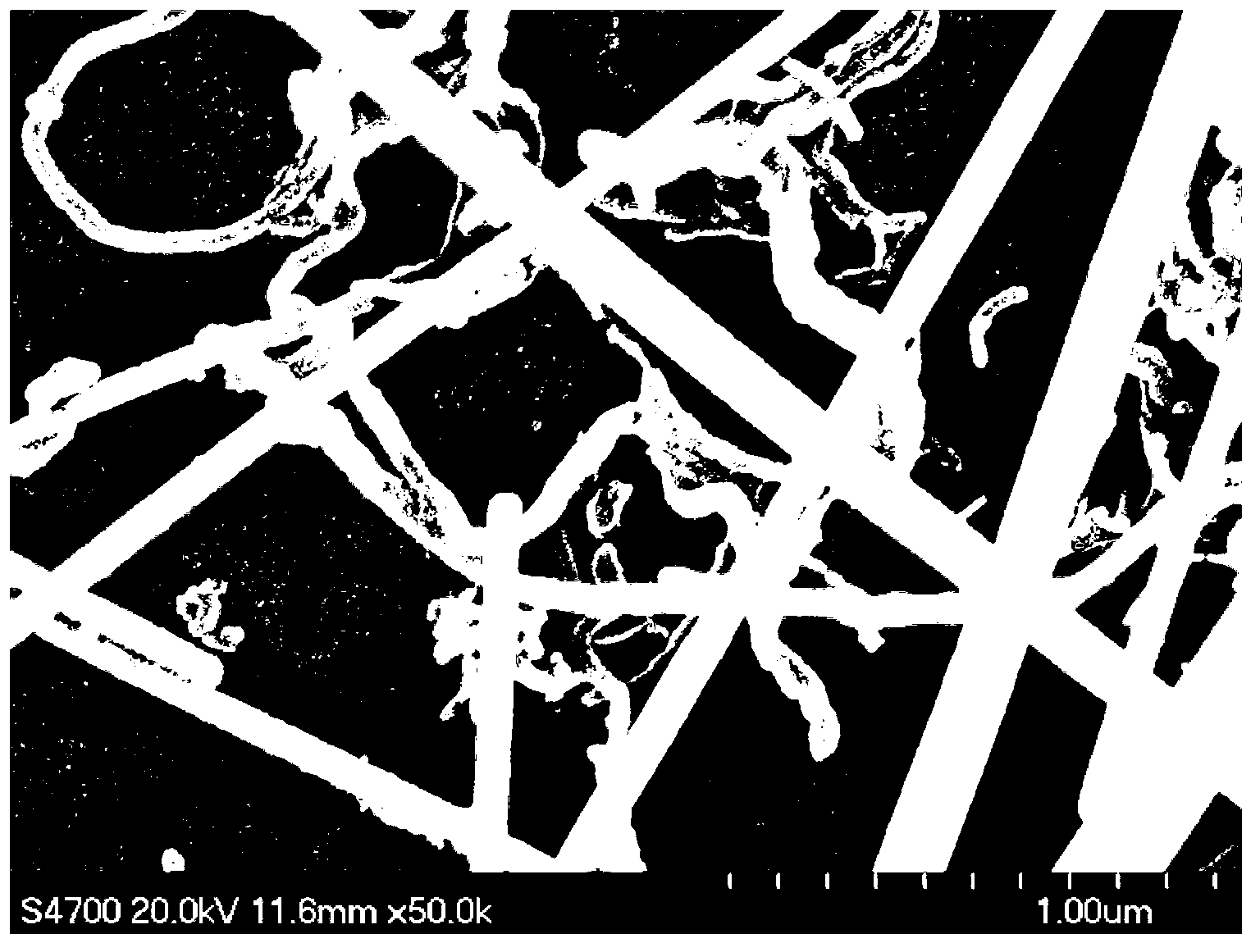

[0016] The first step: disperse the acidified carbon nanotubes into N,N dimethylformamide and sonicate for 2 hours, then add thioglycolic acid and catalytic equivalent of 4-dimethylaminopyridine, react at 85°C for 24 hours, then filter, wash and dry to obtain mercapto Functionalized carbon nanotubes, wherein acidified carbon nanotubes: N,N dimethylformamide: thioglycolic acid = 1g: 150ml: 0.1g.

[0017] Step 2: Ultrasonic disperse the mercaptolated carbon nanotubes into ethylene glycol, add a solution of platinous chloride ethylene glycol with a platinum ion concentration of 1 mg / L, raise the temperature to 150°C and react for 10 minutes to obtain platinum seed crystals Carbon nanotubes, wherein thiolated carbon nanotubes: ethylene glycol: platinous chloride ethylene glycol solution = 100mg: 100ml: 5ml.

[0018] Step 3: Add 0.1mol / L silver nitrate and 0.6mol / L polyvinylpyrrolidone ethylene glycol solution at the end of the reaction in the previous step, raise the temperature t...

Embodiment 2

[0020] Step 1: Disperse 1g of acidified carbon nanotubes into 150ml of N,N dimethylformamide and sonicate for 2h, then add 1g of p-mercaptobenzoic acid and catalytic equivalent of 4-dimethylaminopyridine, react at 85°C for 24h and pump Filter, wash and dry to obtain mercapto-functionalized carbon nanotubes.

[0021] Step 2: ultrasonically disperse 100 mg of mercaptolated carbon nanotubes into 100 ml of propylene glycol, add 10 ml of platinous chloride propylene glycol solution with a platinum ion concentration of 1 mg / L, and heat up to 150 ° C for 10 minutes to obtain carbon loaded with platinum seeds. nanotube.

[0022] Step 3: Add 10ml of 0.1mol / L silver nitrate and 0.6mol / L propylene glycol solution of polyvinylpyrrolidone at the end of the reaction in the previous step, raise the temperature to 160°C, and react for 2 hours. After the reaction, centrifuge, wash and dry to obtain carbon nano tube composites of silver nanowires grown in situ.

Embodiment 3

[0024] Step 1: Disperse 1g of acidified carbon nanotubes into 150ml of N,N dimethylformamide and sonicate for 2 hours, then add 0.1g of mercaptoethylamine, react at room temperature for 24 hours, then filter, wash and dry to obtain thiol-functionalized carbon nanotubes Tube.

[0025] Step 2: ultrasonically disperse 100mg of mercaptolated carbon nanotubes into 100ml of ethylene glycol, add 10ml of chloroplatinic acid ethylene glycol solution with a platinum ion concentration of 1mg / L, and heat up to 150°C for 10 minutes to obtain loaded platinum crystals species of carbon nanotubes.

[0026] Step 3: Add 0.1mol / L silver nitrate and 1mol / L propylene glycol solution of sodium lauryl sulfate to 10ml respectively at the end of the reaction in the previous step, heat up to 180°C, react for 1h, centrifuge, wash and dry after the reaction to obtain Composites of carbon nanotubes grown in situ with silver nanowires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com